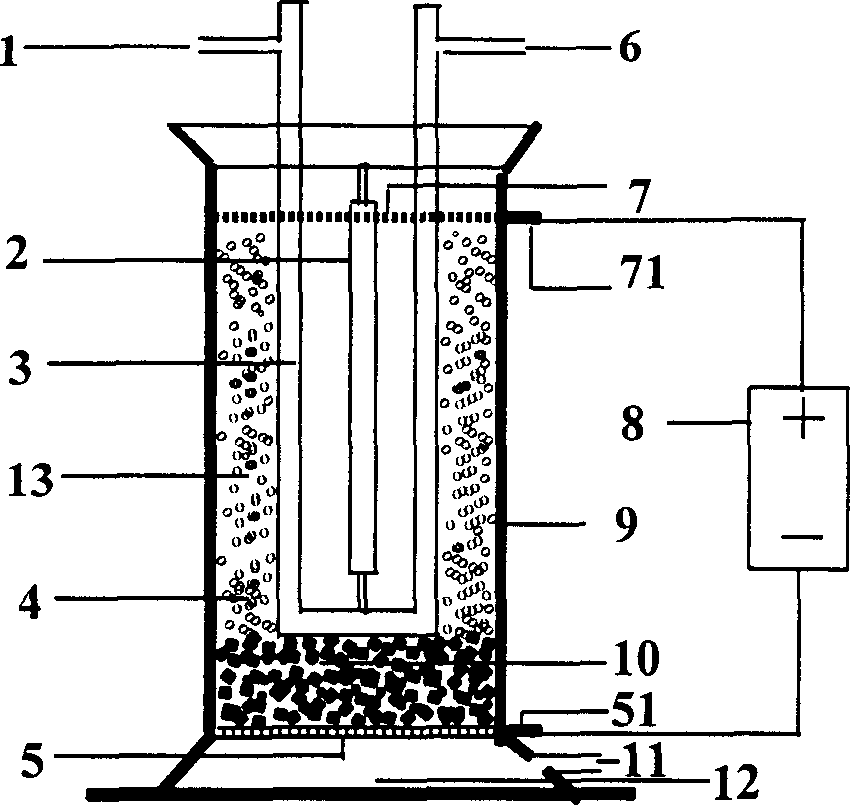

Three phase three-diemsnional electrode photoelectric reactor

A technology of three-dimensional electrodes and reactors, which is applied in the field of three-phase three-dimensional electrode photoelectric reactors, can solve the problems of rare research and achieve the effects of increasing dissolution rate, compact structure and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

