Treatment of hydrocarbons containing acids

a technology of hydrocarbons and acids, applied in the field of hydrocarbons treatment, can solve the problems of slow reaction rate and difficulty in efficient treatment, and achieve the effect of minimizing or eliminating corrosion in down-stream plants and equipment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

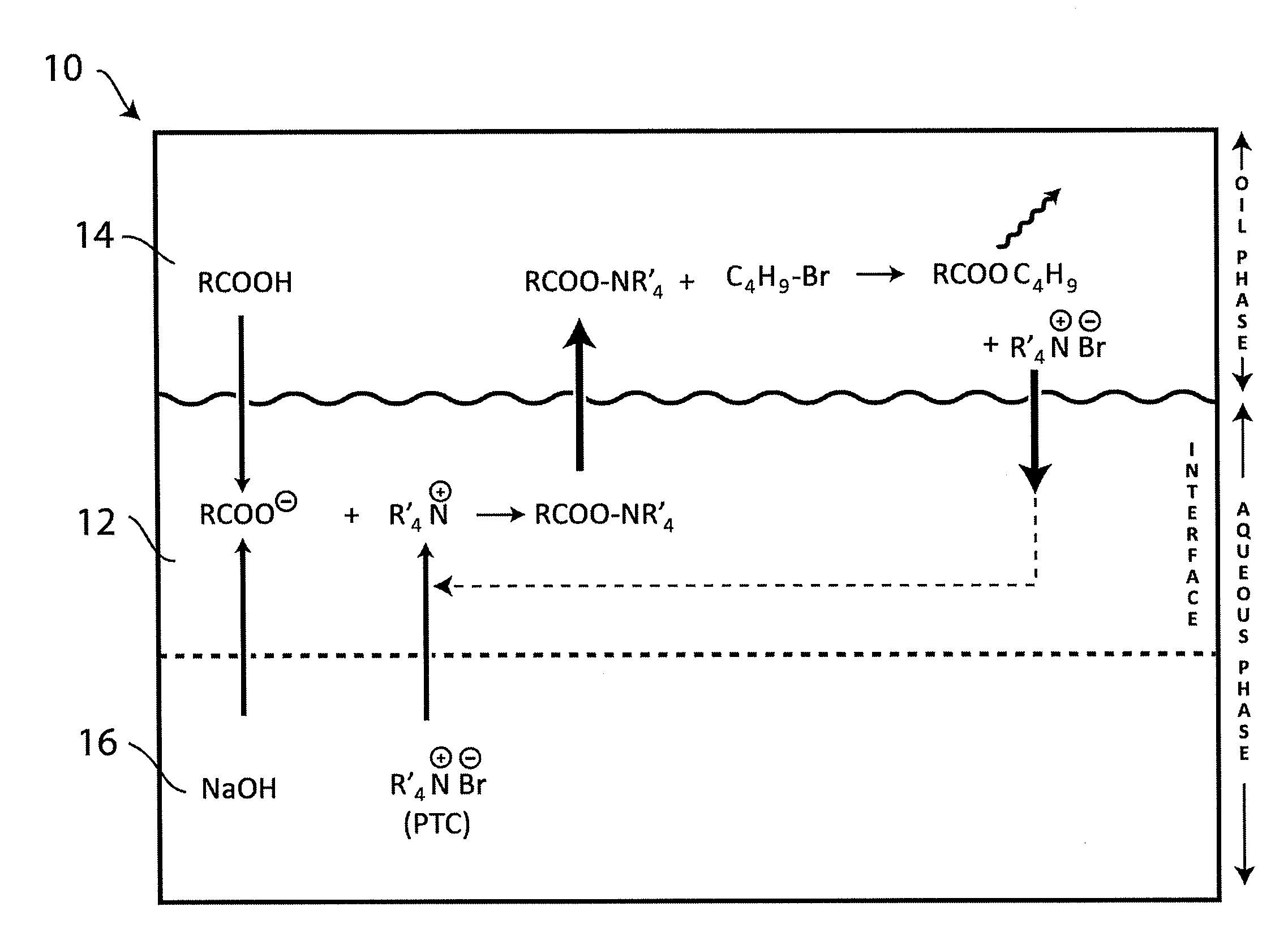

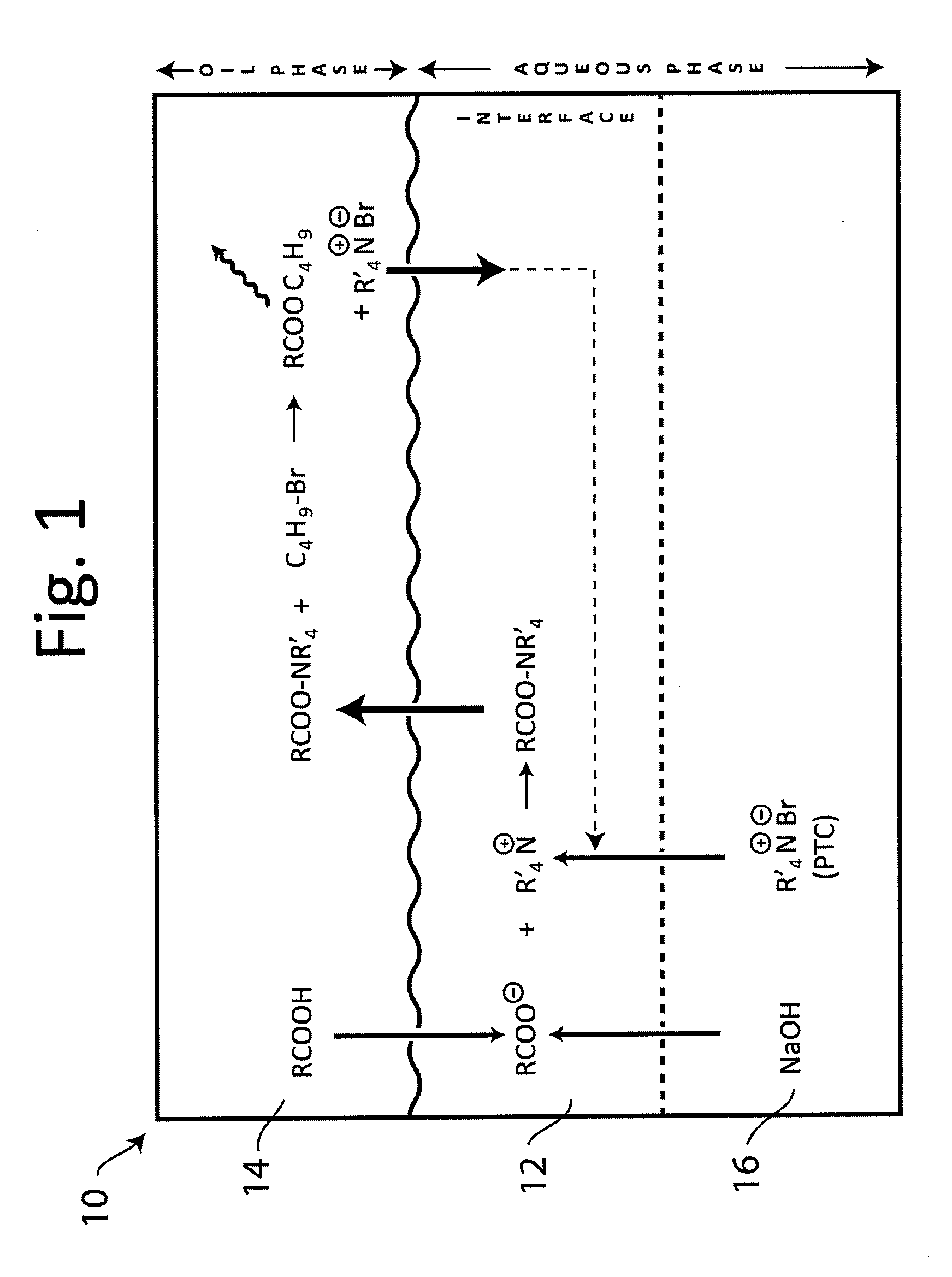

Method used

Image

Examples

examples

[0051]In the following Examples, all chemicals were purchased from Sigma Aldrich® and used without alteration. The properties of the HVGO used are listed in Table 1. All experiments were conducted following the procedure below:[0052]1. Bromobutane and heavy vacuum gas oil (HVGO) were added in a flask. The mixture was heated to 80° C. in an oil bath under stirring.[0053]2. PTC (tetrabutylammonium bromide) was completely dissolved in NaOH aqueous solution, and added to the flask prepared in 1.[0054]3. The above mixture was stirred at 80° C. for 4 hours.[0055]4. After reaction, the flask was quenched with cold water and the contents transferred into a centrifuge bottle.[0056]5. The water was separated from oil using an IECCR-6000® centrifuge (3800 rpm for 30 min).

[0057]The oil phase was analyzed for TAN, sulfur, nitrogen, and boiling range. The nitrogen and sulfur were analyzed according to ASTM D4629 (syringe / inlet oxidative combustion and chemiluminescence detection), and ASTM D4294 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com