Ionic liquid solution for preparing nano-porous silver and using method thereof

A nanoporous silver and ionic liquid solvent technology, which is applied in the field of liquid phase preparation of nanoporous metals, can solve the problems of operators, environmental hazards, and high equipment requirements, and achieve the effects of environmental friendliness, high purity, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Mix choline chloride and ethylene glycol at room temperature according to a molar ratio of 1:2, and heat up to 75° C. under magnetic stirring to obtain an ionic liquid composed of a mixture of choline chloride and ethylene glycol as a solvent. Measure 200 ml of the above-mentioned ionic liquid, and dissolve 0.287 g of AgCl in the above-mentioned ionic liquid to obtain an ionic liquid solution for preparing nanoporous silver.

[0018] The copper alloy (C194) with a thickness of 0.5mm was first degreased electrochemically, then washed with water, and dried.

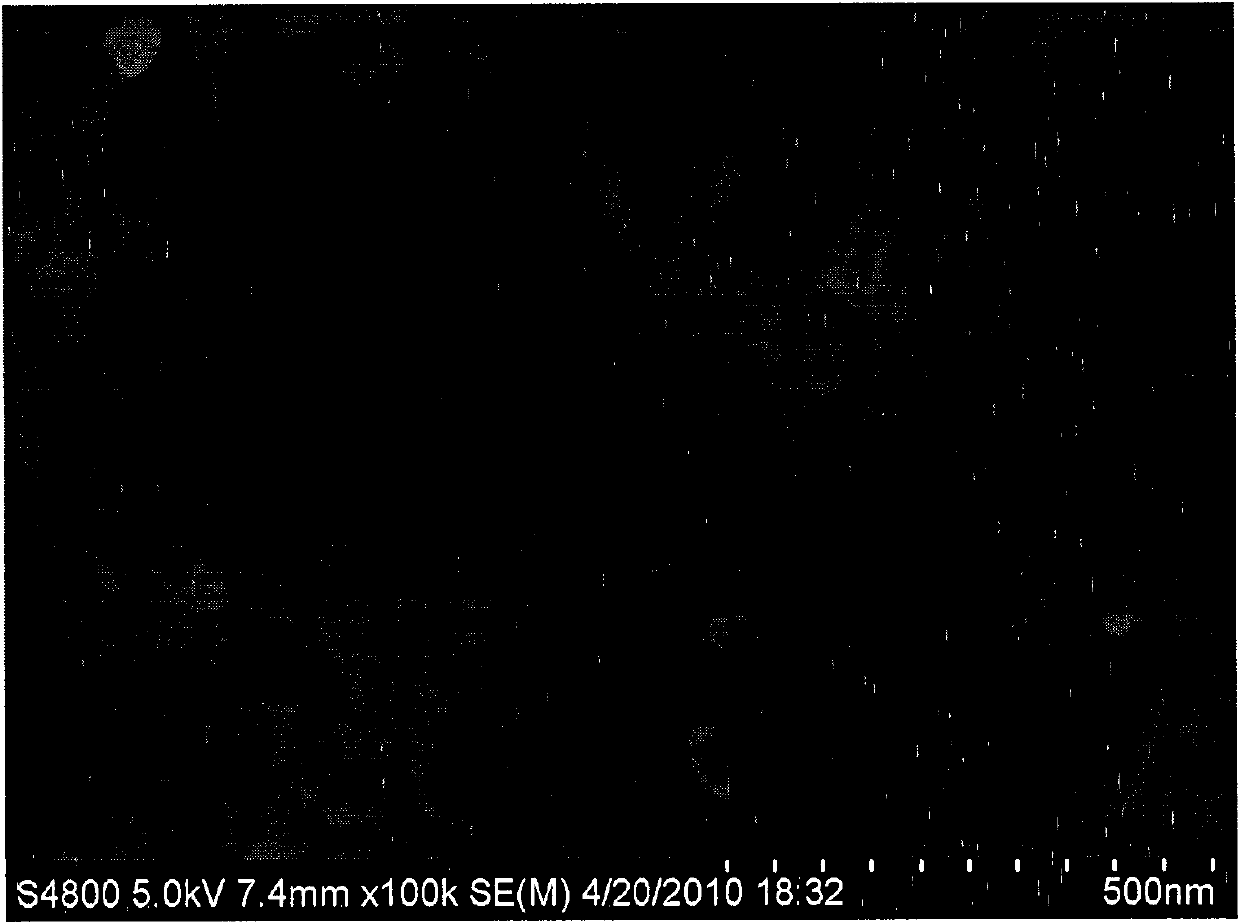

[0019] Immerse the cleaned copper alloy in the nanoporous silver ionic liquid solution prepared above, react at 50°C for 10 minutes, then wash with methanol and water, and dry to obtain pores with a diameter of 20-50nm on the surface of the copper alloy composed of nanoporous silver. Its scanning electron microscope pictures are as figure 1 shown.

Embodiment 2

[0021] Mix choline chloride and urea at room temperature according to a molar ratio of 1:2, and raise the temperature to 75° C. under magnetic stirring to obtain an ionic liquid composed of a mixture of choline chloride and urea. Measure 200 ml of the above-mentioned ionic liquid, and dissolve 0.287 g of AgCl in the above-mentioned ionic liquid to obtain an ionic liquid solution for preparing nanoporous silver.

[0022] The copper alloy (C194) with a thickness of 0.5mm was first degreased electrochemically, then washed with water, and dried.

[0023] Immerse the cleaned copper alloy in the ionic liquid solution prepared above, react at 25°C for 10 minutes, then wash with methanol and water, and dry to obtain nanoporous pores with diameters of 10-40nm on the surface of the copper alloy. silver.

Embodiment 3

[0025] Choline chloride and ethylene glycol were mixed at room temperature according to a molar ratio of 1:2, and the temperature was raised to 75° C. under magnetic stirring to obtain an ionic liquid composed of a mixture of choline chloride and ethylene glycol. Measure 200 ml of the above-mentioned ionic liquid, and dissolve 0.574 g of AgCl in the above-mentioned ionic liquid to obtain an ionic liquid solution for preparing nanoporous silver.

[0026] The copper alloy (C194) with a thickness of 0.5mm was first degreased electrochemically, then washed with water, and dried.

[0027] Immerse the cleaned copper alloy in the ionic liquid solution prepared above, react at 25°C for 20 minutes, then wash with methanol and water, and dry to obtain nanoporous pores with diameters of 10-40nm on the surface of the copper alloy. Silver, then placed in 1mol / L FeCl 3 The copper alloy is dissolved and removed in the aqueous solution to obtain nanoporous silver without matrix support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com