Illite-based composite titanium dioxide and preparation method thereof

A composite titanium dioxide and illite technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of insufficient covering power, low weather resistance, and insufficient bonding, and achieve strong covering power. , low cost, low oil absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

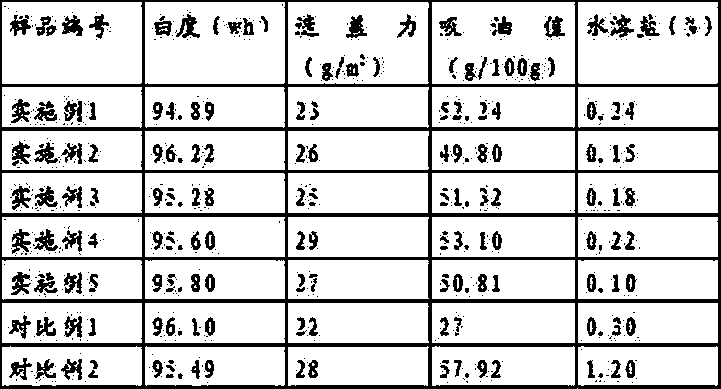

Examples

Embodiment 1

[0034] Weigh 60g of illite with a particle size of 1250 mesh and a Hunter whiteness of 86, add 600g of water to make a 100g / L slurry, add 15g of sodium hexametaphosphate solution with a mass fraction of 20%, and stir. Keep stirring, add 210ml of 100g / L titanium sulfate solution, adjust the pH value of the slurry to 1.0, and make a composite titanium dioxide slurry with nanoscale titanium dioxide deposited on the surface.

[0035] Beat and wash the deposited composite titanium dioxide slurry with deionized water at 40-50°C, and filter to obtain a filter cake;

[0036] The filter cake obtained by washing and filtering was calcined at 700 degrees for 6 hours, and then pulverized after calcining to obtain illite-based composite titanium dioxide.

Embodiment 2

[0038] Weigh 70g of illite with a particle size of 2000 mesh and a Hunter whiteness of 89, add 350g of water to make a 200g / L slurry, add 1.75g of sodium silicate solution with a mass fraction of 20%, and stir. Keep stirring, add 68ml of 200g / L titanium tetrachloride solution, adjust the pH value of the slurry to 2.0, and make a composite titanium dioxide slurry with nanoscale titanium dioxide deposited on the surface.

[0039] Beat and wash the deposited composite titanium dioxide slurry with deionized water at 40-50°C, and filter to obtain a filter cake;

[0040]The washed filter cake obtained by washing and filtering is calcined at 800 degrees for 8 hours, and then pulverized after calcining to obtain illite-based composite titanium dioxide.

Embodiment 3

[0042] Weigh 65g of illite with a particle size of 1500 mesh and a Hunter whiteness of 87, add 130g of water to make a 500g / L slurry, add 6.5g of sodium hexametaphosphate solution with a mass fraction of 20%, and stir. Keep stirring, add 220ml of 100g / L titanyl sulfate solution, adjust the pH value of the slurry to 3.0, and make a composite titanium dioxide slurry with nanoscale titanium dioxide deposited on the surface.

[0043] Beat and wash the deposited composite titanium dioxide slurry with deionized water at 40-50°C, and filter to obtain a filter cake;

[0044] The filter cake obtained by washing and filtering was calcined at 700°C for 10 hours, and then pulverized after calcining to obtain illite-based composite titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com