Illite mesoporous composite material and supported catalyst, preparation method and application thereof, and preparation method of cyclohexanone glycerol ketal

A technology of supported catalysts and composite materials, applied in the direction of organic compound/hydride/coordination complex catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problem of low conversion rate of reaction raw materials, achieve less side reactions, High reaction raw material conversion rate, simple after-treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

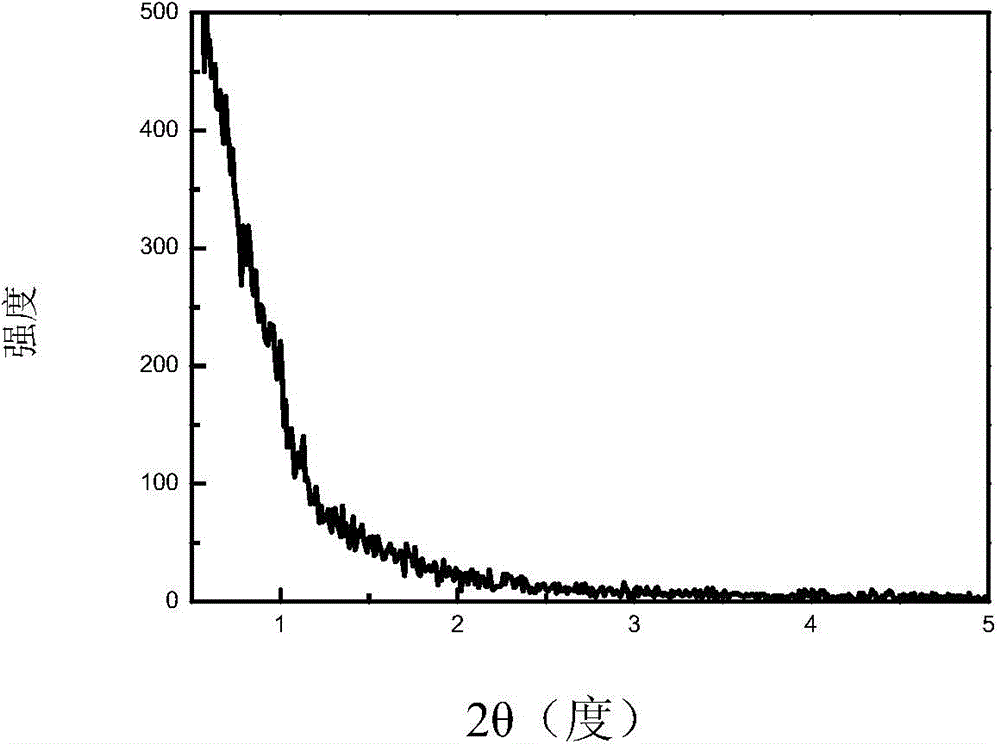

[0049] In step (1), "providing a mesoporous molecular sieve material with a three-dimensional cubic pore structure" can be directly weighed or selected a product of a mesoporous molecular sieve material with a three-dimensional cubic pore structure, or can be prepared with a three-dimensional cubic pore structure. Mesoporous molecular sieve materials. The preparation method of the mesoporous molecular sieve material with a three-dimensional cubic channel structure can be implemented according to a conventional method, for example, the preparation method can include: preparing a filter cake of a mesoporous molecular sieve material with a three-dimensional cubic channel structure according to the above method, and then The obtained filter cake is dried, and the templating agent in the product obtained after drying is removed. The conditions for removing the template agent may include: a temperature of 300-600° C. and a time of 10-80 hours.

[0050] The process of preparing the ...

