Treating method of metallic titanium material

A treatment method and technology of metal titanium, applied in electrolytic inorganic material coating, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of no catalytic activity or low catalytic activity, low conductivity of semiconductor materials, small surface area, etc., to achieve Maintain long-term stable operation, high catalytic activity, and reduce contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

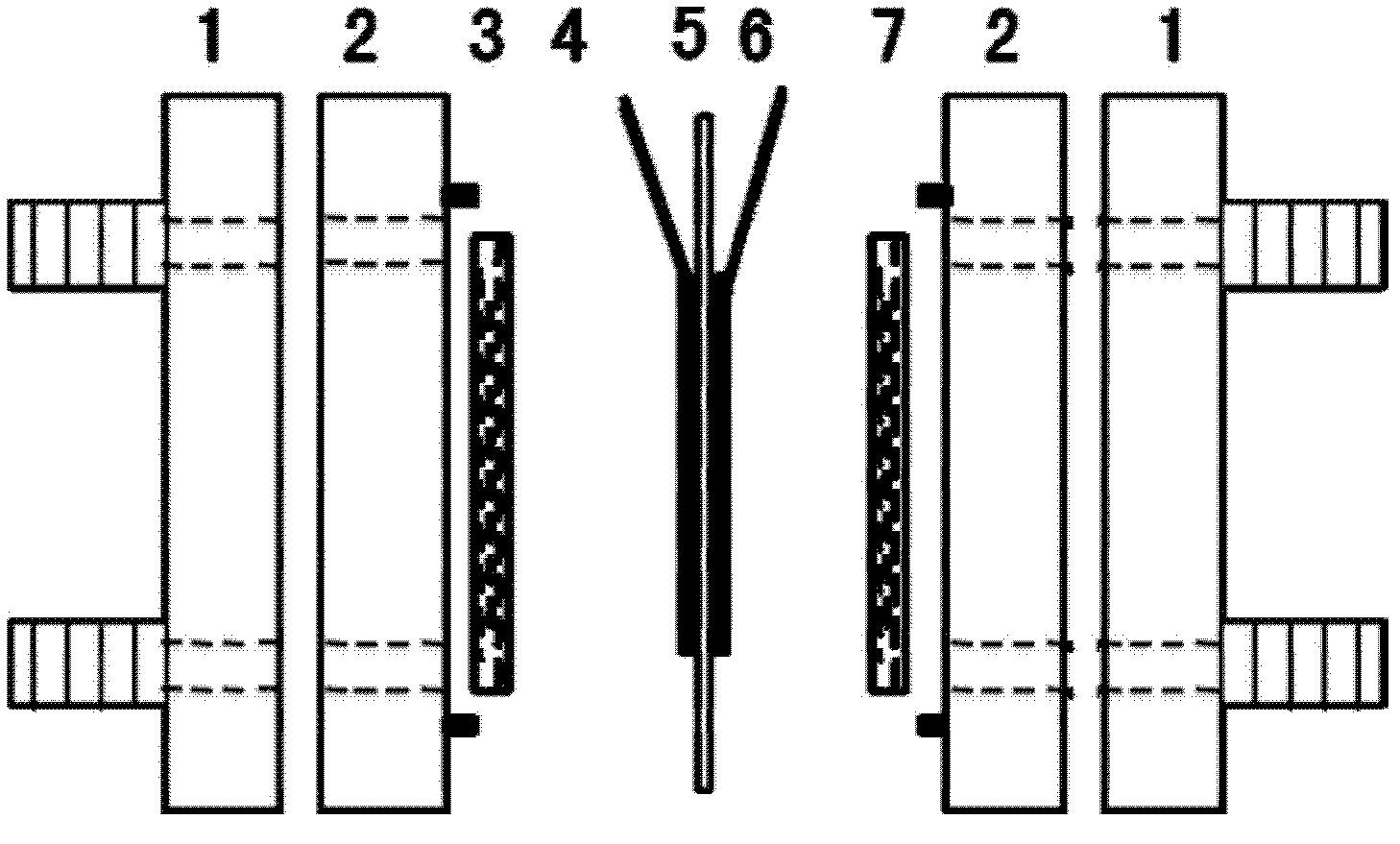

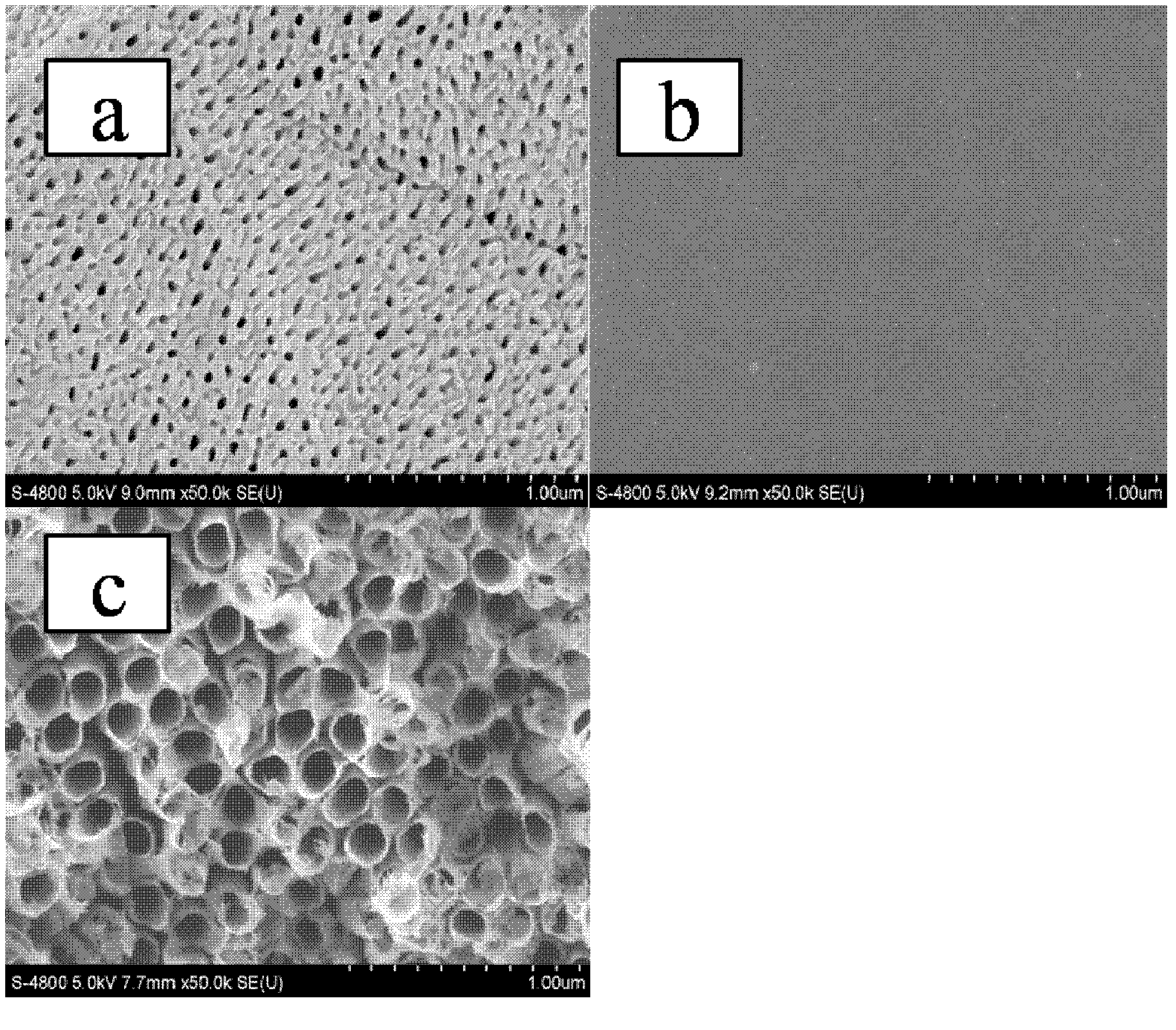

[0040] The titanium mesh was ultrasonically cleaned with acetone, ethanol, and deionized water for 15 min to remove surface oil, and the polishing solution (HF:HNO 3 :H 2 O volume ratio 1: 4: 5) to clean and remove surface oxide, dry with cold wind as anode, graphite sheet as cathode, put into electrolyte (0.5wt%NH 4 F and 10wt% water ethylene glycol solution) in 40V constant voltage anodization for 1min; take it out and rinse it repeatedly with deionized water, after drying, apply the chloroiridic acid solution on the anodized titanium mesh, and then put it into the tube type Anodized IrO with corrosion resistance and high catalytic activity was obtained by calcination at 450°C for 2 hours 2 Coated titanium mesh, IrO 2 The load is 0.4mg / cm 2 .

[0041] Preparation of membrane electrode for hydrobromic acid electrolytic cell: Nafion 115 membrane is used to prepare membrane electrode, and the anode catalyst iridium black load is 2.7mg / cm 2 , the cathode catalyst Pt / C load ...

Embodiment 2

[0046] The titanium mesh was ultrasonically cleaned with acetone, ethanol, and deionized water for 15 min to remove surface oil, and the polishing solution (HF:HNO 3 :H 2 O volume ratio 1: 4: 5) to clean and remove surface oxide, dry with cold wind as anode, graphite sheet as cathode, put into electrolyte (0.5wt%NH 4 F and 10wt% water ethylene glycol solution) in 50V constant voltage anodization for 30s; after taking it out, rinse it repeatedly with deionized water, and after drying, apply the chloroiridic acid solution on the anodized titanium mesh, and then put it into the tube Anodized IrO with corrosion resistance and high catalytic activity was obtained by calcination at 450 °C for 2 h in a conventional furnace 2 Coated titanium mesh, IrO 2 The load is 0.5mg / cm 2 .

