High water absorption composite material and its preparation method

A composite material and high water absorption technology, applied in the field of high water absorption composite material and its preparation, can solve the problems of high cost, difficult large-scale application, poor environmental compatibility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

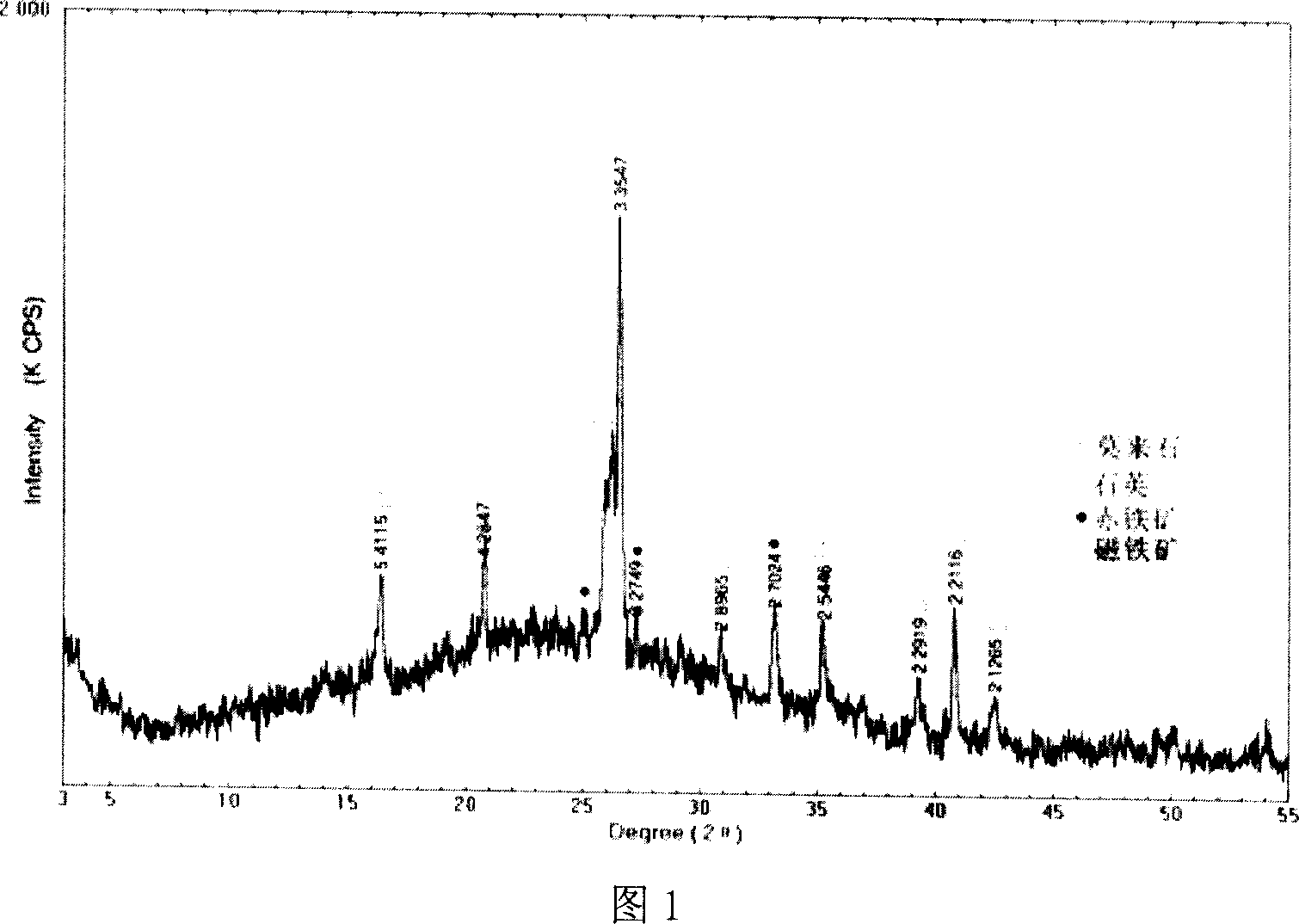

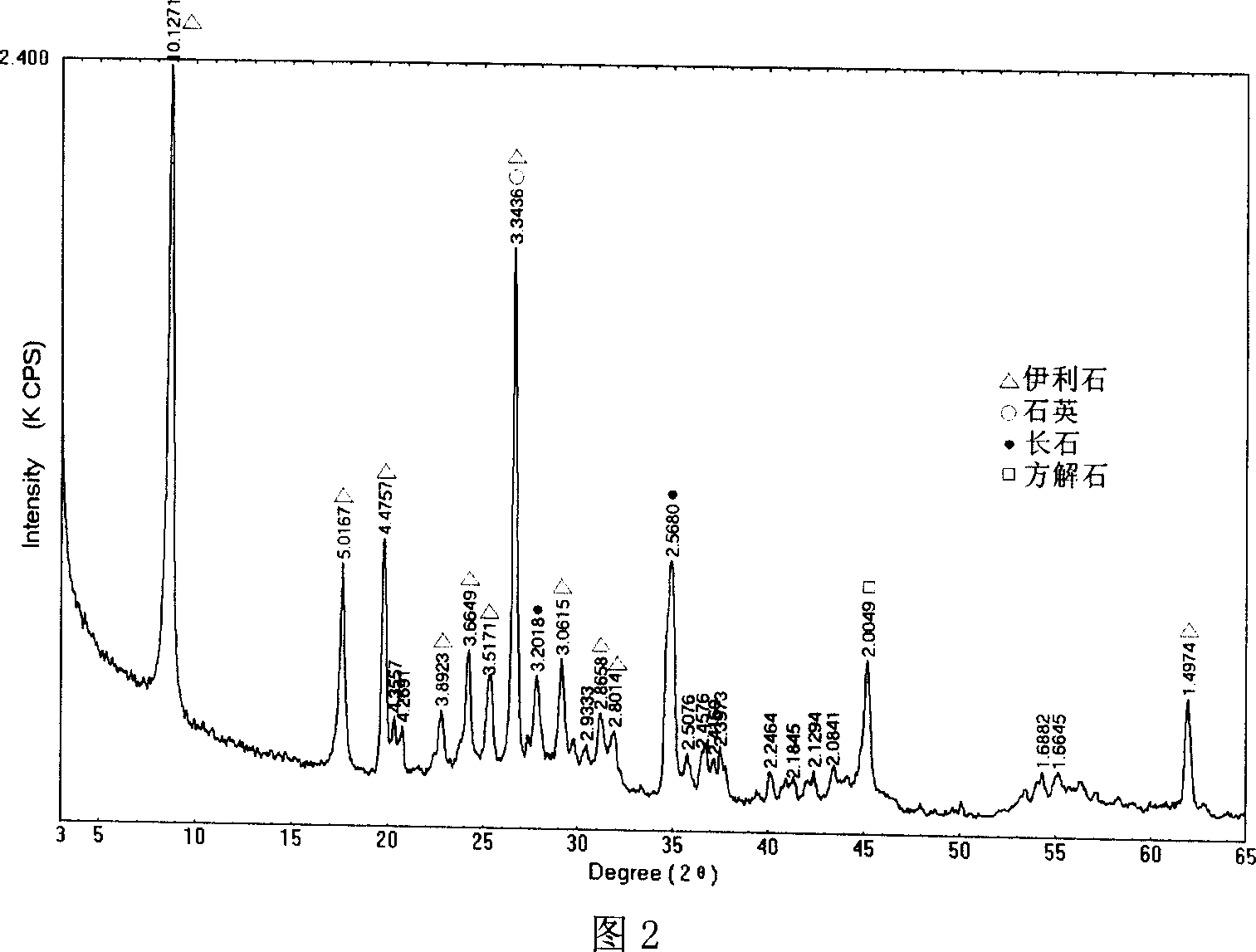

[0048] Weigh 4g of acrylic acid monomer solution in a beaker, and slowly add 7.11 grams of a 25% sodium hydroxide solution to the acrylic acid with a neutralization degree of 80% (mol percent), while stirring to make it fully mixed, and then add 1.20 grams of acrylamide, after fully dissolving, add 0.0016 grams of N, N'-methylenebisacrylamide, mix evenly, then add 1.60 grams of illite (ground to an average particle size of 5.0-15.0 μm by vibratory grinding) and 1.60 grams of fly ash (finely ground by vibration to an average particle size of 5.0-15.0 μm), fully stirred and ultrasonically dispersed (the power of the ultrasonic generator is 200-4000 watts, and the frequency of the ultrasonic wave is 100 kHz-300 MHz , ultrasonic time is 2-10 minutes). Then weigh 0.0120 grams of potassium persulfate and add it to the mixed solution, stir it evenly, place it in a water bath at 70°C for 2-8 hours, observe continuously, and take out the finished product after the reaction conversion r...

Embodiment 2

[0050] Weigh 4g of acrylic acid monomer solution in a beaker, and slowly add 8.00 g of a 25% sodium hydroxide solution to the acrylic acid in a neutralization degree of 90% (mol percent), while stirring to make it fully mixed, and then add 2.00 grams of acrylamide, after fully dissolving, add 