Preparation method of biomedical porous titanium

A biomedical, porous titanium technology, applied in the field of biomedical porous titanium preparation, can solve the problem of affecting the biological and mechanical compatibility of biomedical porous titanium, affecting the bonding strength and osteogenic activity of implants and osseointegration, and the difficulty of porous titanium. Controlling pore size and porosity to achieve controllable pore parameters, eliminate stress-shielding, and avoid loosening or fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

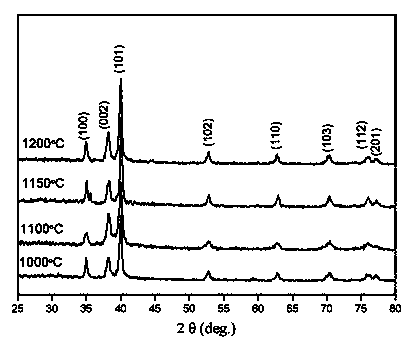

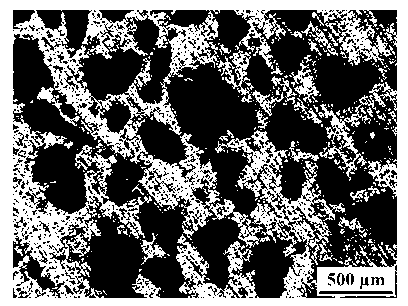

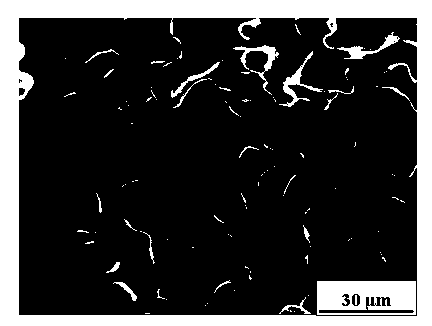

[0021] This embodiment provides a method for preparing biomedical porous titanium by spark plasma sintering, which specifically includes the following steps:

[0022] (1) According to Ti 80%, NH 4 HCO 3 20% by mass percentage, respectively weigh Ti metal powder with a particle size of 45 μm and a purity of 99.5% and NH with a particle size of 300 μm and a purity of analytically pure 4 HCO 3 Porogen powder;

[0023] (2) Put the powder weighed in step (1) into the mixer and mix for 30 minutes to obtain the mixed powder;

[0024] (3) Put the mixed powder obtained in step (2) into a stainless steel mold, apply a unidirectional pressure of 100 MPa through the indenter, and retreat the mold after cold pressing to obtain a block compact;

[0025] (4) Put the block compact obtained in step (3) into a cylindrical graphite mold, place it in a spark plasma sintering furnace, vacuumize the system to 6Pa and then sinter, and heat it at a heating rate of 100°C / min to After the sinteri...

Embodiment 2

[0031] This embodiment provides a method for preparing biomedical porous titanium by spark plasma sintering, which specifically includes the following steps:

[0032] (1) According to Ti 85%, NH 4HCO 3 15% by mass, respectively weigh Ti metal powder with a particle size of 40 μm and a purity of 99.5% and NH with a particle size of 1000 μm and a purity of analytically pure 4 HCO 3 Porogen powder;

[0033] (2) Put the powder weighed in step (1) into the mixer and mix for 60 minutes to obtain the mixed powder;

[0034] (3) Put the mixed powder obtained in step (2) into a stainless steel mould, apply a unidirectional pressure of 300MPa through the indenter, and retreat the mold after cold pressing to obtain a block compact;

[0035] (4) Put the block compact obtained in step (3) into a cylindrical graphite mold, place it in a spark plasma sintering furnace, vacuumize the system to 2Pa and sinter it, and heat it at a heating rate of 90°C / min to After the sintering temperature...

Embodiment 3

[0040] This embodiment provides a method for preparing biomedical porous titanium by spark plasma sintering, which specifically includes the following steps:

[0041] (1) According to Ti 75%, NH 4 HCO 3 30% by mass, weigh Ti metal powder with a particle size of 25 μm and a purity of 99.5% and NH with a particle size of 500 μm and a purity of analytically pure 4 HCO 3 Porogen powder;

[0042] (2) Put the powder weighed in step (1) into the mixer and mix for 120 minutes to obtain the mixed powder;

[0043] (3) Put the mixed powder obtained in step (2) into a stainless steel mold, apply a unidirectional pressure of 200 MPa through the indenter, and retreat the mold after cold pressing to obtain a block compact;

[0044] (4) Put the block compact obtained in step (3) into a cylindrical graphite mold and place it in a spark plasma sintering furnace. The system is vacuumed to 3Pa and then sintered, and heated at a heating rate of 50°C / min to After the sintering temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength value | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com