Environment-friendly composite blocking remover composition for oil fields

A technology of composite plugging remover and composition, which is applied in the direction of drilling composition, chemical instruments and methods, etc., and can solve problems such as oil well equipment, pipeline corrosion, environmental protection problems, and incomplete treatment of acid-containing residual liquid. Achieve the effects of low corrosion, moderate concentration, convenient transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

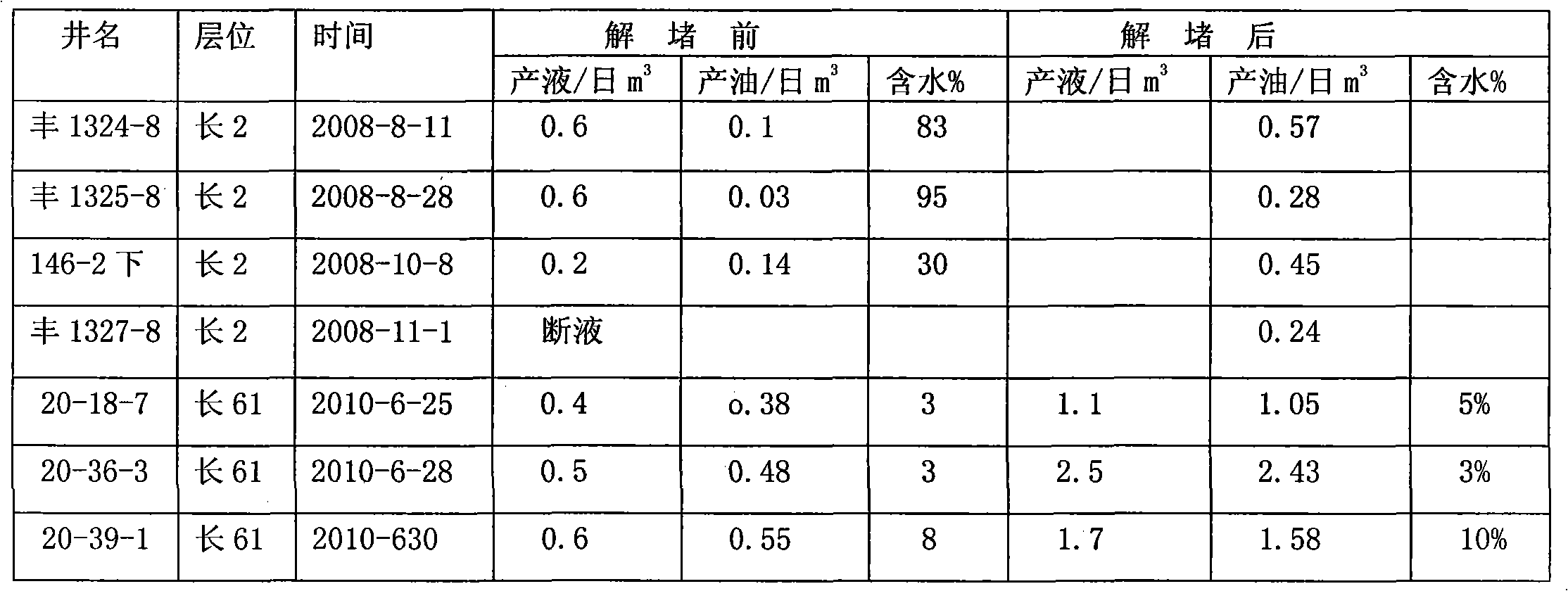

Examples

Embodiment 1

[0023] An environment-friendly oilfield composite plugging remover composition is characterized in that the composite plugging remover composition consists of 5 parts of surface active oil displacement agent, 7 parts of solid chlorine dioxide, and 8 parts of solid bactericidal activator according to the ratio of parts by mass. composition. Described surface-active oil displacement agent is by mass percentage, and wherein sodium octylbenzene sulfonate should account for 40% of total mass, polyoxyethylene ether should account for 15% of total mass, ethanol should account for 3% of total mass, water It should account for 48% of the total mass. Described solid chlorine dioxide is by mass percentage, wherein solid chlorate should account for 86% of total mass, carbonate should account for 4.4% carbonate of total mass, persalt should account for 9.6% of total mass. Described solid bactericidal type activator is by mass percentage, wherein bactericide should account for 53% of total...

Embodiment 2

[0026]An environment-friendly oilfield composite plugging remover composition is composed of 6 parts of surface-active oil-displacing agent, 10 parts of solid chlorine dioxide and 6 parts of solid bactericidal activator according to the ratio of parts by mass. The surface-active oil-displacing agent is composed of Percentage, wherein sodium octylbenzenesulfonate should account for 58% of the total mass, polyoxyethylene ether should account for 12% of the total mass, ethanol should account for 3.5% of the total mass, and water should account for 26.5% of the total mass. Described solid chlorine dioxide is by mass percentage, wherein solid chlorate should account for 86% of total mass, carbonate should account for 4.4% carbonate of total mass, persalt should account for 9.6% of total mass. The described solid bactericidal activator is by mass percentage, wherein the bactericide should account for 60% of the total mass, the activation accelerator should account for 8% of the total...

Embodiment 3

[0028] An environment-friendly oilfield composite plugging remover composition is composed of 8 parts of surface active oil displacement agent, 9 parts of solid chlorine dioxide, and 6 parts of solid bactericidal activator according to the ratio of parts by mass. The surface active oil displacement agent is composed of Mass percentage, wherein sodium octylbenzenesulfonate should account for 58% of the total mass, polyoxyethylene ether should account for 15% of the total mass, ethanol should account for 3.5% of the total mass, and the aqueous solution of effective content 50%, described Solid chlorine dioxide is by mass percentage, and wherein solid chlorate should account for 86% of gross mass, carbonate should account for 4.4% carbonate of gross mass, persalt should account for 9.6% of gross mass, described solid The bactericidal activator is based on mass percentage, wherein the bactericide should account for 74% of the total mass, the activation accelerator should account fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com