Temperature-sensitive hydrogel leak-plugging agent and preparation method and application thereof

A technology of hydrogel and plugging agent, which is applied in the field of temperature-sensitive hydrogel plugging agent and its preparation, and can solve problems such as low pressure bearing capacity, different functions and effectiveness, and great influence on the performance of the plugging agent. , to achieve the effects of preventing repeated leakage, good leakage prevention and plugging, and improved pressure bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

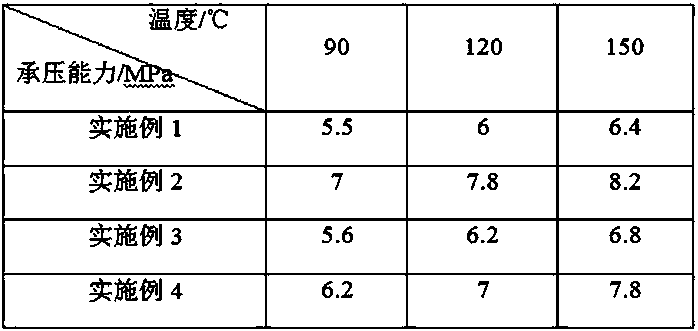

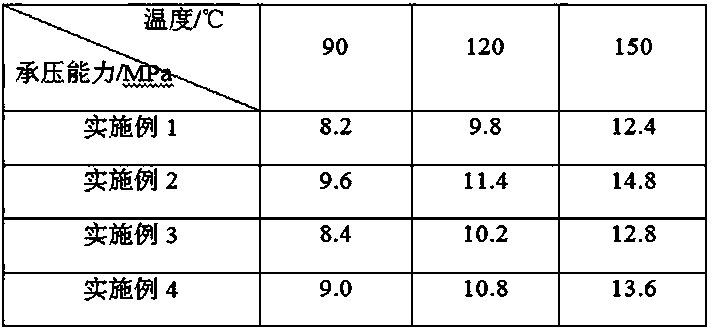

Embodiment 1

[0025] A temperature-sensitive hydrogel plugging agent, consisting of the following raw materials in parts by weight:

[0026] Natural starch: 4 parts potato starch,

[0027] Non-ionic monomer: 6 parts of acrylamide, 2 parts of N-isopropylacrylamide,

[0028] Anionic monomer: 2 parts of 2-acrylamido-2-methylpropanesulfonic acid,

[0029] Crosslinking agent: 0.08 parts of N,N-methylenebisacrylamide,

[0030] Initiator: 0.15 parts of ammonium persulfate,

[0031] pH adjuster: 5 parts of sodium hydroxide solution with a mass concentration of 20%,

[0032] Deionized water: 85 parts.

[0033] The preparation method of described thermosensitive hydrogel plugging agent, comprises the following steps:

[0034] (1) Divide 85 parts of deionized water into three parts, namely 70 parts, 5 parts and 10 parts;

[0035] (2) Dissolve natural starch in 70 parts of deionized water, stir at 70°C and 200 rpm for 20 minutes to gelatinize, and obtain pregelatinized starch;

[0036] (3) Add t...

Embodiment 2

[0040] A temperature-sensitive hydrogel plugging agent, consisting of the following raw materials in parts by weight:

[0041] Natural starch: 8 parts tapioca starch,

[0042] Non-ionic monomer: 6 parts of N-vinylpyrrolidone, 2 parts of N-isopropylacrylamide,

[0043] Anionic monomer: 3 parts of acrylic acid,

[0044] Cross-linking agent: 0.1 part of N,N-methylenebisacrylamide,

[0045] Initiator: 0.3 parts of potassium persulfate,

[0046] pH adjuster: 6 parts of sodium hydroxide solution with a mass concentration of 20%,

[0047] Deionized water: 85 parts.

[0048] The preparation method of described thermosensitive hydrogel plugging agent, comprises the following steps:

[0049] (1) Divide 85 parts of deionized water into three parts, namely 70 parts, 5 parts and 10 parts;

[0050] (2) Dissolve natural starch in 70 parts of deionized water, stir at 80°C and 200 rpm for 50 minutes for gelatinization, and obtain pregelatinized starch;

[0051] (3) Add the initiator to ...

Embodiment 3

[0055] A temperature-sensitive hydrogel plugging agent, consisting of the following raw materials in parts by weight:

[0056] Natural starch: 3 parts glutinous rice starch,

[0057] Non-ionic monomer: 5 parts of acrylamide,

[0058] Anionic monomer: 1 part of acrylic acid,

[0059] Cross-linking agent: 0.06 parts of N,N-methylenebisacrylamide,

[0060] Initiator: 0.1 parts of sodium bisulfite,

[0061] pH regulator: 8 parts of sodium hydroxide solution with a mass concentration of 20%,

[0062] Deionized water: 85 parts.

[0063] The preparation method of described thermosensitive hydrogel plugging agent, comprises the following steps:

[0064] (1) Divide 85 parts of deionized water into three parts, namely 70 parts, 5 parts and 10 parts;

[0065] (2) Dissolve natural starch in 70 parts of deionized water, stir at 90°C and 200 rpm for 30 minutes for gelatinization, and obtain pregelatinized starch;

[0066] (3) Add the initiator to 5 parts of deionized water, cool the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com