Water-based drilling fluid

A water-based drilling fluid and clean water technology, applied in the direction of drilling compositions, chemical instruments and methods, can solve problems such as hydrolysis and oxidation stability, low-temperature fluidity foaming, etc. stable, low environmental impact, and low unit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] As a preferred embodiment of the present invention, it discloses a water-based drilling fluid, which is prepared from clear water, inhibitors, fluid loss reducers, plugging agents, pH regulators, and weighting agents in parts by weight , clear water: inhibitor: fluid loss reducer: plugging agent: pH regulator: weighting agent=100:20~25:15~20:1~2:0.5~1:35~200.

[0024] The inhibitor is composed of 0.2 to 1 parts by weight of potassium polyacrylate KPAM, 0.5 to 2 parts by weight of polyanionic cellulose PAC-LV, and 0.3 to 2 parts by weight of inhibitor organosilicon aluminum QLA for high solid phase drilling fluid. , 10-20 parts by weight of potassium formate and 3-8 parts by weight of potassium chloride are mixed.

[0025] The fluid loss reducer is prepared by mixing 2-4 parts by weight of sulfonated phenolic resin SMP and 1-2 parts by weight of high temperature and salt resistant fluid loss reducer RSTF.

[0026] The plugging agent is shale inhibitor SOLTEX; the pH reg...

Embodiment approach

[0030] As a best embodiment of the present invention, its preparation method is as follows: take clear water, inhibitor, fluid loss control agent, plugging agent, stabilizer, pH regulator, weighting agent.

[0031] The specific ratio is: 400ml water, 1.2g KPAM, 3.2g PAC-LV, 2g QLA, 20g potassium chloride, 40g potassium formate, 40g SMP-1, 20g RSTF, 4g SOLTEX, 2g quicklime Weighted to 1.4g / cm 3 . After being fully stirred and mixed at 11000r / min, it was aged in a roller furnace at 100°C for 16 hours.

[0032] The measurement of basic performance parameters at 55°C is shown in Table 1:

[0033]

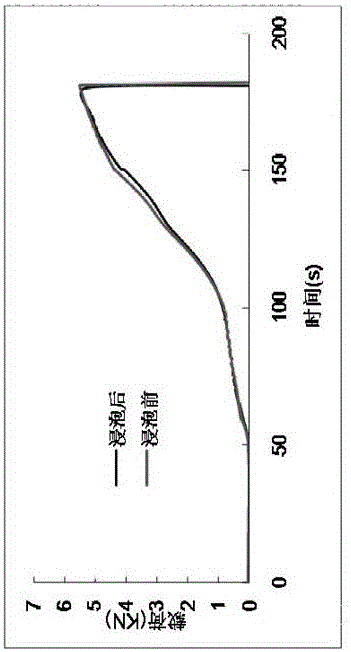

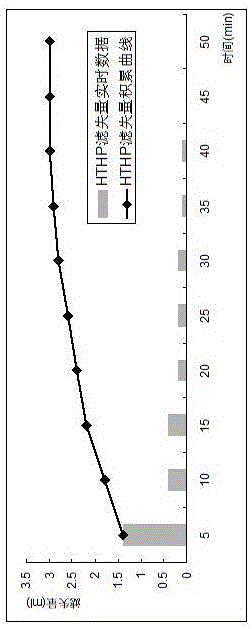

[0034] refer to figure 1 , The high-temperature and high-pressure filtration loss decreased significantly after 5 minutes and gradually decreased to zero after 40 minutes, achieving a good immediate plugging effect. Take out the formed filter cake, replace the drilling fluid with clean water and put it into the prepared high-performance drilling fluid high-temperature and high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com