Automatic crawling trolley for detection in pipeline

An automatic crawling and trolley technology, used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as inability to climb, walk, and prevent slippage, and achieve the effect of efficient blockage removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The utility model relates to an automatic crawling trolley for in-pipeline inspection and a crawling camera inspection device for in-pipeline.

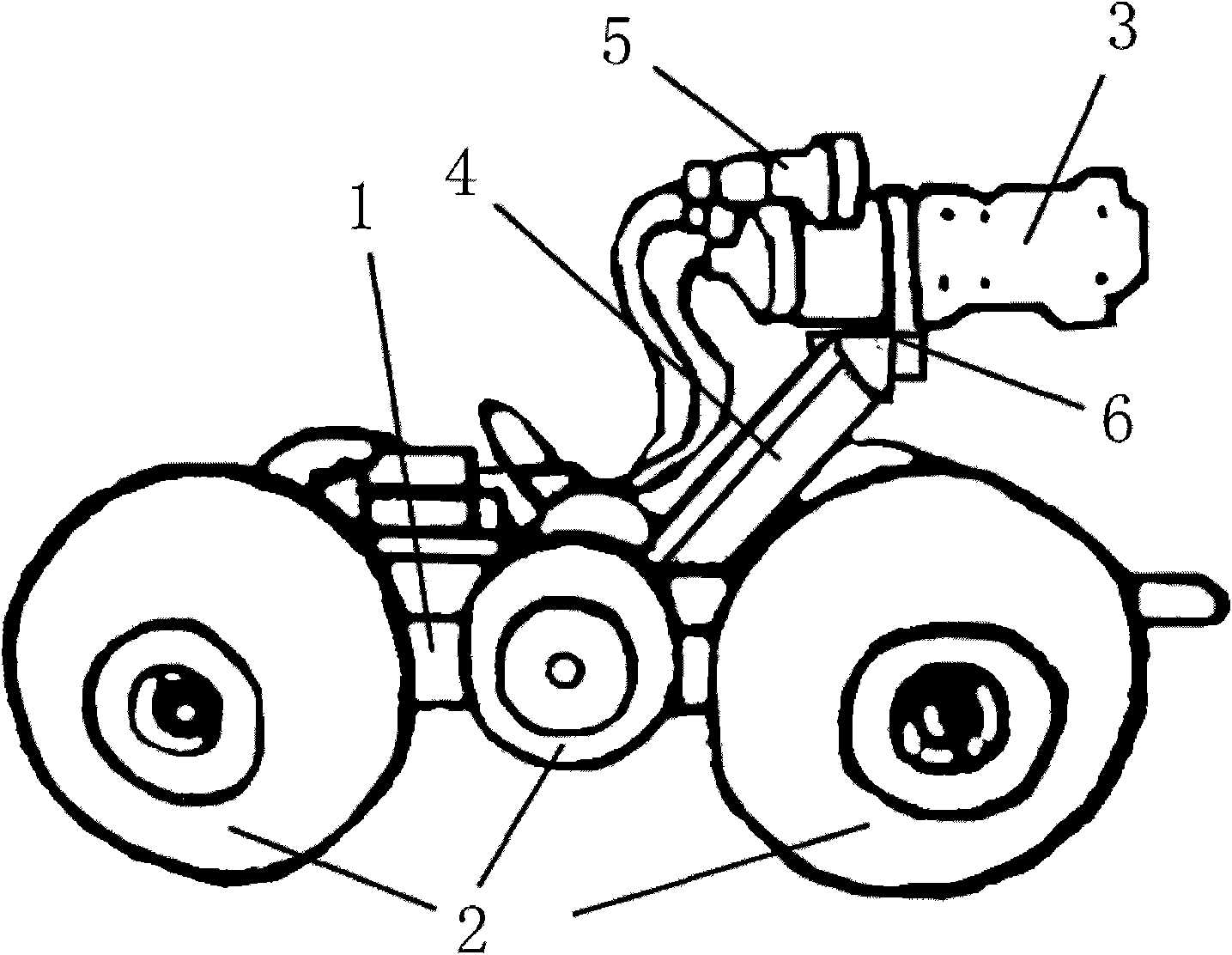

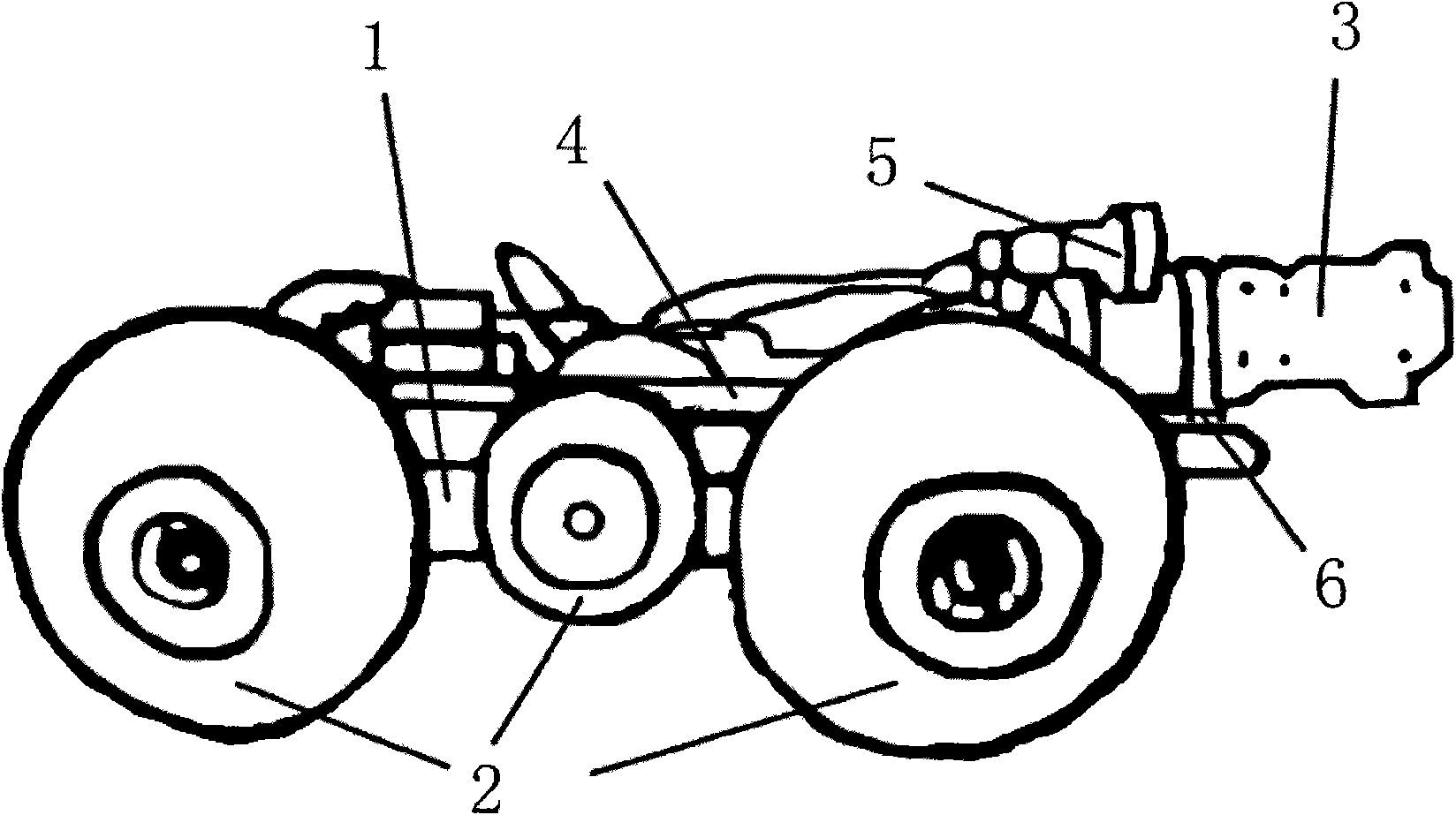

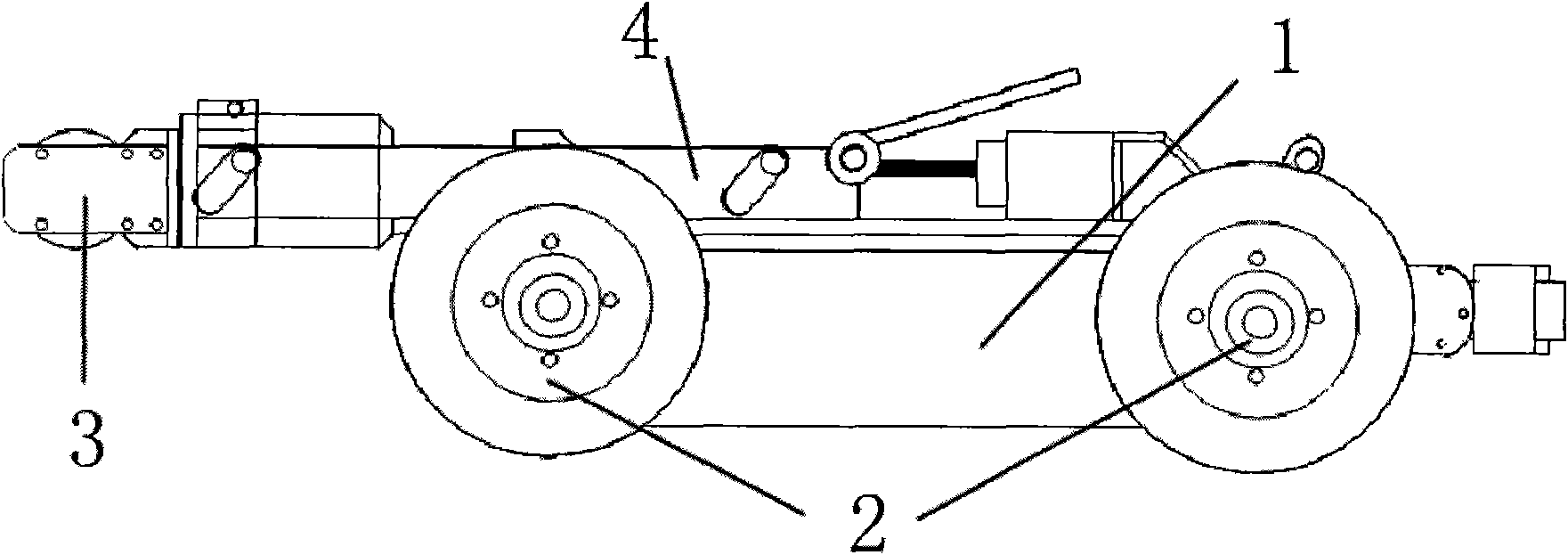

[0044] The automatic crawling trolley for detection in the pipeline of this embodiment includes a vehicle frame 1 and four traveling wheels 2 installed on both sides thereof, the traveling wheels 2 on both sides of the automatic crawling trolley are independently driven respectively, and the vehicle frame 1 is provided with a monitoring device 3 and its supporting rod 4.

