Method for preparing spherical alumina particles by alginic acid auxiliary forming method

A spherical alumina, auxiliary molding technology, applied in the preparation of alumina/hydroxide, etc., can solve the problems of high energy consumption, slow curing speed, environmental pollution, etc. of the oil column molding method, and achieve high production efficiency, convenient operation, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing spherical alumina particles by an alginic acid-assisted molding method, comprising the steps of:

[0028] (1) Take 50g of pseudo-boehmite, add 70ml of water to disperse, then add 70ml of sodium alginate aqueous solution with a mass concentration of 3%, and stir to form a sodium alginate-pseudo-boehmite suspension;

[0029] (2) Drop the sodium alginate-pseudoboehmite suspension into an aqueous solution of aluminum nitrate with a concentration of 0.3M and pH=3, and the gel will form a composite of alginate-pseudoboehmite gel in 40 minutes. small ball;

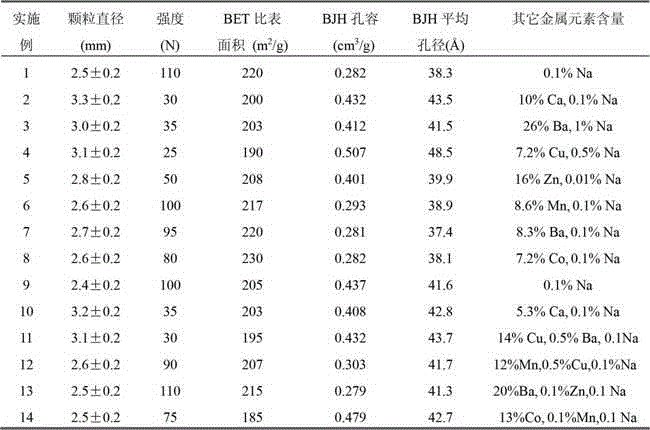

[0030] (3) After the alginic acid-pseudoboehmite glue composite pellets were washed with water and dried, they were calcined at 600° C. for 4 hours to obtain spherical alumina particles. The particle properties are listed in Table 1.

Embodiment 2

[0032] A method for preparing spherical alumina particles by an alginic acid-assisted molding method, comprising the steps of:

[0033] (1) Take 20g of pseudo-boehmite, add 50ml of water to disperse, then add 50ml of sodium alginate aqueous solution with a mass concentration of 4%, and stir to form a sodium alginate-pseudo-boehmite suspension;

[0034] (2) Drop the sodium alginate-pseudoboehmite suspension into an aqueous solution of calcium nitrate with a concentration of 1.0M and pH=2, and form a composite of alginate-pseudoboehmite gel after 30 minutes small ball;

[0035] (3) After the alginic acid-pseudoboehmite glue composite pellets were washed with water and dried, they were calcined at 500° C. for 8 hours to obtain spherical alumina particles. The particle properties are listed in Table 1.

Embodiment 3

[0037] A method for preparing spherical alumina particles by an alginic acid-assisted molding method, comprising the steps of:

[0038] (1) Take 70g of pseudo-boehmite, add 100ml of water to disperse, then add 100ml of sodium alginate aqueous solution with a mass concentration of 2%, and stir to form a sodium alginate-pseudoboehmite suspension;

[0039] (2) Drop the sodium alginate-pseudoboehmite suspension into an aqueous solution of barium nitrate with a concentration of 0.5M and pH=2, and the gel will form a composite of alginate-pseudoboehmite gel in 60 minutes small ball;

[0040] (3) After the alginic acid-pseudoboehmite glue composite pellets were washed with water and dried, they were calcined at 800° C. for 5 hours to obtain spherical alumina particles. The particle properties are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com