Method for preparing artificial rutile from titanium concentrate

A technology of artificial rutile and titanium concentrate, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of restricting industrial production, high product pulverization rate, and high raw material requirements, so as to reduce product pulverization rate and simple equipment , Improve the effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

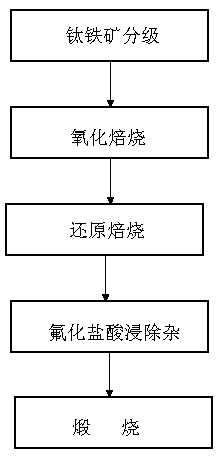

[0028] Such as figure 1 Shown, a kind of method for preparing artificial rutile by titanium concentrate, is characterized in that: described method for preparing artificial rutile by titanium concentrate comprises the following steps:

[0029] S1, classifying ilmenite, classifying the ilmenite, and selecting ilmenite larger than 100 μm for later use;

[0030] S2, oxidation roasting: the ilmenite selected in step S1 is oxidized and roasted at 600°C for 2 hours to obtain ilmenite oxide;

[0031] S3, reduction roasting: reducing and roasting the oxidized ilmenite obtained in step S2 at 800° C. for 1 to 2 hours to obtain modified ilmenite;

[0032] S4, fluoride hydrochloric acid leaching to remove impurities: uniformly mix the modified ilmenite obtained in step S3 with an inorganic acid with a concentration of 15wt%, react at 95°C for 5 hours, and then add fluoride salt to the reaction, Continue to react for 2 hours, then filter the reactant with suction, wash with water and dry...

Embodiment 2

[0044] Such as figure 1 Shown, a kind of method for preparing artificial rutile by titanium concentrate, is characterized in that: described method for preparing artificial rutile by titanium concentrate comprises the following steps:

[0045] S1, classifying ilmenite, classifying the ilmenite, and selecting ilmenite larger than 100 μm for later use;

[0046] S2, oxidation roasting: the ilmenite selected in step S1 is oxidized and roasted at 1000°C for 0.5h to obtain ilmenite oxide;

[0047]S3, reduction roasting: reducing and roasting the oxidized ilmenite obtained in step S2 at 1000°C for 1 hour to obtain modified ilmenite;

[0048] S4, fluoride hydrochloric acid leaching to remove impurities: uniformly mix the modified ilmenite obtained in step S3 with an inorganic acid with a concentration of 25wt%, react at 105°C for 3 hours, and then add fluoride salt to the reaction, Continue to react for 1 hour, then filter the reactant with suction, wash with water and dry to obtain...

Embodiment 3

[0060] Such as figure 1 Shown, a kind of method for preparing artificial rutile by titanium concentrate, is characterized in that: described method for preparing artificial rutile by titanium concentrate comprises the following steps:

[0061] S1, classifying ilmenite, classifying the ilmenite, and selecting ilmenite larger than 100 μm for later use;

[0062] S2, oxidative roasting: the ilmenite selected in step S1 is oxidized and roasted at 800°C for 1.5 hours to obtain ilmenite oxide;

[0063] S3, reduction roasting: reducing and roasting the oxidized ilmenite obtained in step S2 at 900° C. for 1.5 hours to obtain modified ilmenite;

[0064] S4, fluoride hydrochloric acid leaching to remove impurities: uniformly mix the modified ilmenite obtained in step S3 with an inorganic acid with a concentration of 20wt%, react at 100°C for 4.5h, and then add fluoride salt to the reaction , continue to react for 1.5h, and then carry out suction filtration, water washing and drying to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com