[0045] In the automatic crawling trolley for detection in the pipeline of this embodiment, illuminating lamps 5 are installed on its two sides, and the detection device can rotate in the horizontal direction around the pivot point 6 at the upper end of the support rod 4. Manipulate the main controller of the control. The size of the trolley of the crawling camera detection device is 600mm in length, 180mm in height and 180mm in width.

[0046] The diameter ...

Embodiment 2

[0055] A non-excavation repair project for underground pipelines of industrial sewage pipes in a section of Shanghai.

[0056] Type of pipe: reinforced concrete pipe, 9 sections in total, 334.0 meters, 2 inspection wells.

[0057] Pipeline burial depth: about 3.0-3.3 meters, groundwater level: GL-1.0m.

[0058] Due to the heavy traffic on this section of the road, if large-scale excavation is used for repairs, the traffic will be seriously affected. Moreover, the construction period is long, the construction noise is large, and there is a lot of construction waste, which also has a great impact on the factory production and the surrounding environment.

[0059] Therefore, the trenchless repair technology, that is, the trenchless repair method of the underground pipeline of the present invention is adopted to repair the pipeline as a whole.

[0060] First, through CCTV camera detection, use a crawling camera detection device with the automatic crawling trolley for detection i...

Embodiment 3

[0064] Except that the automatic crawling trolley can be independently driven by the six traveling wheels 2 on both sides, the crawling trolley size: 450×160×80mm. The diameter of the large traveling wheel of the automatic crawling trolley for detection in the pipeline is 170 mm, the diameter of the middle traveling wheel is 120 mm, and the diameter of the small traveling wheel is 80 mm.

[0065] Except for the detection in the pipeline whose internal diameter is 150mm, other detections are carried out as in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com