Method for treating primary low-grade high-phosphorus manganese ore by acid blending curing

A high-phosphorus manganese ore, low-grade technology, applied in the direction of process efficiency improvement, etc., can solve the problems of unstable microbial transmission variation, not being practically applied, and failing to achieve good results, etc., to achieve good production sustainability and economical comfort Compatibility, easy industrial production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: The chemical composition (mass fraction) of the processed manganese-poor high-phosphorus pyrolusite is: Mn13.38%, Fe1.70%, Al 2 o 3 0.62%, CaO39.48%, MgO1.26%, P0.146%.

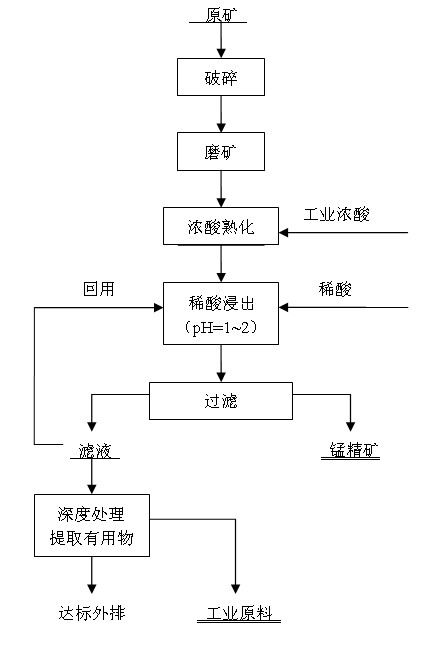

[0023] The process steps adopted are:

[0024] 1.1 Crush low-grade primary high-phosphorus manganese ore into fine-grained raw ore powder, then add concentrated acid and mix evenly, and then place it under normal temperature and pressure for a certain period of time to fully mature the low-grade manganese ore;

[0025] 1.2 Adjust the concentration of the mature mineral powder slurry, and then use dilute acid as a leaching agent at an appropriate temperature and normal pressure to fully carry out the leaching reaction, enrich the manganese in the ore in the leaching slag, and the phosphorus in the leaching residue Phosphoric acid enters the leach solution in the form of phosphoric acid, so that iron, calcium, magnesium and other elements enter the leach solution in the form of water-soluble...

Embodiment 2

[0030] The chemical composition (mass fraction) of the manganese-poor high-phosphorus high-temperature roasted black manganese ore is: Mn18.84%, Fe4.43%, Al 2 o 3 2.52%, CaO50.32%, MgO2.61%, P0.38%.

[0031] The processing steps adopted are the same as in Example 1.

[0032] After the raw ore is crushed, it is sieved to 95% under the 0.2mm sieve. Take 100 grams of sieved raw ore powder, stir evenly in a reaction vessel with 80ml of industrial dilute nitric acid (concentration 68%), place it at room temperature for 1.5 days (36h), and use dilute nitric acid (pH=1) as a leaching agent after aging to adjust the slurry The material concentration is 100g / L, leaching at 40°C for 2 hours, so that phosphorus enters the leaching solution in the form of phosphoric acid, and iron, calcium, magnesium, aluminum, etc. in the form of nitrate. Then it is separated by filtration and washed to obtain manganese-rich slag.

[0033] It is measured that the manganese-rich slag contains Mn44.47%...

Embodiment 3

[0034] Example 3: The chemical composition (mass fraction) of the processed manganese-poor high-phosphorus ferromanganese ore is: Mn20.91%, Fe18.46%, Al 2 o 3 6.10%, CaO1.51%, MgO0.54%, P0.39%.

[0035] The processing steps adopted are the same as in Example 1.

[0036] After the raw ore is crushed, it is sieved to 95% under the 0.1mm sieve. Take 500 grams of sieved raw ore powder, stir evenly in a reaction vessel with 150ml industrial concentrated sulfuric acid (concentration 98%), place it at room temperature for 1 day (24h), use dilute sulfuric acid (pH=1) as a leaching agent after aging, and adjust the slurry The material concentration is 200g / L, and the temperature is leached at 60°C for 3 hours, so that phosphorus enters the leaching solution in the form of phosphoric acid, and iron, calcium, magnesium, aluminum, etc. in the form of sulfate. Then it is separated by filtration and washed to obtain manganese-rich slag.

[0037]It is measured that the manganese-rich sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com