Method for producing alumina and white carbon black by utilizing red mud and flyash

A technology for fly ash and alumina, which is applied in the preparation of alumina/hydroxide, silica, silica, etc., can solve the problem of no alumina and silica, and achieve low production cost and simple process flow. , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

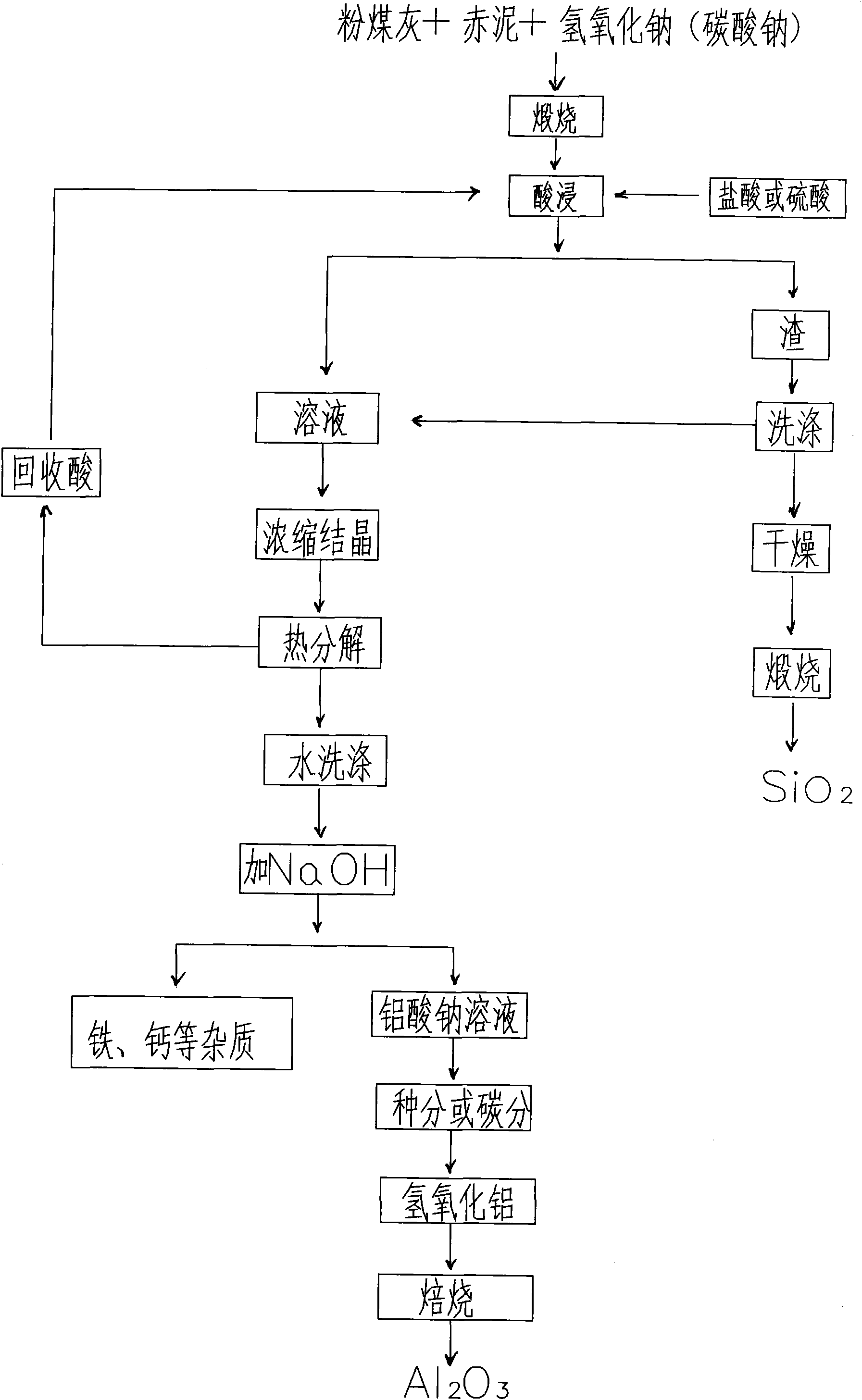

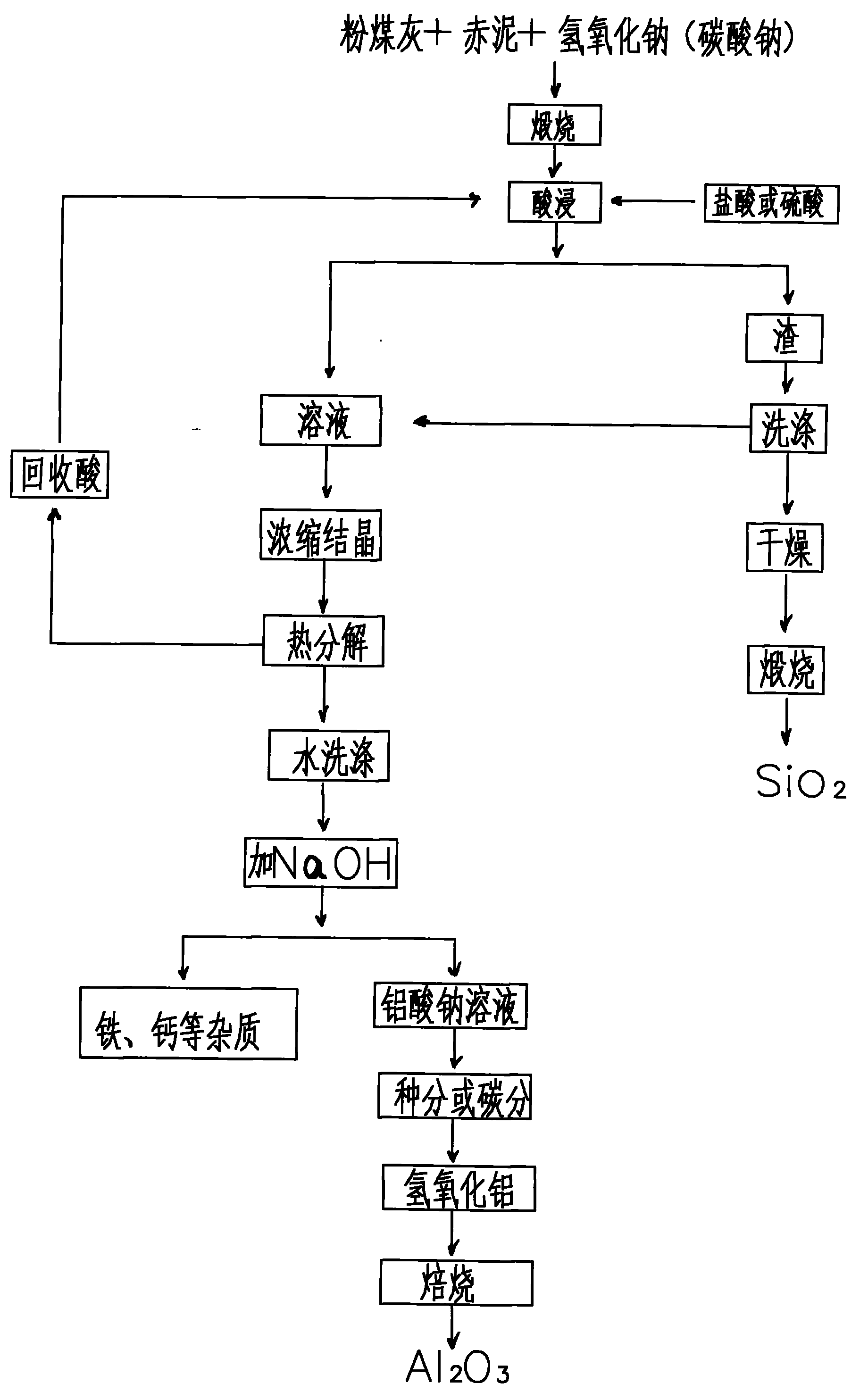

Method used

Image

Examples

Embodiment 1

[0025] Take 5g of fly ash, the main chemical composition of fly ash: Al 2 o 3 : 21.6%, SiO 2 : 47.12%, Fe 2 o 3 : 4.82%, CaO: 5.5%, red mud 6.7g, main chemical composition of red mud: Al 2 o 3 : 21.6%, SiO 2 : 15.96%, Fe 2 o 3 : 14.92%, CaO: 23.00%, Na 2 O: 8.0%. Add 0.5g of NaOH and calcining at 800°C for 60 minutes. Leach with hydrochloric acid, the concentration is 10%, and the leaching time is 30 minutes, and the solution and residue are obtained by filtration. The main component of the residue is SiO 2 , washed with water, filtered and calcined to obtain white carbon black. The acid leaching solution and the water washing solution of the acid residue are concentrated and crystallized. Thermally decompose the crystalline material, the heating temperature is 500°C, and at the same time recover hydrochloric acid for recycling. The thermally decomposed products are washed with water to recover sodium chloride and calcium chloride, then add NaOH to adjust the pH v...

Embodiment 2

[0027] The components of fly ash and red mud used are the same as those in Example 1. Take 5 g of fly ash and 13 g of red mud, add 1.0 g of NaOH, and calcining at 790° C. for 25 minutes. When leaching with hydrochloric acid, the concentration is 20%, the leaching time is 30 