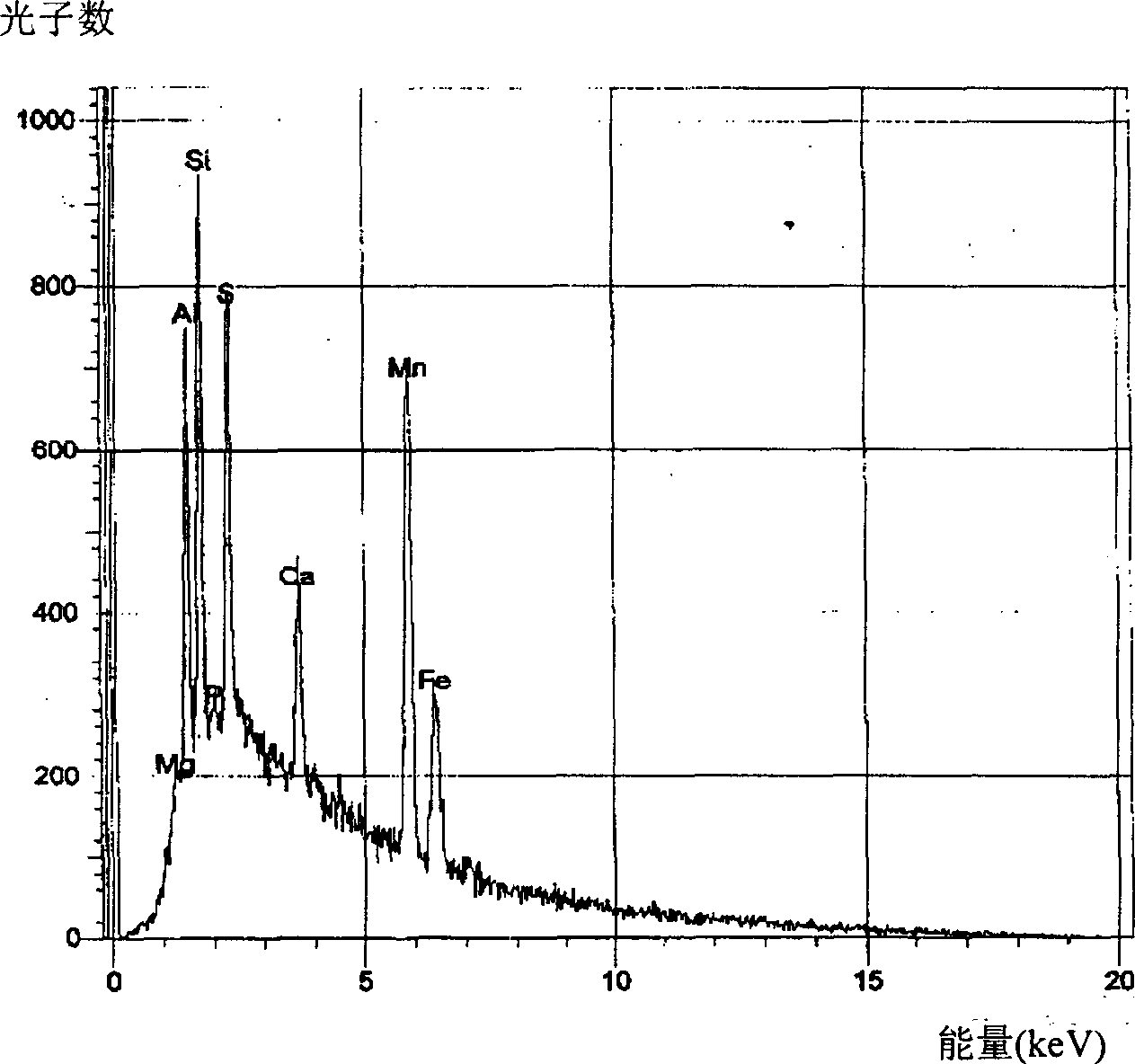

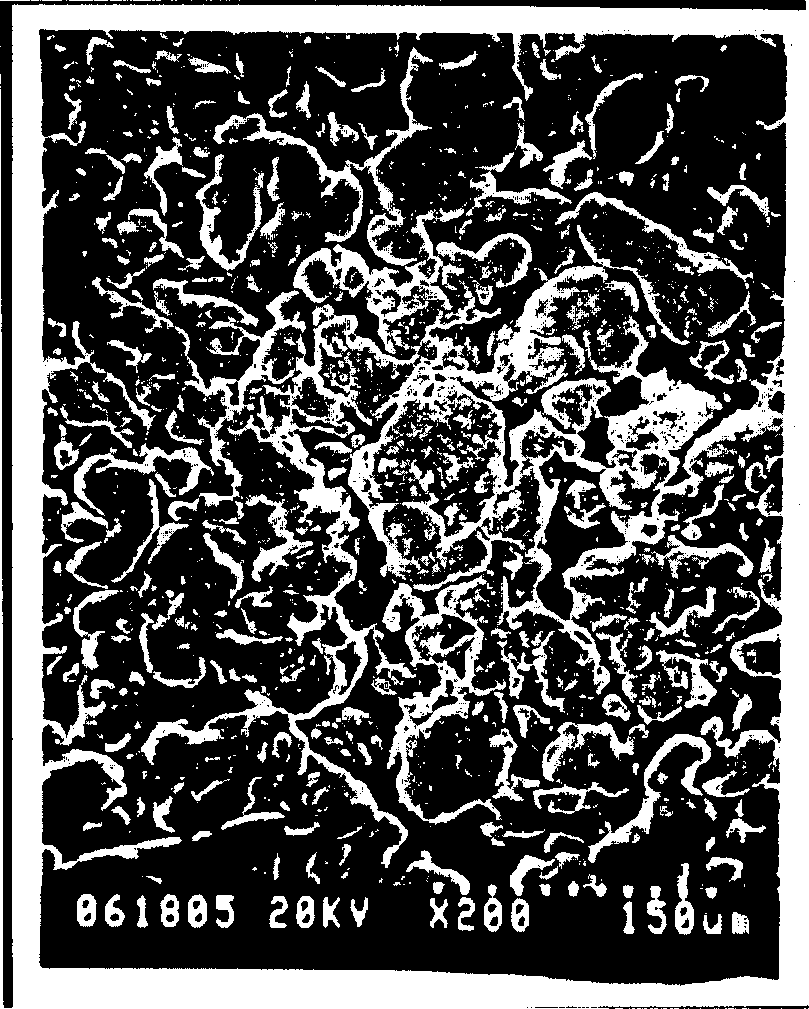

example 1

[0029] A photoelectric reactor with a 4cm bed height of activated carbon packed bed as a three-dimensional electrode is used to treat formic acid wastewater. We found that the COD removal efficiency is related to the applied voltage, and it increases with the increase of the applied voltage. At 10.0 volts, 0.1m 3 h -1 Air flow, 500 watts of high-pressure mercury lamp light and 0.08mgl -1 Degussa P25 TiO 2 In the presence of photocatalyst, after 1 hour of reaction, 20.0mmoll-1 The COD concentration of the formic acid solution from 320.5mgl -1 Down to 118.4mgl -1 , Its removal rate is 62.9%. This removal rate is 35.5% higher than the COD removal efficiency of pure photocatalysis (other conditions are the same except for no voltage).

example 2

[0031] Printing and dyeing wastewater is one of the organic wastewater that is known to be difficult to treat. In addition to COD pollution, it also has color pollution. The photoelectric reactor using a graphite packed bed with a bed height of 3 cm as the three-dimensional electrode can effectively remove the COD and color of dye wastewater. At 30.0 volts, 0.6m 3 h -1 Air flow, 500 watts of high-pressure mercury light and 0.1mgl -1 In the presence of Degussa P25 photocatalyst, 1.0mmoll -1 The photoelectric degradation of methylene blue is in line with the quasi-first order reaction