Preparation method of alumina powder

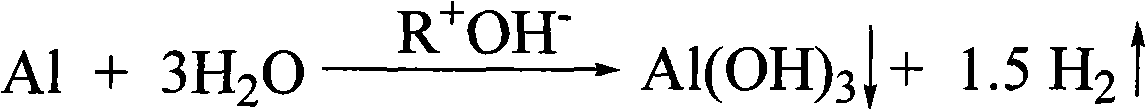

A technology of alumina powder and aluminum hydroxide, applied in the preparation of alumina/hydroxide, etc., can solve the problems of affecting the appearance and performance of alumina products, difficult to obtain high-purity products, and generating corrosive gases, etc. Environmentally friendly, low production process requirements and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

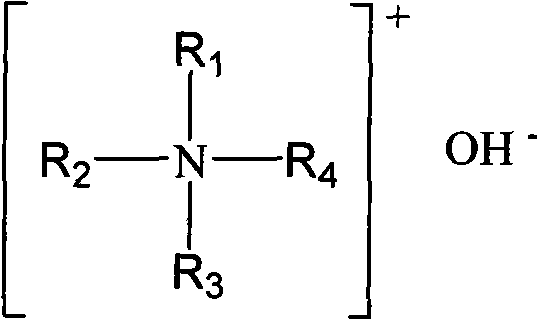

[0031] 6.5 grams of 99.7% aluminum flakes that weighed are put into the beaker of 500 milliliters, then add the tetrapropyl ammonium hydroxide (molecular formula (CH) of 100 milliliters 0.45mol / L 3 CH 2 CH 2 ) 4 N + Oh - ) aqueous solution, control the heating temperature in a water bath at 75°C, vibrate and stir for 5 hours, pass the reaction solution through a white steel sieve with a pore size of 150 microns, sieve out a small amount of unreacted aluminum chips, filter under reduced pressure and wash with 20 ml of deionized water The aluminum hydroxide filter cake is obtained by washing, and the filtrate is retained for recycling. After drying the filter cake at 120° C. for 2 hours, dry aluminum hydroxide was obtained, and the aluminum hydroxide was further calcined at 1080° C. for 6 hours to obtain 11.6 grams of α-phase alumina powder.

Embodiment 2

[0033] 4.5 grams of 99.9% metal aluminum foil that weighed is put into the beaker of 500 milliliters, then add the tetraethylammonium hydroxide (molecular formula (CH) of 100 milliliters 0.25mol / L 3 CH 2 ) 4 N + Oh -) aqueous solution, control the heating temperature of the water bath at 65°C, vibrate and stir for 8 hours, pass the reaction solution through a white steel sieve with a pore size of 120 microns, sieve out a small amount of unreacted aluminum chips, filter under reduced pressure and wash with 20 ml of deionized water The aluminum hydroxide filter cake is obtained by washing, and the filtrate is retained for recycling. The filter cake was dried under reduced pressure at 70°C and -0.08MPa for 1.5 hours to obtain dry aluminum hydroxide, which was further calcined at 500°C for 6 hours to obtain 8.3 grams of γ-phase alumina powder.

Embodiment 3

[0035] 7.0 grams of 99.99% metallic aluminum powder that weighed is put into the beaker of 500 milliliters, then add the benzyl trimethylammonium hydroxide (molecular formula C of 100 milliliters 1.5mol / L) 6 h 5 CH 2 (CH 3 ) 3 N + Oh - ) aqueous solution, control the heating temperature in a water bath at 70°C, vibrate and stir for 2 hours, pass the reaction solution through a white steel sieve with a pore size of 120 microns, sieve out a small amount of unreacted aluminum chips, filter under reduced pressure and wash with 20 ml of deionized water The aluminum hydroxide filter cake is obtained by washing, and the filtrate is retained for recycling. After the filter cake was dried at 120°C for 2 hours, dry aluminum hydroxide was obtained, and the aluminum hydroxide was further calcined at 600°C for 6 hours to obtain 13.1 g of γ-phase alumina powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com