Continuous circular flow-type optoelectric catalytic fixed bed reactor with 3D electrodes and its organic sewage treating method

A photoelectric catalysis, fixed bed technology, applied in chemical instruments and methods, electrochemical water/sewage treatment, illumination water/sewage treatment, etc. It can reduce the mass transfer effect, save the cost and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

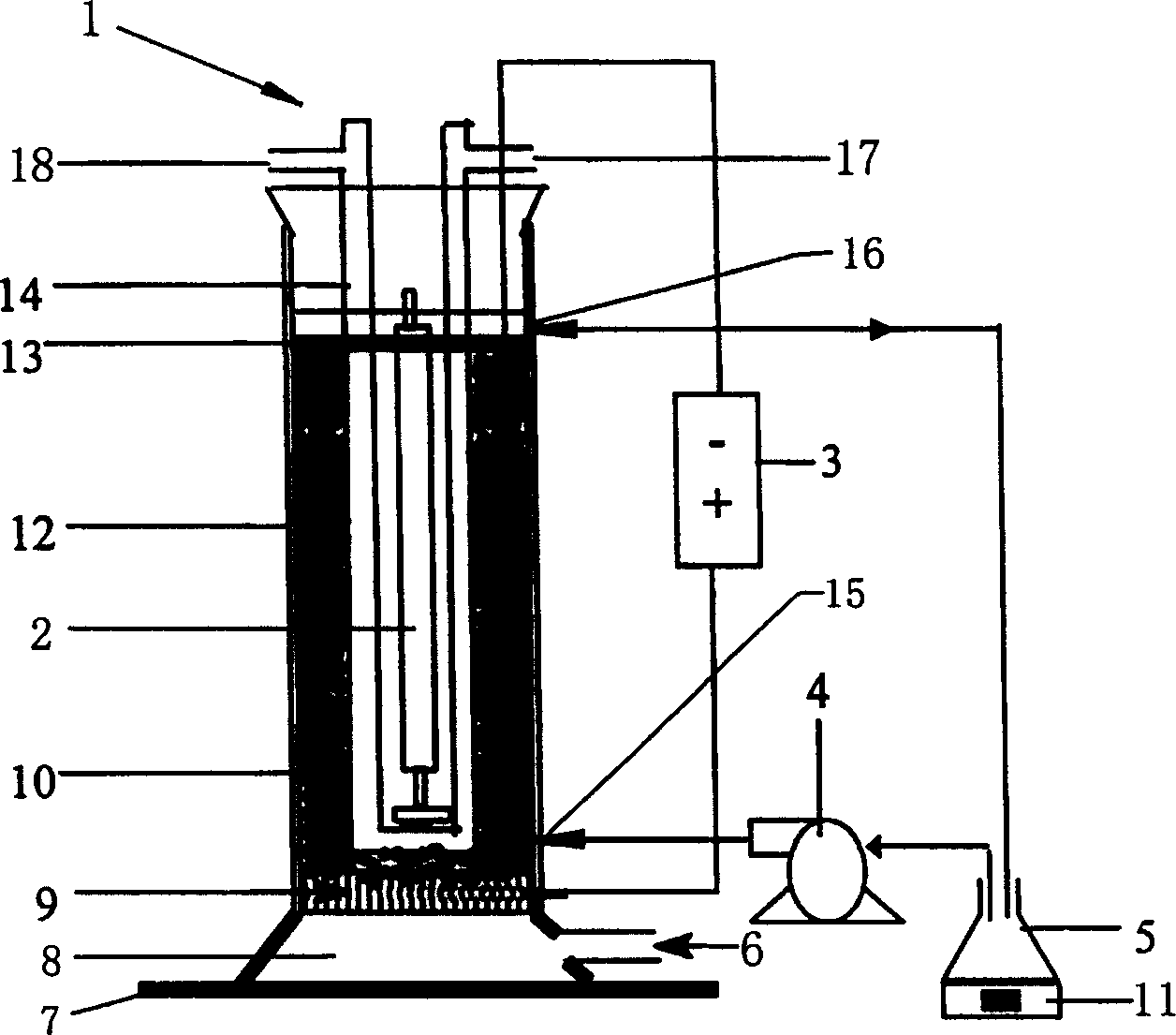

Method used

Image

Examples

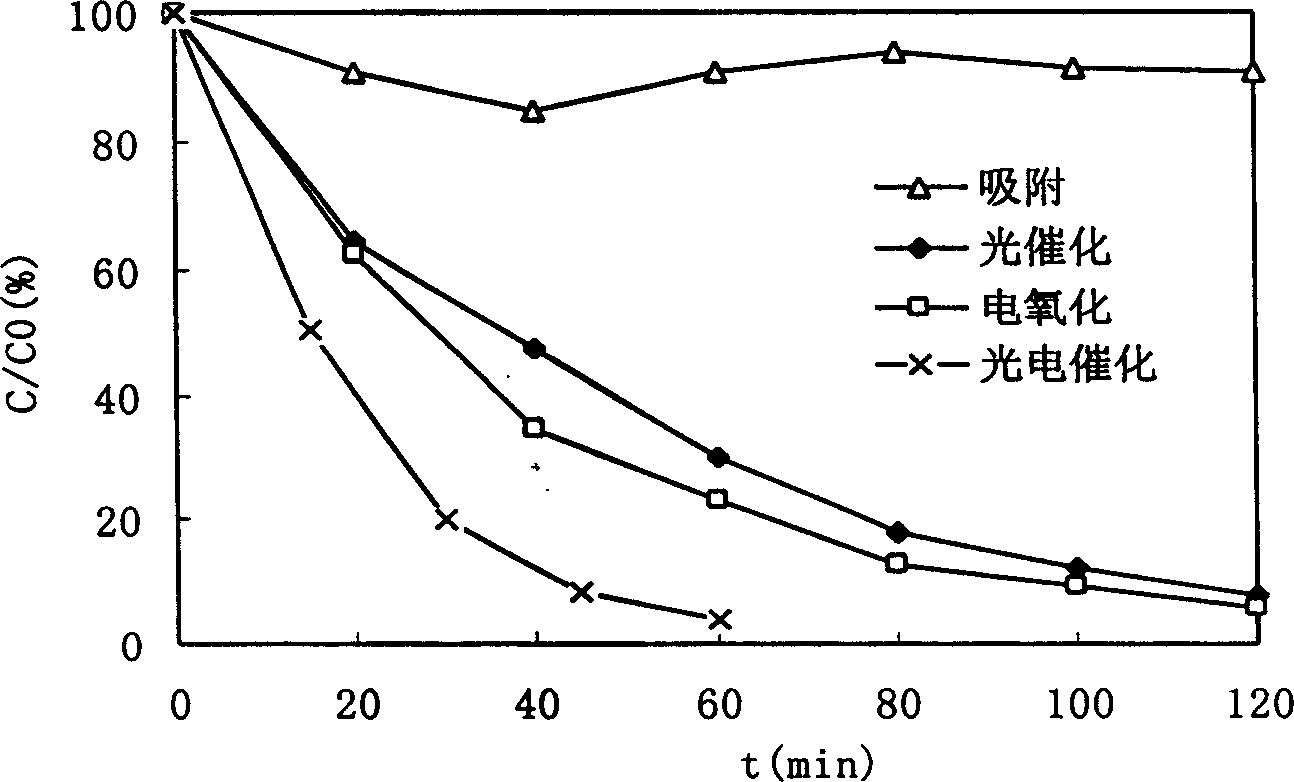

Embodiment 1

[0022] Process the active dye waste liquid of 0.5mmol / L pH value 5.6 with the continuous circulating flow type fixed bed three-dimensional electrode photocatalytic reactor of the present invention, at 30.0V voltage, 0.05MPa air velocity, electrolyte Cl - When the concentration is 0.5mol / L, the removal rate of reactive dyes is 96% when the photocatalytic reaction is 60min, which is higher than 70% and 77% only in photocatalytic and electrochemical oxidation; while TOC The change of and its degradation rate have a similar trend! That is, the TOC removal rate of the reactive dye solution was 61% when the photocatalytic reaction was performed for 150 minutes, which was higher than the 49% and 17% TOC removal rates only in photocatalytic and electrochemical oxidation;

