Organic synthesis wastewater low-emission system

An organic synthesis, low-emission technology, used in natural water treatment, special compound water treatment, mechanical vibration water/sewage treatment, etc., can solve the problem of insufficient decomposition of aerobic organic matter, sewage does not achieve the expected effect, and affect the aeration efficiency. and other problems, to achieve the effect of improving the overall current efficiency, improving the oxidation efficiency, and strengthening mutual coupling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

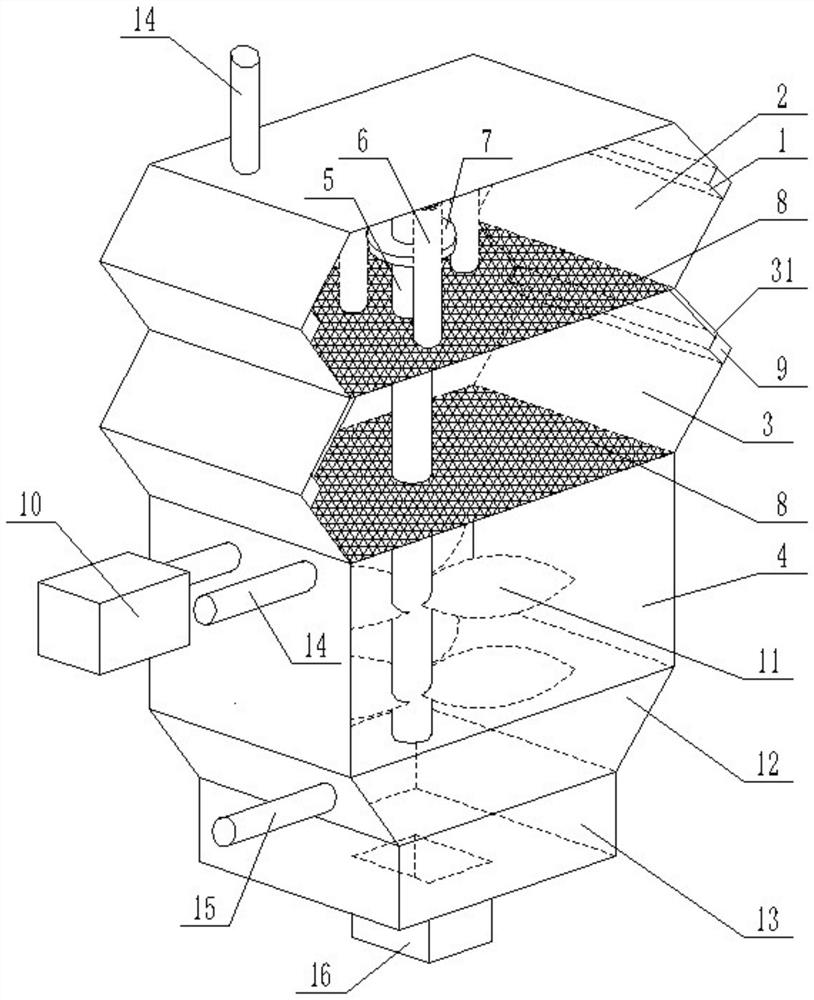

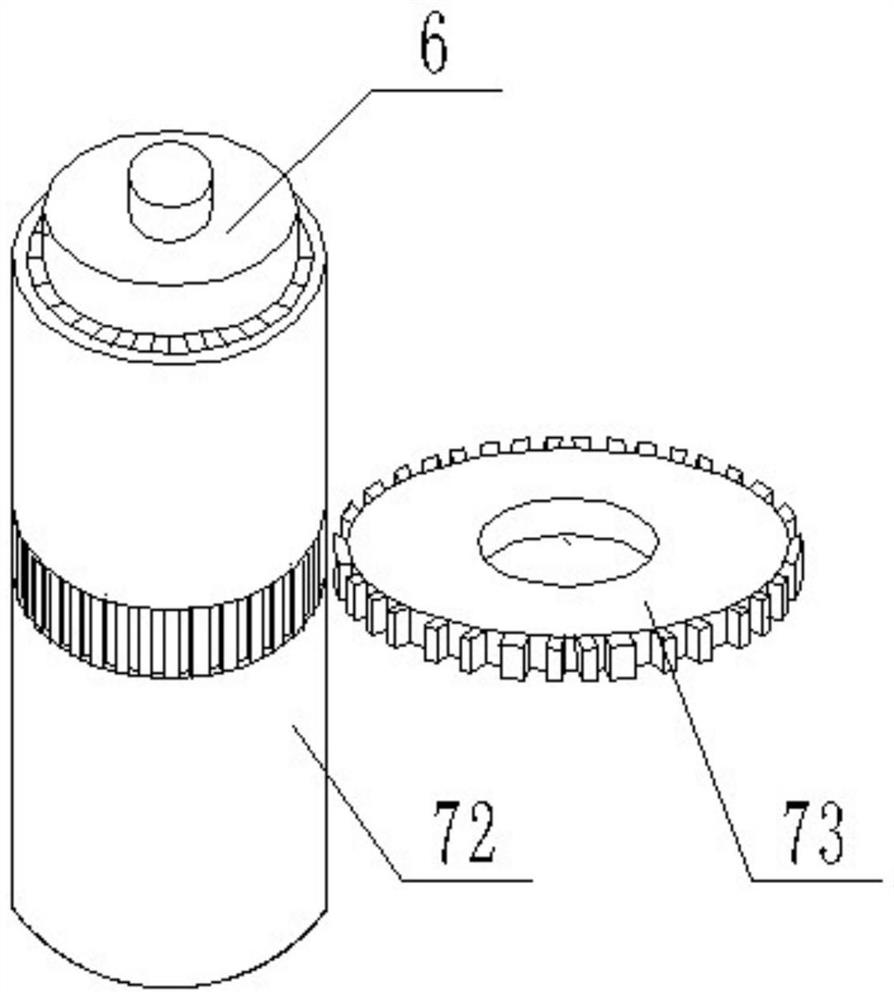

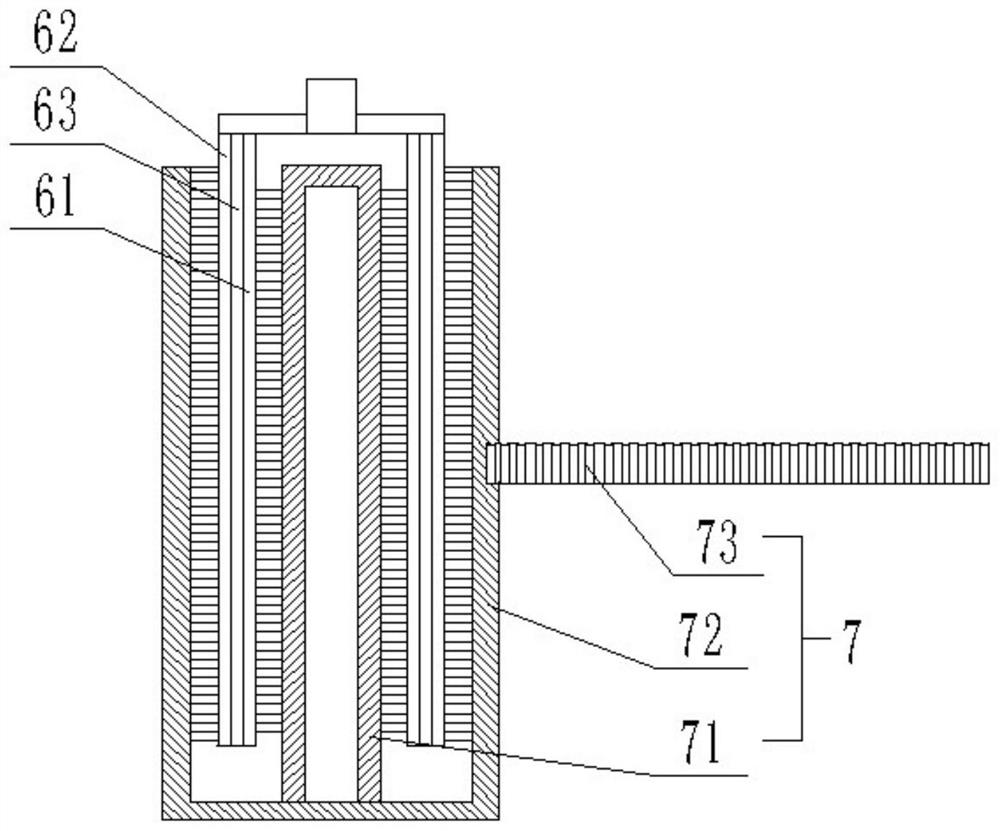

[0021] Such as Figure 1-3 As shown, a low-emission system for organic synthetic wastewater includes a shell, and the shell is divided into an upper radical oxidation zone 2, a photocatalytic reaction zone 3, a lower free radical oxidation zone 4, a settling zone 12 and A buffer zone 13, the upper free radical oxidation zone 2 is provided with a water inlet pipe 14, the settling zone 12 is provided with an outlet pipe 15, the buffer zone 13 is provided with a sludge pipe 16, and the housing is vertically provided with A central rotating