Embodiment 1

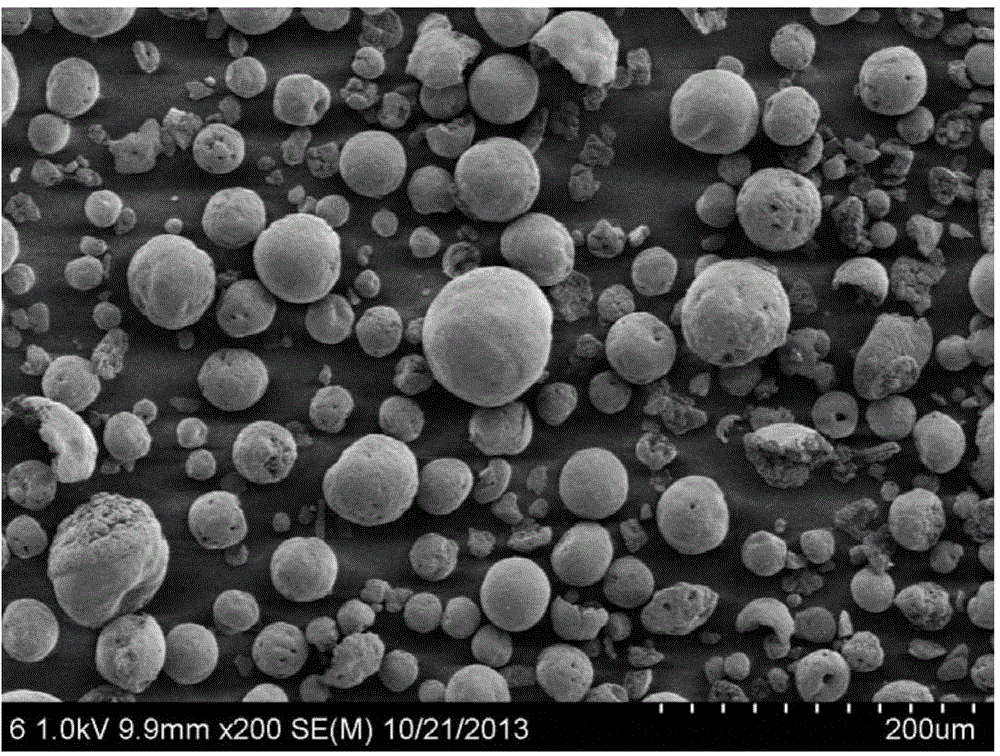

[0091] This example is used to illustrate the spherical illite mesoporous composite material and supported catalyst of the present invention and their preparation methods.

[0092] (1) Preparation of spherical illite mesoporous composites

[0093] Dissolve 6g (0.001mol) of triblock copolymer surfactant P123 in 10ml of hydrochloric acid aqueous solution with a pH value of 4 and 220ml of deionized aqueous solution, stir for 4h until P123 dissolves to form a transparent solution, and then add it to the transparent solution Add 6g (0.08mol) of n-butanol and stir for 1h, then place it in a water bath at 40°C, slowly add 12.9g (0.062mol) of tetraethyl orthosilicate into the solution, and keep the temperature at about 40°C. Stir for 24 hours at a pH value of 4.5, then hydrothermally treat at 100°C for 24 hours, then filter and wash with deionized water for 4 times, and then suction filter to obtain filter cake X1 of mesoporous molecular sieve material with three-dimensional cubic por...

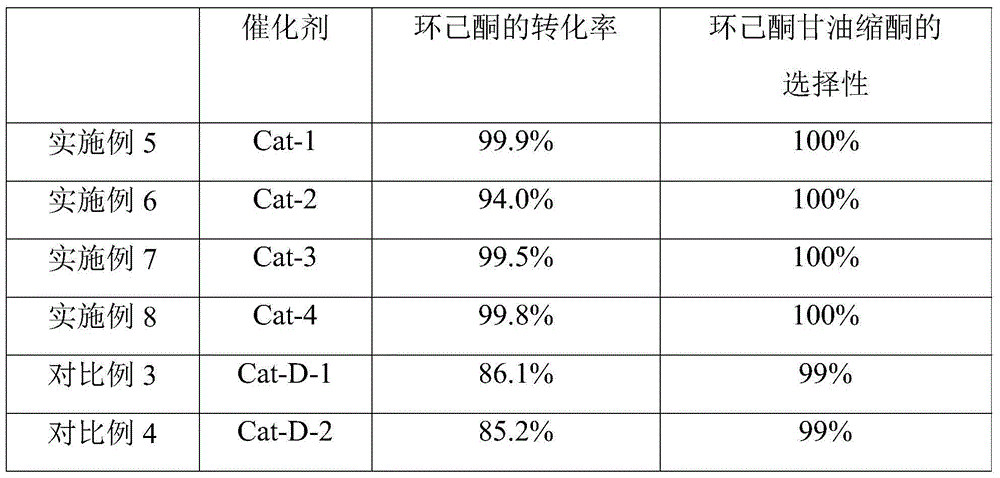

Embodiment 2

[0111] This example is used to illustrate the spherical illite mesoporous composite material and supported catalyst of the present invention and their preparation methods.

[0112] The spherical illite mesoporous composite material and the supported catalyst were prepared according to the method of Example 1. The difference was that there was no spray-drying step in the process of preparing the supported catalyst, but only the benzenesulfonic acid was loaded on the spherical illite by the method of impregnation. On the illite mesoporous composite material, the supported catalyst Cat-2 was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com