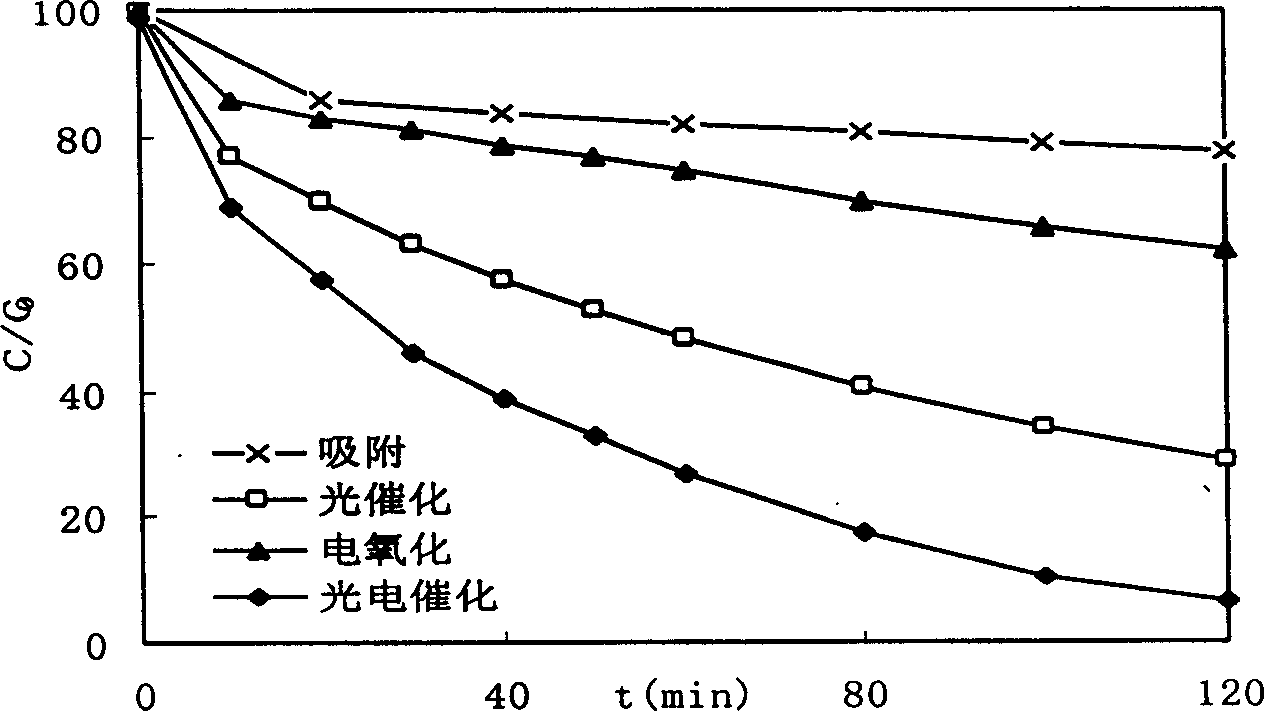

Embodiment 2

[0024] When processing the quinoline solution of 0.25mmol / L pH value 6.8 with the continuous circulating flow type fixed-bed three-dimensional electrode photocatalytic reactor of the present invention, at 30.0V voltage, 0.075MPa air velocity, electrolyte Cl - When the concentration is 0.5mol / L, the removal rate of quinoline is 73% when the photocatalytic reaction is 60min, which is higher than 52% and 26% only in the photocatalytic and electrochemical oxidation; when the photocatalytic reaction is 120min, quinoline The removal rate increased to more than 93%, but it was also higher than 71% and 38% only in photocatalytic and electrochemical oxidation; the change of TOC in the degradation process of quinoline had a similar trend to its degradation rate! That is, the TOC removal rate of the quinoline solution was 41% when the photocatalytic reaction was 60 min, which was higher than the 38% and 7% of the TOC removal rate only in the photocatalytic and electrochemical oxidation; ...

Embodiment 3

[0026] Process the reactive dye waste liquid of 0.5mmol / L pH value 5.6 with the continuous circulating flow type fixed-bed three-dimensional electrode photocatalytic reactor of the present invention, at 0.05MPa air velocity, electrolyte Cl - When the concentration is 0.5mol / L, when the voltage is 10V, the removal rate of active dye is 84% when the photocatalytic reaction is 60min, and when the voltage is increased to 30V, the removal rate of active dye is 96% when the photocatalytic reaction is 60min. The degradation rate of reactive dyes is also from 0.0300min at 10V voltage -10.0539min increased to 30V -1 . During the degradation process of quinoline, the degradation rate and degradation rate of quinoline have a similar trend to that of reactive dyes! Promptly when processing the quinoline solution of 0.25mmol / L pH value 6.8 with the continuous circulating flow type fixed-bed three-dimensional electrode photocatalytic reactor of the present invention, at 0.05MPa air velo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com