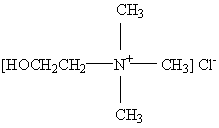

Choline-chloride-based chemical tinning solution and application method thereof

A technology of choline chloride and electroless tin plating, which is applied in the field of tin plating, can solve the problems of increasing waste liquid treatment costs and increasing costs, and achieve the effects of eliminating potential safety hazards, high wettability and solderability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 1L electroless tin plating solution

[0027] Get 500ml of choline chloride and deionized water according to the mixed solvent of molar ratio 1:8 configuration, add stannous chloride and be 40g, thiourea 150g, after dissolving, use choline chloride and water mixed solvent (molar ratio 1:8 ) to 1L. The electroless tin plating process using the electroless tin plating solution of the present invention is: first the copper substrate is placed in a 60°C degreasing solution (NaOH 10g / L, NaOH 2 CO 3 20g / L, Na 3 PO 4 12H 2 O 5g / L, OP-10 emulsifier 1g / L), washed with water after 1min; then placed in microetching solution at room temperature (H 2 SO 4 90ml / L), wash with water after 1min to remove the oxide film on the surface of the copper substrate; place the pretreated copper substrate in the electroless tin plating solution of the present invention at 40°C for 10min, then wash with water, and immediately remove the surface water traces,...

Embodiment 2

[0029] Embodiment 2 Preparation of 1L electroless tin plating solution

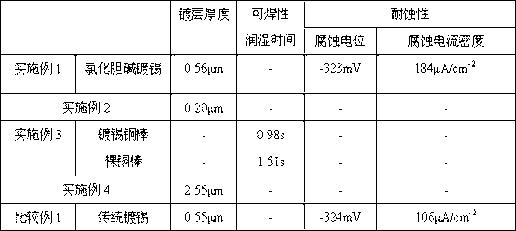

[0030] Get 500ml choline chloride and deionized water according to the mixed solvent of molar ratio 1:2 configuration, add stannous chloride and be 5g, thiourea 50g, after dissolving, use choline chloride and water mixed solvent (molar ratio 1:2 ) to 1L. See embodiment 1 for the electroless tin plating operation process. The results of coating thickness are listed in Table 1.

[0031]

Embodiment 3

[0032] Embodiment 3 Preparation of 1L electroless tin plating solution

[0033] Taking the test of its weldability as an example, comparing it with a copper rod of the same specification, and explaining its preparation method. The formula and operating process of electroless tin plating are shown in Example 1; in this example, a copper rod is used as the base material, and the results of the solderability of the coating are listed in Table 1.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com