Device and method for electrooxidation of furfural and 5-hydroxymethylfurfural

A technology of hydroxymethylfurfural and electro-oxidation, which is applied in the field of electrochemistry, to achieve the effect of facilitating industrial production and reducing the amount of waste salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

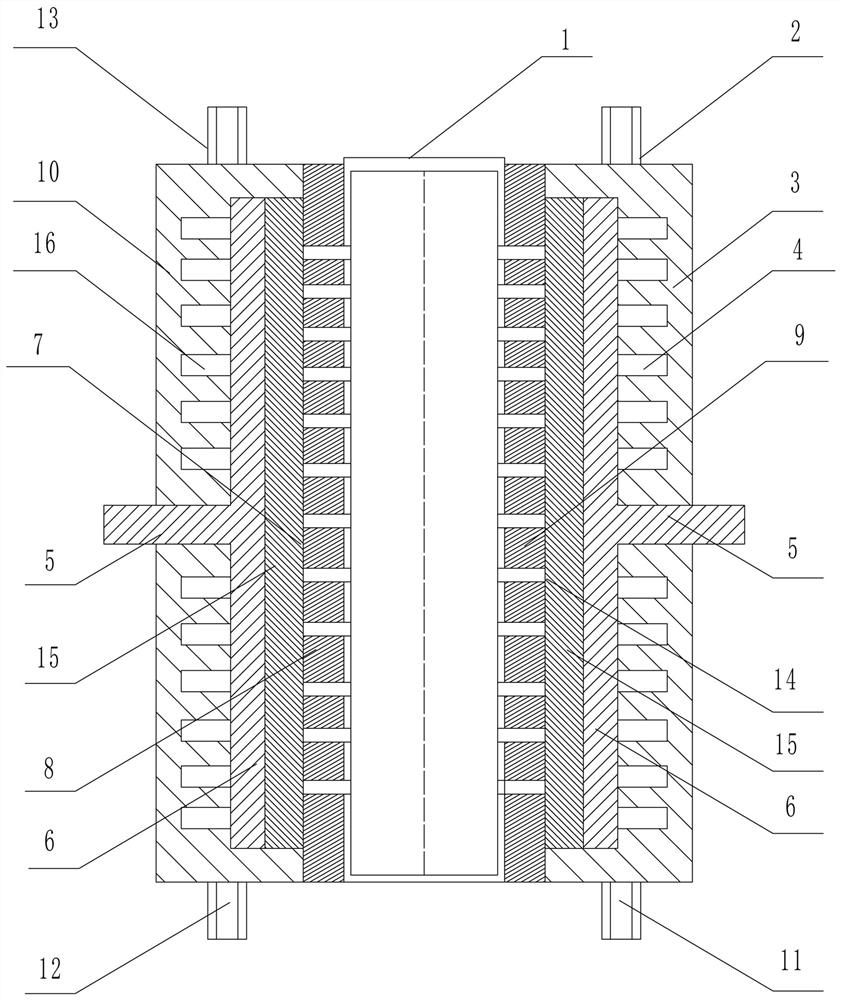

[0043]This embodiment provides a device for electro-oxidation of 5-hydroxymethyl furfural, such as figure 1 As shown, it includes: an anode structure, a cathode structure, and an intermediate cavity 1 for filling and permeating the lye to the outside through the sidewall, and the intermediate cavity 1 is arranged between the anode structure and the cathode structure.

[0044] The anode structure communicates with the intermediate cavity 1 through a layer of anode membrane 9 .

[0045] The cathode structure is communicated with the intermediate cavity 1 through a layer of cathode membrane 8 .

[0046] The anode structure includes an anode cavity 3 with an anode flow channel 4 opened therein, a porous drainage body 6 covering the opening of the anode flow channel 4 to conduct electricity, and a porous support body disposed inside the porous drainage body 6. 15 and the anode catalyst layer 14 coated on the inner side of the porous support body 15 , and the inner side of the anod...