shaft 5, the central rotating shaft 5 runs through the upper radical oxidation zone 2, the photocatalytic reaction zone 3 and the lower free radical oxidation zone 4, and the upper radical oxidation zone 2 is provided with a plurality of An electrolysis electrode 6, a cleaning device 7 is provided between the electrolysis electrode 6 and the central rotating shaft 5, a double-layer photocatalytic net 8 is provided in the photocatalytic reaction...

Embodiment 2

[0023] Such as Figure 1-3 As shown, a low-emission system for organic synthetic wastewater includes a shell, and the shell is divided into an upper radical oxidation zone 2, a photocatalytic reaction zone 3, a lower free radical oxidation zone 4, a settling zone 12 and A buffer zone 13, the upper free radical oxidation zone 2 is provided with a water inlet pipe 14, the settling zone 12 is provided with an outlet pipe 15, the buffer zone 13 is provided with a sludge pipe 16, and the housing is vertically provided with A central rotating shaft 5, the central rotating shaft 5 runs through the upper radical oxidation zone 2, the photocatalytic reaction zone 3 and the lower free radical oxidation zone 4, and the upper radical oxidation zone 2 is provided with a plurality of An electrolysis electrode 6, a cleaning device 7 is provided between the electrolysis electrode 6 and the central rotating shaft 5, a double-layer photocatalytic net 8 is provided in the photocatalytic reaction...

Embodiment 3

[0026] Such as Figure 1-3 As shown, a low-emission system for organic synthetic wastewater includes a shell, and the shell is divided into an upper radical oxidation zone 2, a photocatalytic reaction zone 3, a lower free radical oxidation zone 4, a settling zone 12 and A buffer zone 13, the upper free radical oxidation zone 2 is provided with a water inlet pipe 14, the settling zone 12 is provided with an outlet pipe 15, the buffer zone 13 is provided with a sludge pipe 16, and the housing is vertically provided with A central rotating shaft 5, the central rotating shaft 5 runs through the upper radical oxidation zone 2, the photocatalytic reaction zone 3 and the lower free radical oxidation zone 4, and the upper radical oxidation zone 2 is provided with a plurality of An electrolysis electrode 6, a cleaning device 7 is provided between the electrolysis electrode 6 and the central rotating shaft 5, a double-layer photocatalytic net 8 is provided in the photocatalytic reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com