Method for extracting alumin from aluminous fly-ash and method for producing cement from fag end

A high-alumina fly ash and alumina technology, applied in the field of cement production, can solve the problems of high energy consumption, difficulty in realization, and low utilization rate of fly ash, achieve energy-saving calcination equipment, reduce production costs, and simplify calcination equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

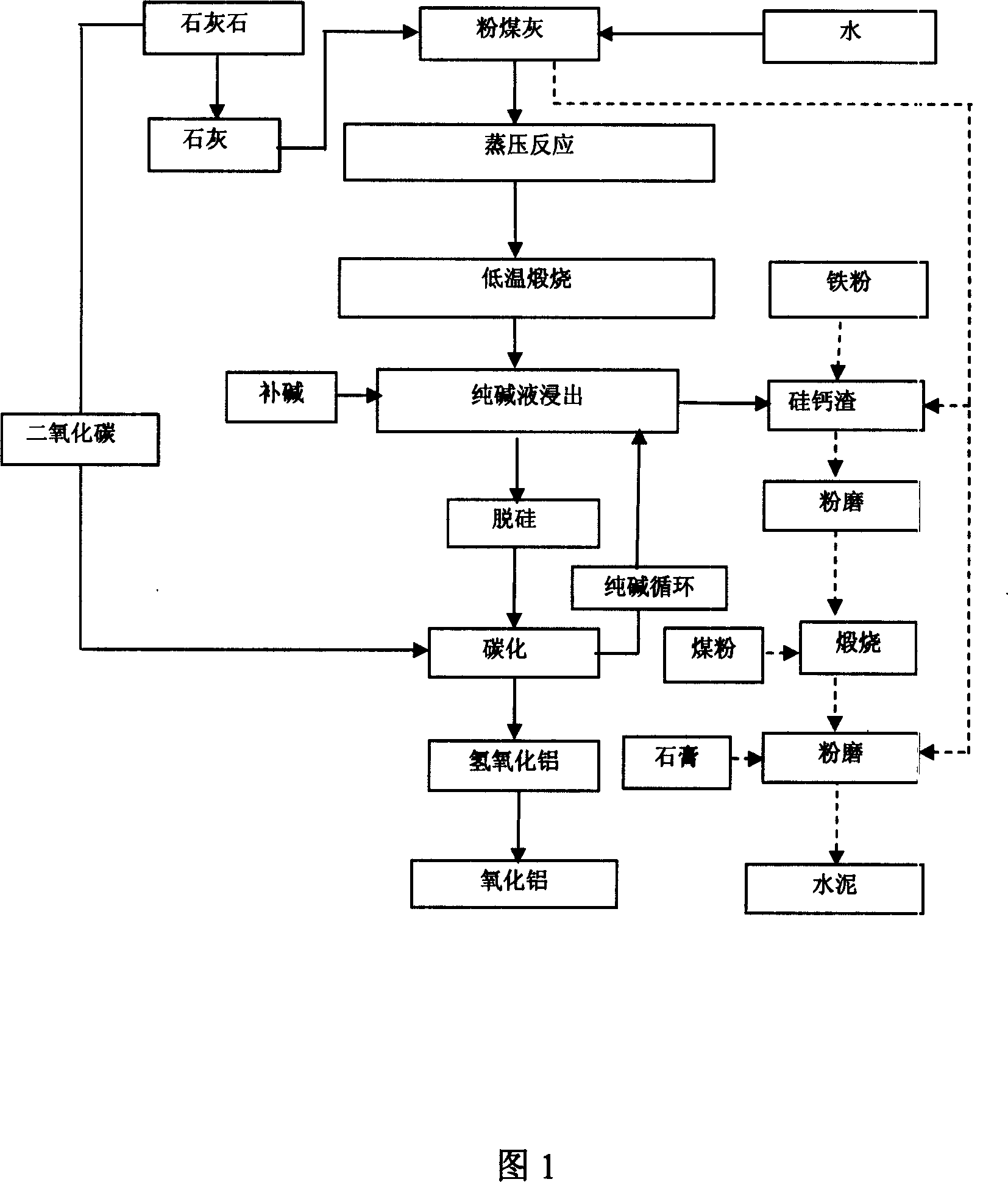

Image

Examples

Embodiment 1

[0034] raw material

[0035] Process ratio: fly ash / lime=1 / 2, adding water to solid-liquid ratio: 1:0.3, steaming at 180°C for 4 hours, calcining at 900°C for 4 hours, 8% sodium carbonate solution in accordance with the liquid-solid ratio of 5:1 After leaching at 80°C for 40 minutes, the leaching rate of alumina is 80%, and the content of silicon oxide in alumina is less than 0.3%, meeting the composition requirements of metallurgical grade alumina.

[0036] name

[0037] name

[0038] The results obtained from the above ingredients KH=0.89, SM=2.29, IM=1.31 all meet the requirements of wet kiln calcined cement. The 28-day compressive strength of the cement obtained according to the above ratio is greater than 52.5MPa, and the flexural resistance is greater than 7MPa, reaching the strength grade of No. 52.5 cement.

[0039] raw material

[0040] name

[0041] name

[0042] Among the above ingredients, KH=89, SM=1.94, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com