Illite loaded nanocarbon compound adsorbing material and preparation method thereof

A composite adsorption material and illite technology, which is applied in the field of illite-loaded nano-carbon composite adsorption material and its preparation, can solve the problems of unsafe operating environment, expensive raw materials, harsh reaction conditions, etc., and achieves simple preparation process and cheap raw materials. Easy availability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The specific implementation steps are as follows:

[0020] (1) Take 2.5g of illite and 2.5g of glucose and disperse in 50mL water for 30min to prepare a mixed suspension;

[0021] (2) Transfer the mixed suspension obtained in step (1) into an autoclave, and conduct a hydrothermal reaction at 160° C. for 24 hours;

[0022] (3) washing and filtering the reaction product obtained in step (2) with ethanol and water, and drying at 60° C. for 12 hours;

[0023] (4) Grinding the dried product obtained in step (3) until 97% passes through a 200-mesh sieve to obtain illite-loaded nano-carbon composite adsorption material.

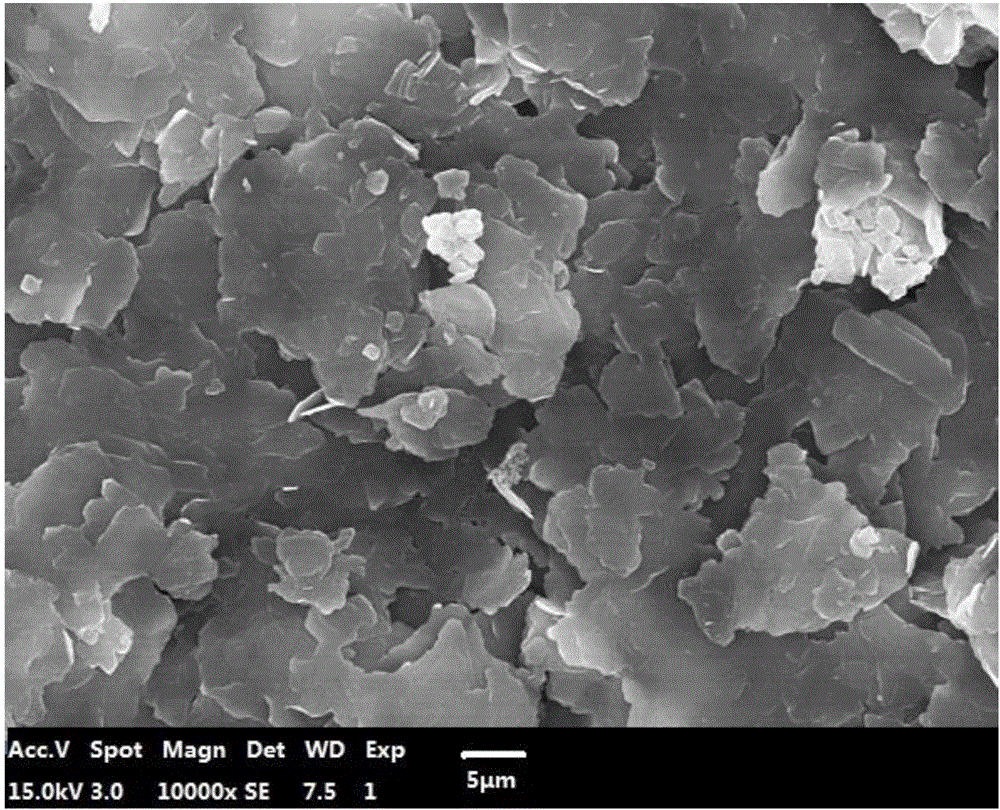

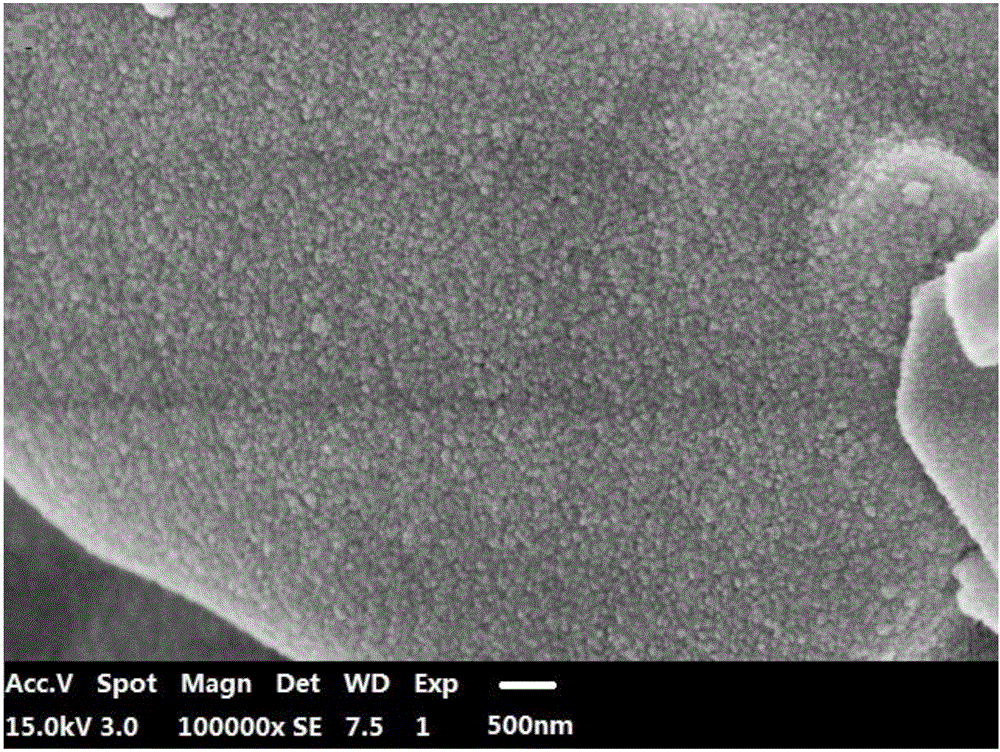

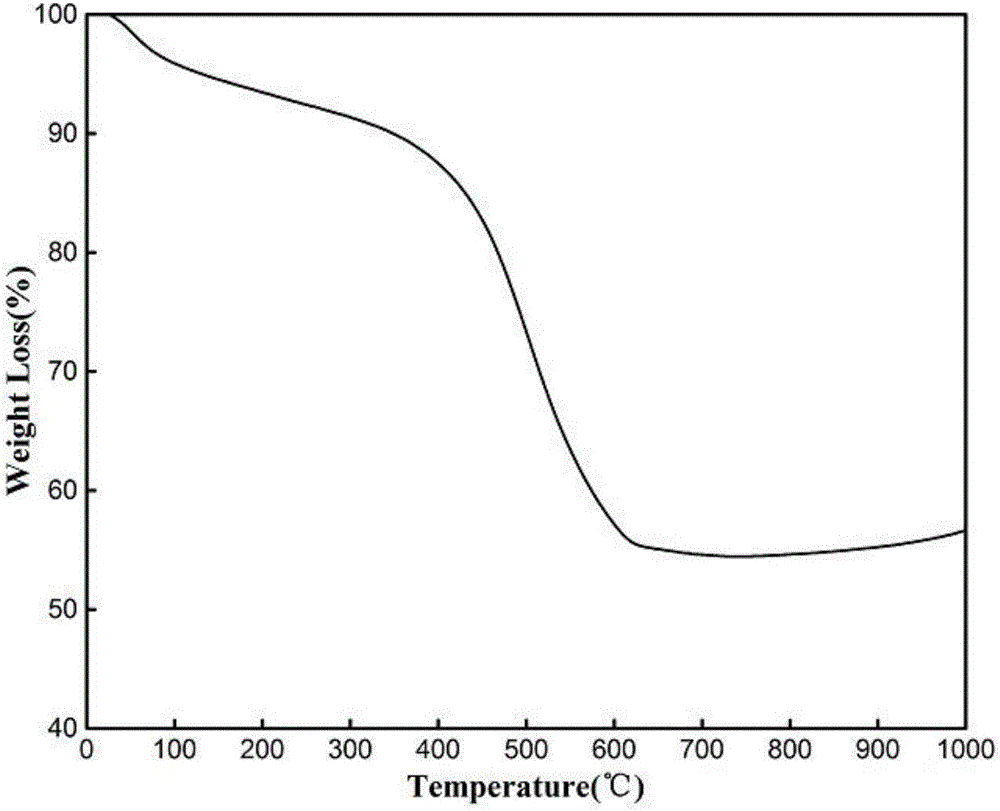

[0024] The SEM and TG figures of the illite-loaded nano-carbon composite adsorption material prepared in Example 1 are shown in the appendix figure 2 and 3 . Depend on figure 2 It can be seen that the illite sheet surface is evenly loaded with nano-carbon particles, and its average particle size is 30-50nm; image 3 It can be seen that the loading amo...

Embodiment 2

[0026] The steps are the same as those in Example 1, except that the amount of sucrose added in step (1) is 5.0 g, dispersed with 60 mL of water; the reaction temperature in step (2) is 180° C., and the reaction time is 20 h;

Embodiment 3

[0028] The steps are the same as those in Example 1, except that the amount of starch added in step (1) is 7.5 g, dispersed with 70 mL of water; the reaction temperature in step (2) is 200 ° C, and the reaction time is 16 h;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com