Method for improving grade of fluorite concentrate

A technology of fluorite ore and fluorite, which is applied in the field of improving the grade of fluorite concentrate, can solve the problems of low recovery rate, excessive impurities of fluorite concentrate, and low grade of fluorite concentrate, so as to improve the grade and reduce the content of impurities , Eliminate the effect of large circulation volume of medium ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

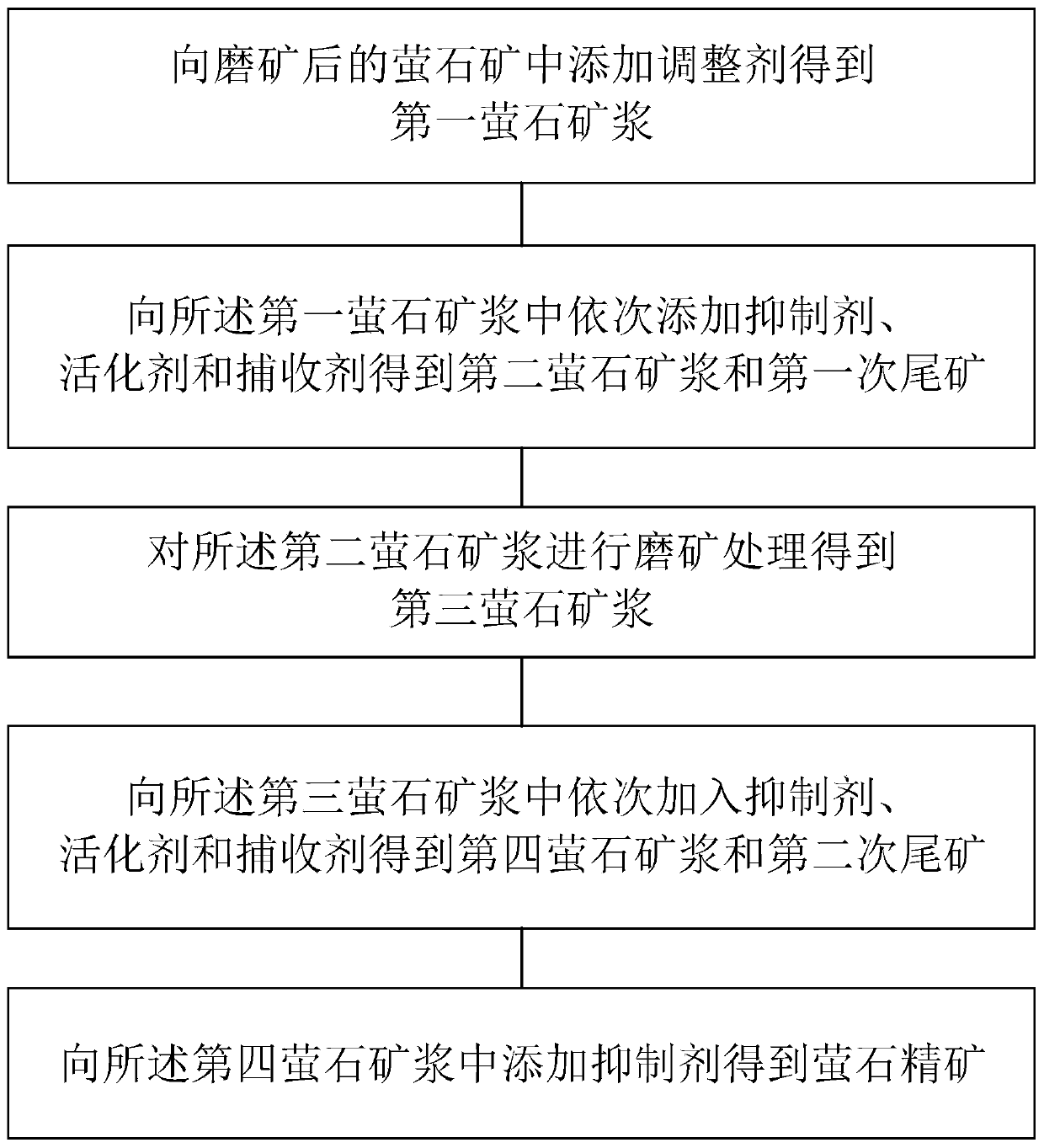

[0032] See figure 1 , figure 1 It is a schematic flowchart of a method for improving the grade of fluorite concentrate provided by the embodiment of the present invention. The embodiment of the present invention provides a method for improving the grade of fluorite concentrate, the method for improving the grade of fluorite concentrate includes:

[0033] Step 1.1, adding a regulator to the ground fluorite ore to obtain the first fluorite slurry;

[0034] Step 1.2, sequentially adding inhibitors, activators and collectors to the first fluorite pulp to obtain the second fluorite pulp and the first tailings;

[0035] Step 1.3, performing grinding treatment on the second fluorite pulp to obtain the third fluorite pulp;

[0036] Step 1.4, adding inhibitor, activator and collector to the third fluorite pulp to obtain the fourth fluorite pulp and the second tailings;

[0037] Step 1.5, adding an inhibitor to the fourth fluorite slurry to obtain fluorite concentrate.

[0038] Flu...

Embodiment 2

[0054] In order to better illustrate the method for improving the grade of fluorite concentrate provided by the embodiment of the present invention, this embodiment will be described by taking a specific beneficiation method as an example on the basis of the above embodiments.

[0055] This embodiment adopts a high-calcium type fluorite mine in a certain place in Ningxia, and the CaF in the raw ore 2 The content is 39.31%, CaCO in raw ore 3 The content of the ore is 20.93%, and the process mineralogy research shows that the ore contains CaCO 3 The minerals are mainly calcite, containing CaF 2 The most common mineral is fluorite, which is a typical high-calcium fluorite ore. This embodiment mainly carries out mineral processing to the high-calcium type fluorite ore in a certain place in Ningxia, and its specific process is as follows:

[0056] Step 2.1, the raw ore is ground with a wet ball mill, so that the amount of fluorite ore after grinding with a particle size of -0.07...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com