Embodiment 2

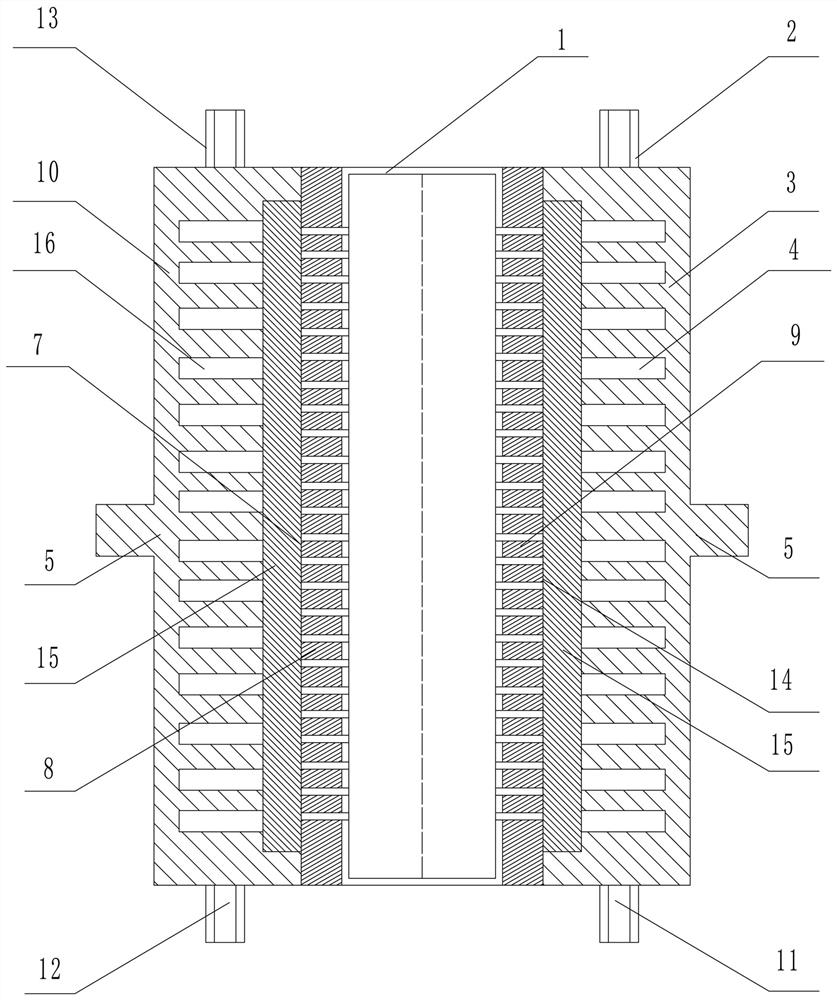

[0079] This embodiment provides a device for electro-oxidation of 5-hydroxymethyl furfural, such as figure 2 As shown, its structure is different from the structure in Example 1 in that:

[0080] In this embodiment, the cathode and anode cavities are both metal cavities, the porous support body is a porous support body made of foamed nickel, and the metal cavity corresponds to the cathode and anode of an external power supply;

[0081] The catalytic layer is connected to the cathode and anode of the corresponding power source through the porous support body made of foamed nickel and the cavity made of metal.

[0082] The present embodiment provides a method of utilizing HMF to prepare FDCA, the steps of which include:

[0083] After stirring the mixed solution of 0.05mol / L HMF and 0.1mol / L NaOH at room temperature, it was mixed into the anode electrolytic cell, and 0.1mol / L NaOH was introduced into the middle cavity to provide the pH required for the reaction; then take the ...

Embodiment 3

[0087] This embodiment provides a device for electro-oxidation of 5-hydroxymethyl furfural, the structure of which is the same as that in Embodiment 2.

[0088] The present embodiment provides a method of utilizing HMF to prepare FDCA, the steps of which include:

[0089] After stirring the mixed solution of 0.05mol / L HMF and 0.1mol / L NaOH at room temperature, it was mixed into the anode electrolytic cell, and 3mol / L NaOH was introduced into the middle cavity to provide the pH required for the reaction, and then take the equimolar concentration with the anode, etc. The volume of NaOH is added to the cathode electrolysis cell;

[0090] to coat Ni(OH) 2 The nickel foam of / CNTs was used as the anode electrode, Hg / HgO was used as the reference electrode, and the nickel foam was used as the cathode electrode.

[0091] After testing, the conversion rate of HMF was 76.4%, the yield of FDCA was 60.5%, the selectivity was 79.2%, and the Faradaic efficiency was 71.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com