Technical method for comprehensively extracting aluminum and lithium from coal ash through acid process

A technology of comprehensive extraction and process method, which is applied in the field of comprehensive extraction of aluminum and lithium from fly ash by acid treatment, and achieves the effects of large comprehensive extraction rate, reduction of raw material cost, and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

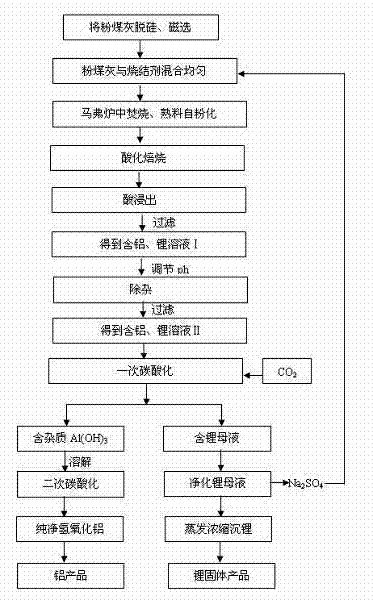

Image

Examples

Embodiment 1

[0035] In step (B), the mass ratio of fly ash to sintering agent is 1:1, wherein the sintering agent is a mixture of potassium sulfate and sodium sulfate with a mass ratio of 0.7:0.3, and the temperature of the muffle furnace is 1050°C. The incineration time is 60 minutes, and the operation process of clinker self-powdering is as follows: natural cooling to 850°C, constant temperature for 20 minutes to complete self-powdering; in step (C), the volume ratio of liquid and solid is 2:1, the temperature of the electric heating plate 200°C; in step (D), the volume ratio of liquid to solid is 2:1, deionized water is 100ml, the temperature of the water bath is 60°C, and the water bath is heated for 40 minutes; in step (F), during the carbonation treatment, control When ventilating, the initial temperature of the solution is 75°C, the rate of carbon dioxide ventilating is 3.5L / min, and the ventilating is stopped when the pH of the solution is 7; in step (G), the lithium-containing moth...

Embodiment 2

[0038] In step (B), the mass ratio of fly ash to sintering agent is 1:1.5, wherein the sintering agent is a mixture of potassium sulfate and sodium sulfate with a mass ratio of 1:0.5, and the temperature of the muffle furnace is 950°C. The incineration time is 90 minutes, and the operation process of clinker self-powdering is as follows: naturally cool down to 750°C, and keep at a constant temperature for 20 minutes to complete self-powdering; in step (C), the volume ratio of liquid and solid is 2:1, and the temperature of the electric heating plate 200°C; in step (D), the volume ratio of liquid to solid is 2:1, deionized water is 100ml, the temperature of the water bath is 80°C, and the water bath is heated for 20 minutes; in step (F), during the carbonation treatment, control When ventilating, the initial temperature of the solution is 75°C, the rate of carbon dioxide ventilating is 3.5L / min, and the ventilating is stopped when the pH of the solution is 7; in step (G), the li...

Embodiment 3

[0041] In step (B), the mass ratio of fly ash to sintering agent is 1:2, wherein the sintering agent is a mixture of potassium sulfate and sodium sulfate with a mass ratio of 1:1, and the temperature of the muffle furnace is 650°C. The incineration time is 120min, and the operation process of clinker self-powdering is as follows: natural cooling to 450°C, constant temperature for 20min to complete self-powdering; in step (C), the volume ratio of liquid and solid is 2:1, the temperature of the electric heating plate 200°C; in step (D), the volume ratio of liquid to solid is 2:1, deionized water is 100ml, the temperature of the water bath is 40°C, and the water bath is heated for 60 minutes; in step (F), during the carbonation treatment, control When ventilating, the initial temperature of the solution is 75°C, the rate of carbon dioxide ventilating is 3.5L / min, and the ventilating is stopped when the pH of the solution is 7; in step (G), the mother liquor containing lithium is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com