Beneficiation comprehensive recovery method for low-grade iron-containing uranium ore

A recovery method and uranium ore technology, applied in the field of uranium ore beneficiation, can solve the problems of poor economic benefit and high production cost, and achieve the effect of reducing iron grade, improving grade and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

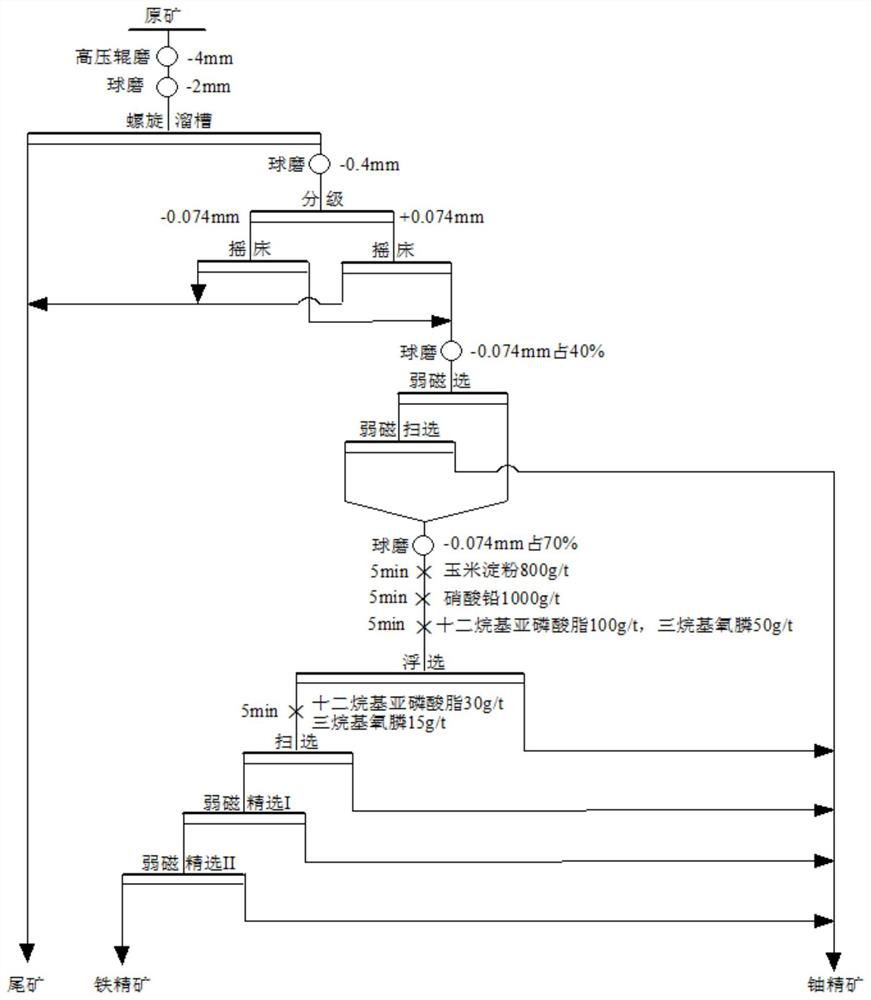

Method used

Image

Examples

Embodiment 1

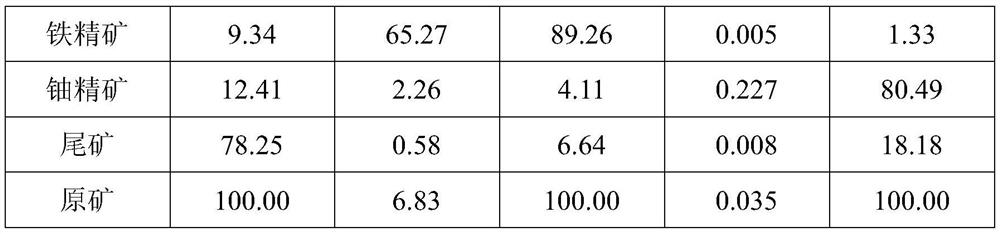

[0032] The main uranium mineral in a certain iron-bearing uranium ore is crystalline uranium ore, followed by pitchblende. The uranium grade in the ore is low, with a uranium grade of 0.035%. The iron-bearing minerals include magnetite, hematite, and pyrite. More than 95% is magnetite, the iron grade is 6.83%, and the gangue minerals are mainly serpentine, feldspar, quartz, biotite, muscovite, fluorite, calcite, zircon, monazite, chlorite, etc.

[0033] (1) The ore is crushed to -5mm with a high-pressure roller mill. After the ore is crushed, the ore fineness is ground to -3mm with a ball mill, and the tailings are pre-thrown with a spiral chute to obtain a spiral chute concentrate and a spiral chute tailings.

[0034] (2) The spiral chute concentrate obtained in step (1) is ground with a ball mill, and the fineness is ground to -0.6mm, and the sieve with a sieve size of 0.074mm is divided into two parts of +0.074mm and -0.074mm, respectively. Sorting by shaking table to obtai...

Embodiment 2

[0046] The main uranium mineral in a certain iron-bearing uranium ore is crystalline uranium ore, followed by pitchblende. The uranium grade in the ore is low, with a uranium grade of 0.035%. The iron-bearing minerals include magnetite, hematite, and pyrite. More than 95% is magnetite, the iron grade is 6.83%, and the gangue minerals are mainly serpentine, feldspar, quartz, biotite, muscovite, fluorite, calcite, zircon, monazite, chlorite, etc.

[0047] In this example, the effect of flotation deuranization on the radioactivity of iron ore concentrates is compared. The process of test A has flotation deuranization, and the process of test B has no process of flotation deuranization.

[0048] (1) Test A and Test B ores are crushed to -4mm by high-pressure roller mill respectively. After the ore is crushed, the ore fineness is ground to -2mm by ball mill, and tailings are pre-thrown by spiral chute to obtain spiral chute concentrate and spiral chute. Chute tailings.

[0049] (2...

Embodiment 3

[0063] The main uranium mineral in a certain iron-bearing uranium ore is crystalline uranium ore, followed by pitchblende. The uranium grade in the ore is low, with a uranium grade of 0.035%. The iron-bearing minerals include magnetite, hematite, and pyrite. More than 95% is magnetite, the iron grade is 6.83%, and the gangue minerals are mainly serpentine, feldspar, quartz, biotite, muscovite, fluorite, calcite, zircon, monazite, chlorite, etc.

[0064] This example compares the flotation effects of uranium under the condition of adding different dosages of uranium mineral activator lead nitrate, which are numbered test A, test B, test C and test D respectively.

[0065] (1) Test A, Test B, Test C, and Test D four groups of ores were respectively crushed to -3mm by high-pressure roller mill. Tails, get spiral chute concentrate and spiral chute tailings.

[0066] (2) Grind the spiral chute concentrates obtained in Test A, Test B, Test C, and Test D steps (1) with a ball mill, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com