A nano-transition metal oxide sensitive slurry and its preparation method and application

A transition metal, oxide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of less cracks and defects in the film layer, good dispersion, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Nano WO 3 For the sensitive slurry prepared for sensitive materials, the mass percentages of each component added are respectively,

[0033] Nano WO 3 : 25%

[0034] Solvent: 50%

[0035] Moisturizer: 10%

[0036] Dispersant: 5%

[0037] Defoamer: 5%

[0038] pH regulator: 5%

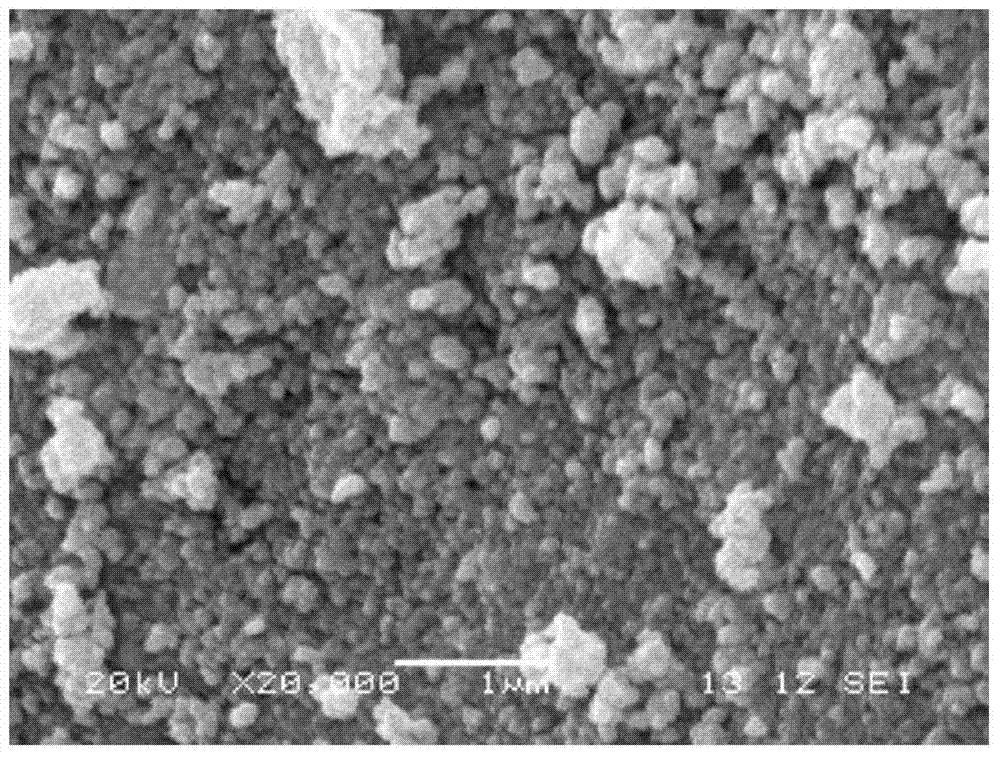

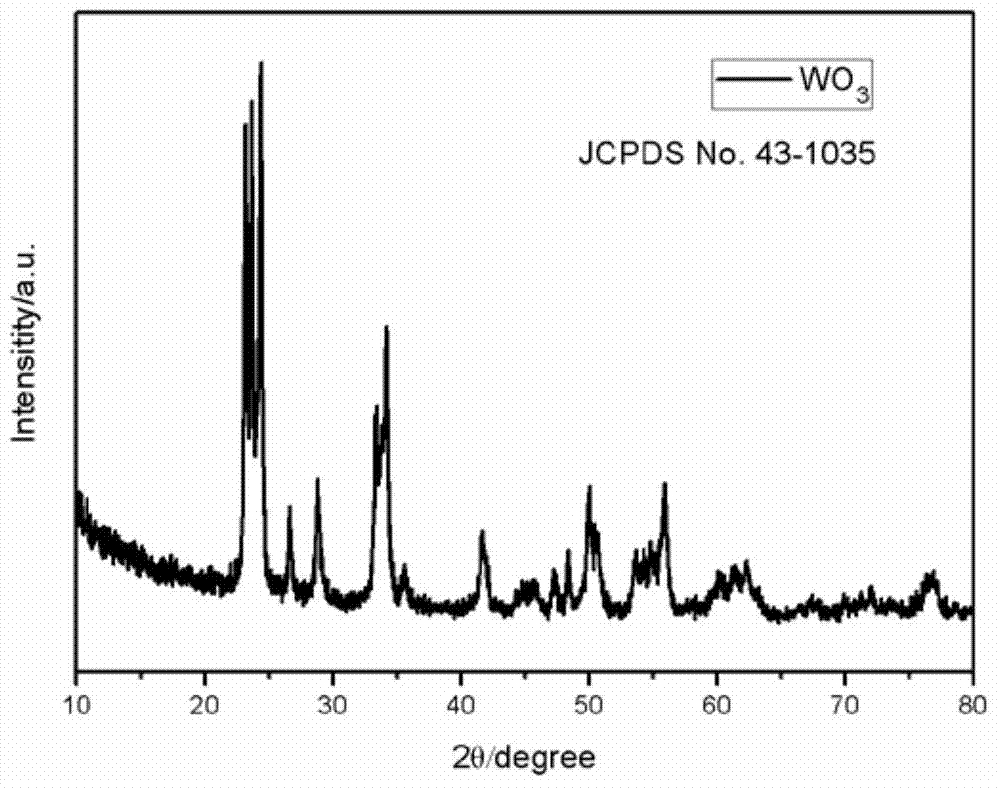

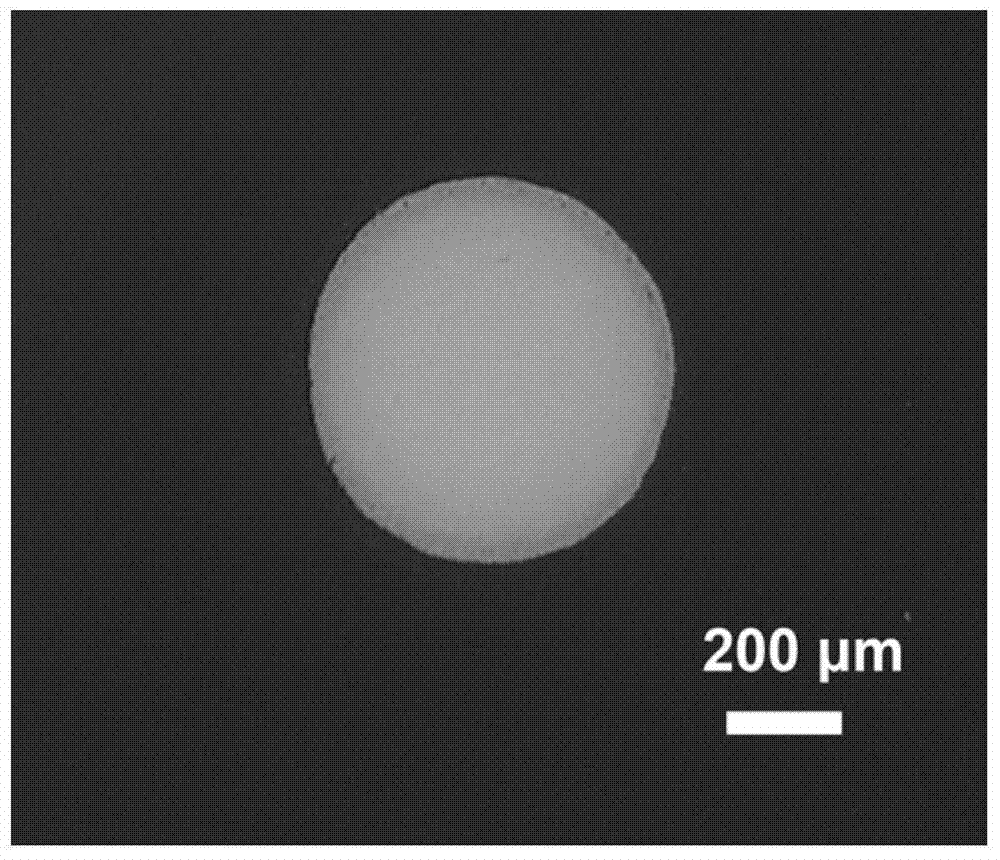

[0039] Among them, Nano WO 3 The particle size of the powder is 50-200nm, the solvent is ethylene glycol, polyethylene glycol, the mass percentage of ethylene glycol:polyethylene glycol is 50%:50%, the moisturizing agent is glycerol, and the dispersant is BYK -180, the defoamer is BYK-354, and the pH regulator is 2-dimethylamino-2-methyl-1-propanol. First, weigh polyethylene glycol, ethylene glycol, and glycerol in proportion, stir with a rotary revolution mixer at 600rpm / min for 5min, and mix well; then, add WO in proportion 3 For sensitive powder materials, stir at 600rpm / min for 5min and mix evenly; finally, add BYK-180, BYK-354, 2-dimethylamino-2-methyl-1-propanol in proportion to ob...

Embodiment 2

[0043] Nano SnO 2 For the sensitive slurry prepared for sensitive materials, the mass percentages of each component added are respectively,

[0044] Nano SnO 2 : 30%

[0045] Solvent: 40%

[0046] Moisturizer: 20%

[0047] Dispersant: 5%

[0048] Defoamer: 3%

[0049] pH regulator: 2%

