Method for comprehensively extracting aluminum and lithium from coal ash

A comprehensive extraction and fly ash technology, applied to chemical instruments and methods, lithium compounds, alkali metal compounds, etc., to achieve the effects of reducing raw material costs, simple process operation, and high comprehensive extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

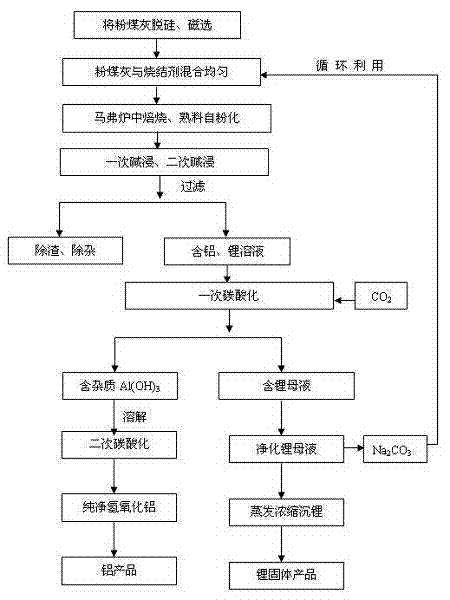

Image

Examples

Embodiment 1

[0033] In step (B), the mass ratio of fly ash to sintering agent is 1:0.5, wherein the sintering agent is sodium carbonate, the temperature of the muffle furnace is 950°C, the heating and roasting time is 60min, and the clinker is self-pulverized The operation process is: naturally cool down to 750°C, keep at constant temperature for 20 minutes to complete self-powdering; in step (C), the volume ratio of liquid and solid is 1:50, the mass fraction of sodium carbonate solution is 10%, and the temperature of the electric heating plate is 90°C, the heating time is 120min; in step (D), the volume ratio of liquid and solid is 1:50, the mass fraction of sodium carbonate solution is 10%, the temperature of the electric heating plate is 90°C, and the heating time is 60min; in step In (E), carbon dioxide gas is introduced into the solution, and the ventilation is stopped when the pH of the solution is 7; in step (F), the mother liquor containing lithium is evaporated and concentrated at...

Embodiment 2

[0036] In step (B), the mass ratio of fly ash to sintering agent is 1:1.5, wherein the sintering agent is sodium carbonate, the temperature of the muffle furnace is 850°C, the heating and roasting time is 90min, and the clinker is self-pulverized The operation process is as follows: naturally cool down to 650°C, keep at a constant temperature for 20 minutes to complete self-powdering; in step (C), the volume ratio of liquid and solid is 1:50, the mass fraction of sodium carbonate solution is 10%, and the temperature of the electric heating plate is 150°C, the heating time is 90min; in step (D), the volume ratio of liquid and solid is 1:50, the mass fraction of sodium carbonate solution is 10%, the temperature of the electric heating plate is 150°C, and the heating time is 60min; in step In (E), carbon dioxide gas is introduced into the solution, and the ventilation is stopped when the pH of the solution is 7; in step (F), the mother liquor containing lithium is evaporated and c...

Embodiment 3

[0039] In step (B), the mass ratio of fly ash to sintering agent is 1:3, wherein the sintering agent is sodium carbonate, the temperature of the muffle furnace is 650°C, the heating and roasting time is 90min, and the clinker is self-pulverized The operation process is as follows: naturally cool down to 450°C, keep at a constant temperature for 20 minutes to complete self-powdering; in step (C), the volume ratio of liquid and solid is 1:50, the mass fraction of sodium carbonate solution is 10%, and the temperature of the electric heating plate is 200°C, the heating time is 120min; in step (D), the volume ratio of liquid and solid is 1:50, the mass fraction of sodium carbonate solution is 10%, the temperature of the electric heating plate is 200°C, and the heating time is 60min; in step In (E), carbon dioxide gas is introduced into the solution, and the ventilation is stopped when the pH of the solution is 7; in step (F), the mother liquor containing lithium is evaporated and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com