An oil-soluble temperature-sensitive resin plugging agent for protecting reservoirs, its preparation method and application

A technology of oil-soluble and plugging agent, applied in the field of drilling fluid plugging, can solve problems such as failure to protect oil and gas layers well, poor high temperature resistance of water plugging agent, inability to use in different formations, etc., so as to widen the softening point temperature range. , cost saving, easy production and on-site operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] An oil-soluble temperature-sensitive resin plugging agent for protecting reservoirs, comprising the following raw materials in parts by weight: 51 parts of resin matrix, 27 parts of modified asphalt, 8 parts of viscosity regulator, 2.5 parts of crosslinking agent, and 10 parts of softening point regulator Parts, dispersant 1.5 parts.

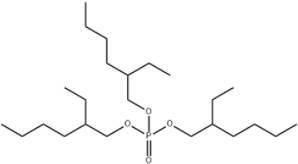

[0060] Wherein, the resin matrix is a combination of oil-soluble phenolic resin and rosin resin, and the mass ratio of oil-soluble phenolic resin and rosin resin is 1:2; the viscosity regulator is a combination of ethylene bis-stearic acid amide and oxidized polyethylene wax, The mass ratio of ethylene bis stearic acid amide and oxidized polyethylene wax is 1:2; the softening point regulator is a combination of dihydrorosin and perhydrorosin, and the mass ratio of dihydrorosin and perhydrorosin is 1:1 ; The crosslinking agent is epoxy resin; the dispersant is sodium dodecylsulfonate.

[0061] Modified asphalt is prepared according to t...

Embodiment 2

[0070] An oil-soluble temperature-sensitive resin plugging agent for protecting reservoirs, comprising the following raw materials in parts by weight: 53 parts of resin matrix, 27 parts of modified asphalt, 8 parts of viscosity regulator, 2.5 parts of crosslinking agent, and 8 parts of softening point regulator Parts, dispersant 1.5 parts.

[0071] Wherein, the resin matrix is a combination of oil-soluble phenolic resin and rosin resin, and the mass ratio of oil-soluble phenolic resin and rosin resin is 1:2; the viscosity regulator is a combination of ethylene bis-stearic acid amide and oxidized polyethylene wax, The mass ratio of ethylene bis stearic acid amide and oxidized polyethylene wax is 1:2; the softening point regulator is a combination of dihydrorosin and perhydrorosin, and the mass ratio of dihydrorosin and perhydrorosin is 1:1 ; The crosslinking agent is epoxy resin; the dispersant is sodium dodecylsulfonate.

[0072] The preparation method of the modified aspha...

Embodiment 3

[0075] An oil-soluble temperature-sensitive resin plugging agent for protecting reservoirs, comprising the following raw materials in parts by weight: 53 parts of resin matrix, 27 parts of modified asphalt, 6 parts of viscosity regulator, 2.5 parts of crosslinking agent, and 10 parts of softening point regulator Parts, dispersant 1.5 parts.

[0076] Wherein, the resin matrix is a combination of oil-soluble phenolic resin and rosin resin, and the mass ratio of oil-soluble phenolic resin and rosin resin is 1:2; the viscosity regulator is a combination of ethylene bis-stearic acid amide and oxidized polyethylene wax, The mass ratio of ethylene bis stearic acid amide and oxidized polyethylene wax is 1:2; the softening point regulator is a combination of dihydrorosin and perhydrorosin, and the mass ratio of dihydrorosin and perhydrorosin is 1:1 ; The crosslinking agent is epoxy resin; the dispersant is sodium dodecylsulfonate.

[0077] The preparation method of the modified asph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com