kinetics as its photocatalytic degradation, but the rate constant of the former is 0.088min -1 , Is 1.6 times of the latter. After 0.5 hours of reaction, the solution was completely decolorized, and its COD removal efficiency was 87.2%, and TOC removal efficiency was 81.1%. The removal efficiency of COD and TOC is so close, indicating that methylene blue is almost mineralized.

example 3

[0033] The photoelectric reactor has obvious photoelectric synergy effect in the process of oxidation and decomposition of organic matter. For 20.0mmoll -1 Formic acid solution, 0.1mgl -1 Degussa P25 photocatalyst, 0.2m 3 ·H -1 For a photoreactor with a three-dimensional electrode with an air flow rate and a bed height of 4cm, the photogenerated current at 10 seconds of light is 12.3μA when there is no voltage, and the current at 0.5V and no light is 127.6μA, the photoelectric current when irradiated for 10 seconds under 0.5V voltage is 188.5μA, which exceeds the sum of the current of a single electrochemical and a single photochemical process of 48.6μA. For 20.0mmoll -1 For a photoreactor with a three-dimensional electrode of formic acid solution and a graphite packed bed with a bed height of 4cm, when there is no voltage, the photogenerated current at 10 seconds of light is 15.6μA, and the current at 0.5V and no light is 133.2 μA, the photoelectric current when irradiated for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com