[0047] Preparation of membrane electrode for hydrobromic acid electrolytic cell: Nafion 115 membrane is used to prepare membrane electrode, and the anode catalyst iridium black load is 2.7mg / cm 2 , the c...

Embodiment 3

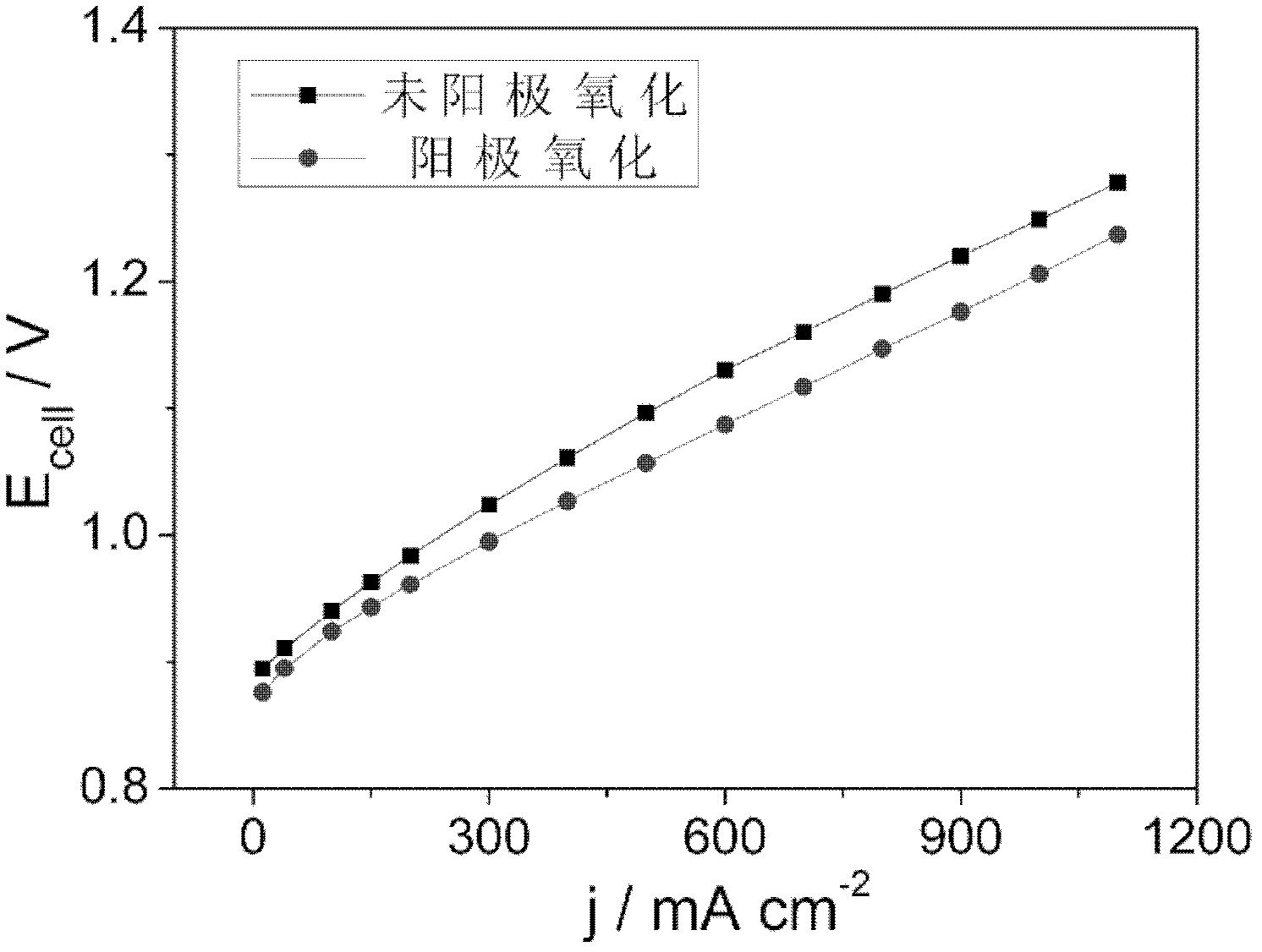

[0055] Treatment of titanium mesh, anodic oxidation process, loaded IrO 2 Process, preparation of membrane electrode, assembly and test of electrolytic cell are the same as in Example 1, after 40V anodic oxidation for 30s, load IrO 2 , the loading capacity is 0.4, 0.5mg / cm 2 . The electrolytic polarization curve at 70°C is as follows Figure 5 As can be seen from the figure, IrO 2 The electrolytic voltage of the electrolytic cell is significantly reduced after the loading capacity of the electrolytic cell is increased, and the greater the current density, the more obvious the advantage. It shows that the contact resistance between the diffusion layer, the catalytic layer and the bipolar plate decreases after the load is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com