[0050] Among them, nano-SnO 2 The particle size of the powder is 50-70nm, the solvent is ethylene glycol, polyethylene glycol, water, the mass percentage of ethylene glycol: polyethylene glycol: water is 40%: 40%: 20%, and the moisturizing agent is acrylic acid. Triol, propylene glycol, the mass ratio of glycerol:propylene glycol is 70%:30%, the dispersant is BYK-191, the defoamer is BYK-354, and the pH regulator is ammonia water. First, weigh ethylene glycol, polyethylene glycol, water, and glycerol in proportion, stir with a rotary revolution mixer at 800rpm / min for 5min, and mix well; then, add SnO in proportion 2For sensitive powder materials, stir at 800rpm / min for 5min, and mix e...

Embodiment 3

[0053] Nano In 2 o 3 For the sensitive slurry prepared for sensitive materials, the mass percentages of each component added are respectively,

[0054] Nano In 2 o 3 : 20%

[0055] Solvent: 40%

[0056] Moisturizer: 20%

[0057] Dispersant: 10%

[0058] Defoamer: 5%

[0059] pH regulator: 5%

[0060] Among them, nano In 2 o 3 The particle size of the powder is 50-200nm, the solvent is ethylene glycol, the moisturizing agent is glycerol, the dispersant is BYK-180, the defoamer is n-octanol, and the pH regulator is 2-dimethylamino-2- Methyl-1-propanol. First, weigh ethylene glycol and glycerol in proportion, stir with a rotary revolution mixer at 400rpm / min for 5min, and mix well; then, add In 2 o 3 For sensitive powder materials, stir at 400rpm / min for 5min and mix evenly; finally, add BYK-180, n-octanol, and 2-dimethylamino-2-methyl-1-propanol in proportion to obtain a mixed slurry. Stirring at 1200rpm / min for 10min, and degassing at 1500rpm / min for 5min, the fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com