Method for recycling zinc and cobalt in wet-type smelting zinc purifying slag

A technology of zinc hydro-smelting and recovery method, which is applied in the recycling of zinc and cobalt purification slag from hydro-smelting zinc smelting, can solve the problems of waste of raw materials, etc., and achieve the reduction of usage and high efficiency The effect of reuse value and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

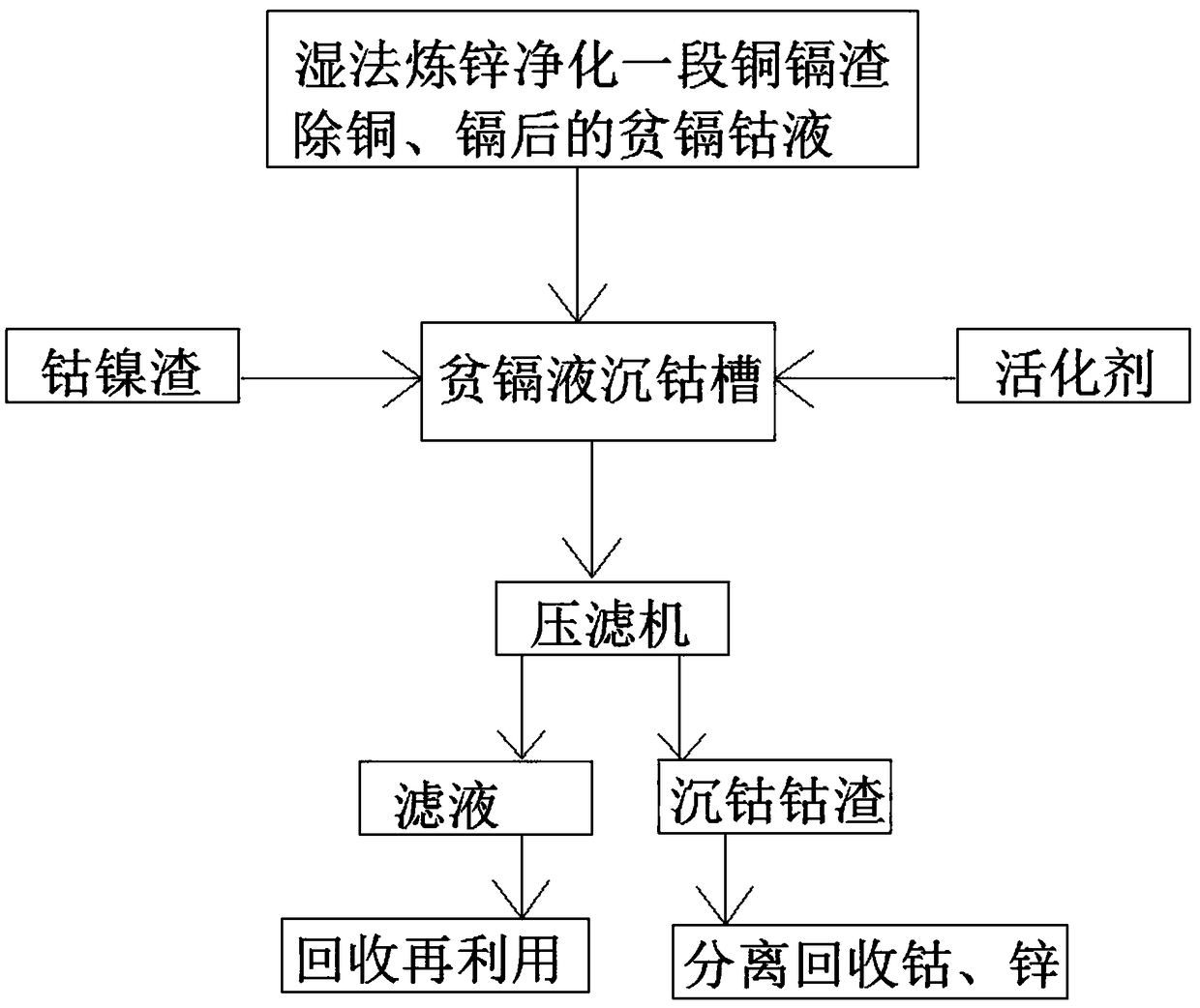

[0026] A method for recovering zinc and cobalt in zinc hydrometallurgy purification slag, the method comprises the following steps:

[0027] S1: Put the cadmium-deficient cobalt liquid solution produced in the cadmium-deficient cobalt precipitation tank after neutral leaching, primary replacement, and secondary replacement of the copper-cadmium slag purified in the first stage of zinc hydrometallurgy, to be treated;

[0028] Among them, the cadmium-depleted cobalt solution placed in the cadmium-depleted cobalt precipitation tank is 40m 3 , wherein the cobalt content is 0.089g / l, and the zinc content is 45.5g / l; S2: recover the cobalt-nickel slag produced in the second stage of zinc hydrometallurgy, and use the acid-containing 150-200g / l waste liquid produced in the electrolysis process to The cobalt-nickel slag is slurried (mixed and stirred), and slurried for 4 hours to obtain slurried pulp;

[0029] The slurried cobalt-nickel slag slurry is transported to the cadmium-poor c...

Embodiment 2

[0035] A method for recovering zinc and cobalt in zinc hydrometallurgy purification slag, the method comprises the following steps:

[0036] S1: Put the cadmium-deficient cobalt liquid solution produced in the cadmium-deficient cobalt precipitation tank after neutral leaching, primary replacement, and secondary replacement of the copper-cadmium slag purified in the first stage of zinc hydrometallurgy, to be treated;

[0037] Among them, the solution placed in the cadmium-poor cobalt precipitation tank is 35m 3 The content of cobalt in this cadmium-depleted cobalt liquid is 0.15g / l, and the content of zinc in the waste liquid is 53.8g / l;

[0038] S2: Recover the cobalt-nickel slag produced in the second stage of zinc hydrometallurgy, use the acidic waste liquid with an acidity of 150-200g / l to slurry the cobalt-nickel slag (mixing and stirring), and perform the slurrying reaction for 3 hours to obtain the slurry;

[0039] The slurried cobalt-nickel slag slurry is transported t...

Embodiment 3

[0045] A method for recovering zinc and cobalt in zinc hydrometallurgy purification slag, the method comprises the following steps:

[0046] S1: Put the cadmium-deficient cobalt liquid solution produced in the cadmium-deficient cobalt precipitation tank after neutral leaching, primary replacement, and secondary replacement of the copper-cadmium slag purified in the first stage of zinc hydrometallurgy, to be treated;

[0047] Among them, the cadmium-deficient cobalt solution placed in the cadmium-deficient cobalt precipitation tank is 30m 3 , the cobalt content in the cadmium-deficient cobalt liquid is 0.26g / l, and the content of zinc in the waste liquid is 55.6g / l;

[0048] S2: Recover the cobalt-nickel slag produced in the second stage of zinc hydrometallurgy, and use the acidic waste liquid with an acidity of 150-200g / l produced in the electrolysis process to slurry the cobalt-nickel slag (mixing and stirring), and the slurrying reaction is 3 hours. Obtain pulped ore pulp; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com