Preparation method of TiO2/illite inorganic UV-blocking agent

A UV shielding agent and illite technology, which is applied in the preparation field of TiO2/illite new inorganic ultraviolet shielding agent, can solve the problems of poor dispersion performance of nano-TiO2, limited application and research of illite, and reduced UV shielding performance. UV shielding performance, lower production cost, good dispersion in water phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

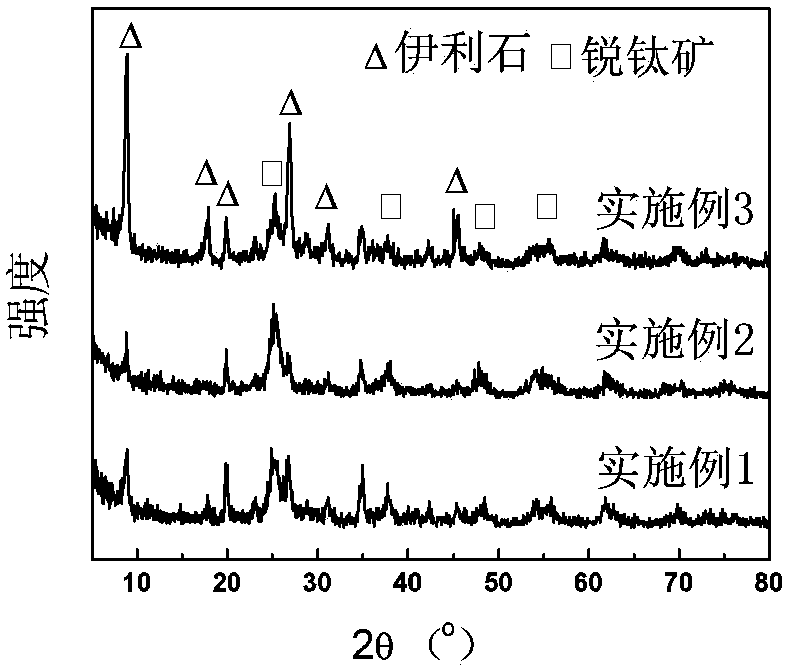

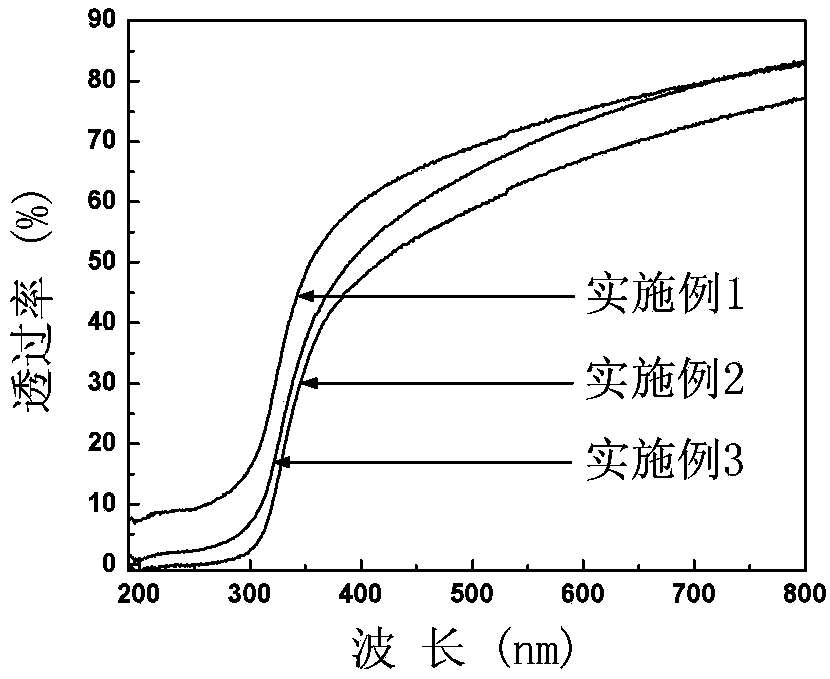

Embodiment 1

[0024]Take 2g of the purified Jilin Antu illite powder, add 100mL of water, ultrasonically treat for 30min, then magnetically stir for 12h, then take 2.57g of titanium sulfate, add 42.86ml of water, stir well, slowly add to the illite dispersion, and then Stir magnetically for 2 h to make it fully mixed. Then use ammonia water as a precipitating agent to adjust the pH of the dispersion to 4.0. After continuing magnetic stirring for 2 hours, transfer the slurry to a polytetrafluoroethylene stainless steel hydrothermal reaction kettle and keep it warm at 180°C for 12 hours. drying under the hood to obtain TiO 2 / Illite composite powder UV shielding agent. The UV-Vis ultraviolet transmittance test of this sample shows that it can shield 50% of UVA and nearly 92% of UVB and UVC. Add water to the above sample to prepare a 20 g / l suspension, add 0.05 g of hydroxypropyl methylcellulose as a surfactant, and stir magnetically for 12 hours to obtain an anti-ultraviolet finishing sol...

Embodiment 2

[0026] Take 2g of Jilin Antu illite powder, add 100mL of water, ultrasonically treat for 30min, then magnetically stir for 12h, then take 6g of titanium sulfate, add 100mL of water, stir well and slowly add to the illite dispersion, magnetically stir for 2h to make it fully well mixed. Then use ammonia water as a precipitating agent to adjust the pH of the dispersion to 4.0. After continuing magnetic stirring for 2 hours, transfer the slurry to a polytetrafluoroethylene stainless steel hydrothermal reaction kettle and keep it warm at 180°C for 12 hours. After cooling down, perform solid-liquid separation and wash the precipitate, and dry the precipitate at 80°C , that is, the TiO 2 / Illite composite powder UV shielding agent. The UV-Vis ultraviolet transmittance test of this sample shows that it can shield 60% of UVA and close to 100% of UVB and UVC. Add water to the above sample to prepare a 20g / L suspension, add an appropriate amount of cetyltrimethylammonium bromide as ...

Embodiment 3

[0028] Take 1g of Jilin Antu illite powder, add 100mL of water, ultrasonically treat for 30min, then magnetically stir for 12h, then take 3g of titanium sulfate, add 100mL of water, stir well and slowly add to the illite dispersion, magnetically stir for 2h to make it fully well mixed. Then use ammonia water as a precipitating agent to adjust the pH of the dispersion to 6.0. After continuing magnetic stirring for 2 hours, transfer the slurry to a polytetrafluoroethylene stainless steel hydrothermal reaction kettle, and keep it warm at 160°C for 12 hours. After cooling down, perform solid-liquid separation and wash the precipitate, and dry the precipitate at 80°C. TiO 2 / Illite composite powder UV shielding agent. The UV-Vis ultraviolet transmittance test was carried out on the sample, and the results showed that it could shield 50% of UVA, 90% of UVB and 95% of UVC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com