minutes, and the solution and residue are obtained by filtration. The main component of the residue is SiO 2 , washed, filtered and calcined to obtain white carbon black. The acid leaching solution and the water washing solution of the acid residue are concentrated and crystallized. Thermally decompose the crystalline material, the heating temperature is 500°C, and at the same time recover hydrochloric acid for recycling. The thermally decomposed product is washed with water, sodium chloride and calcium chloride are recovered, and NaOH is added to adjust the pH value to remove iron, calcium, magnesium and other impurities to obtain a pure sodium aluminate solution, which is decomposed by adding aluminum h...

Embodiment 3

[0029] Take 5g of fly ash, the main chemical composition of fly ash: Al 2 o 3 : 25.9%, SiO 2 : 46.15%, Fe 2 o 3 : 6.85%, CaO: 8.0%, red mud 10g, main chemical composition of red mud: Al 2 o 3 : 23.15%, SiO 2 : 18.90%, Fe 2 o 3 : 10.15%, CaO: 21.55%, Na 2 O: 9.1%, add NaOH 0.5g, calcining temperature 800°C, time 120 minutes. When leaching with hydrochloric acid, the concentration is 23%, the leaching time is 45 minutes, and the solution and residue are obtained by filtration. The main component of the residue is SiO 2 , washed, filtered, and calcined to obtain 4.0 g of white carbon black. The acid leaching solution and the water washing solution of the acid residue are concentrated and crystallized. Thermally decompose the crystalline material, the heating temperature is 500°C, and at the same time recover hydrochloric acid for recycling. The thermally decomposed product is washed with water to recover sodium chloride and calcium chloride, and then NaOH is added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com