Drilling fluid, preparation method and application thereof

A drilling fluid and inhibitor technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of deepening reservoir damage, long drilling cycle, long soaking time, etc., to control wellbore collapse, reduce Damage, Intrusion Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

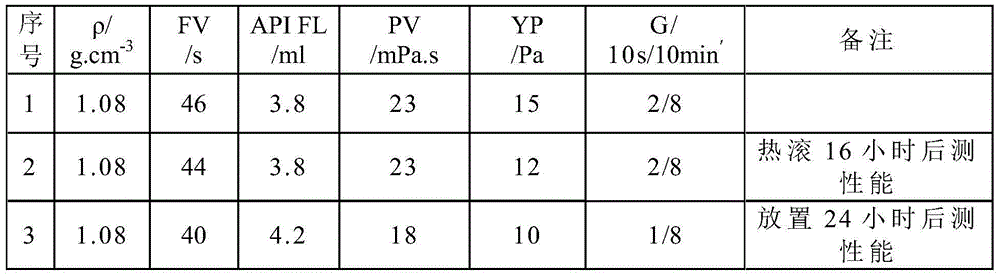

Embodiment 1

[0036] In the present embodiment, the composition of the drilling fluid and the percentage by weight of each component are as follows:

[0037] 1% plugging agent G314-FDJ;

[0038] 7% inorganic salt inhibitor KCl;

[0039] 0.35% organic salt inhibitor G319-FTJ;

[0040] 1% acid soluble fluid loss reducer G310-SJS;

[0041] 2.5% acid-soluble temporary plugging agent G302-SZD;

[0042] 0.3% xanthan gum;

[0043] 0.3% high viscosity polyanionic cellulose;

[0044] 0.3% low viscosity polyanionic cellulose;

[0045] The rest is water and an appropriate amount of NaCl;

[0046] Concrete preparation process is as follows:

[0047] According to the weight percentage of the above components, first add high-viscosity polyanionic cellulose, low-viscosity polyanionic cellulose, and xanthan gum into the water, and fully stir, and the stirring reaction is controlled for 40 to 60 minutes until it is completely dissolved;

[0048] Then add acid-soluble dehydration reducer G310-SJS and...

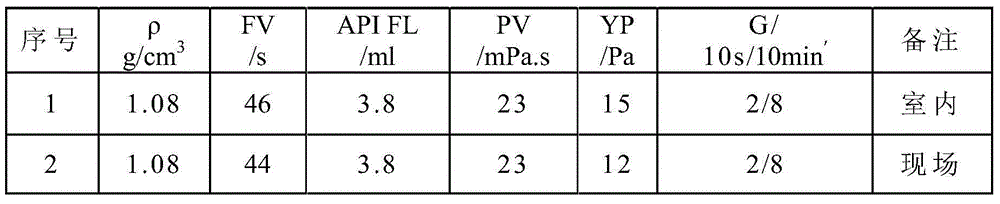

Embodiment 2

[0060]In the present embodiment, the composition of the drilling fluid and the percentage by weight of each component are as follows:

[0061] 1.2% plugging agent G314-FDJ;

[0062] 8% inorganic salt inhibitor KCl;

[0063] 0.4% organic salt inhibitor G319-FTJ;

[0064] 1.2% acid soluble fluid loss reducer G310-SJS;

[0065] 3.0% acid-soluble temporary plugging agent G302-SZD;

[0066] 0.4% xanthan gum;

[0067] 0.4% high viscosity polyanionic cellulose;

[0068] 0.4% low viscosity polyanionic cellulose;

[0069] The rest is water and an appropriate amount of NaCl;

[0070] Concrete preparation process is as follows:

[0071] According to the weight percentage of the above components, first add high-viscosity polyanionic cellulose, low-viscosity polyanionic cellulose, and xanthan gum into the water, and fully stir, and the stirring reaction is controlled for 40 to 60 minutes until it is completely dissolved;

[0072] Then add acid-soluble dehydration reducer G310-SJS a...

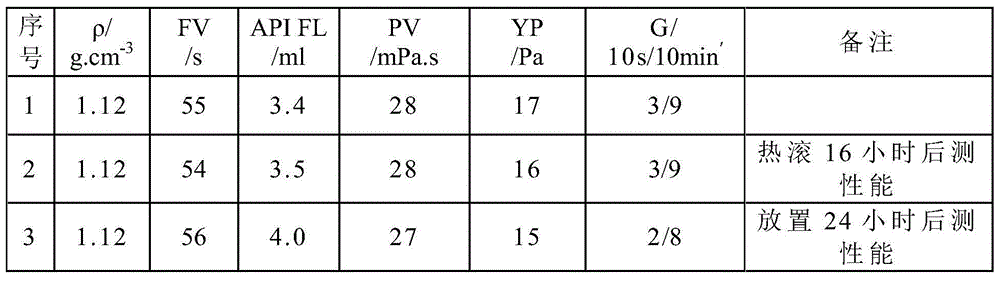

Embodiment 3

[0083] In the present embodiment, the composition of the drilling fluid and the percentage by weight of each component are as follows:

[0084] 1.5% plugging agent G314-FDJ;

[0085] 9% inorganic salt inhibitor KCl;

[0086] 0.45% organic salt inhibitor G319-FTJ;

[0087] 1.5% acid soluble fluid loss reducer G310-SJS;

[0088] 4.0% acid-soluble temporary plugging agent G302-SZD;

[0089] 0.5% xanthan gum;

[0090] 0.5% high viscosity polyanionic cellulose;

[0091] 0.5% low viscosity polyanionic cellulose;

[0092] The rest is water and an appropriate amount of NaCl;

[0093] Concrete preparation process is as follows:

[0094] According to the weight percentage of the above components, first add high-viscosity polyanionic cellulose, low-viscosity polyanionic cellulose, and xanthan gum into the water, and fully stir, and the stirring reaction is controlled for 40 to 60 minutes until it is completely dissolved;

[0095] Then add acid-soluble dehydration reducer G310-SJS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com