0.0016 grams of N, N'-methylenebisacrylamide, mix evenly, then add 1.60 grams of illite (ground to an average particle size of 5.0-15.0 μm by vibratory grinding) and 1.60 grams of fly ash (finely ground by vibration to an average particle size of 5.0-15.0 μm), fully stirred and ultrasonically dispersed (the power of the ultrasonic generator is 200-4000 watts, and the frequency of the ultrasonic wave is 100 kHz-300 MHz , ultrasonic time is 2-10 minutes). Then take 0.0040 grams of potassium persulfate and add it to the mixed solution, stir it evenly, place it in a water bath at 70°C for reaction, and observe continuously. After the reaction conversion rate is greater than 98%, take out the ...

Embodiment 3

[0052] Weigh 4g of acrylic monomer solution in a beaker, slowly add 4.44g of sodium hydroxide solution with a mass percentage of 25% into the acrylic acid according to the degree of neutralization of 50% (mole percent), while stirring to make it fully mixed, and then add 2.00 grams of acrylamide, after fully dissolving, add 0.0016 grams of N, N'-methylenebisacrylamide, mix evenly, then add 1.60 grams of illite (ground to an average particle size of 5.0-15.0 μm by vibratory grinding) and 1.60 grams of fly ash (finely ground by vibration to an average particle size of 5.0-15.0 μm), fully stirred and ultrasonically dispersed (the power of the ultrasonic generator is 200-4000 watts, and the frequency of the ultrasonic wave is 100 kHz-300 MHz , ultrasonic time is 2-10 minutes). Then take 0.0040 grams of potassium persulfate and add it to the mixed solution, stir it evenly, place it in a water bath at 70°C for reaction, and observe continuously. After the reaction conversion rate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com