Beneficiation process for sorting monazite and rutile by using composite collecting agent and application thereof

A compound collector and monazite technology, which is applied in the direction of process efficiency improvement, flotation, solid separation, etc., can solve the problems such as strong acid and strong alkali are not suitable, so as to improve the operation recovery rate, good economic benefits, and reduce water glass The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

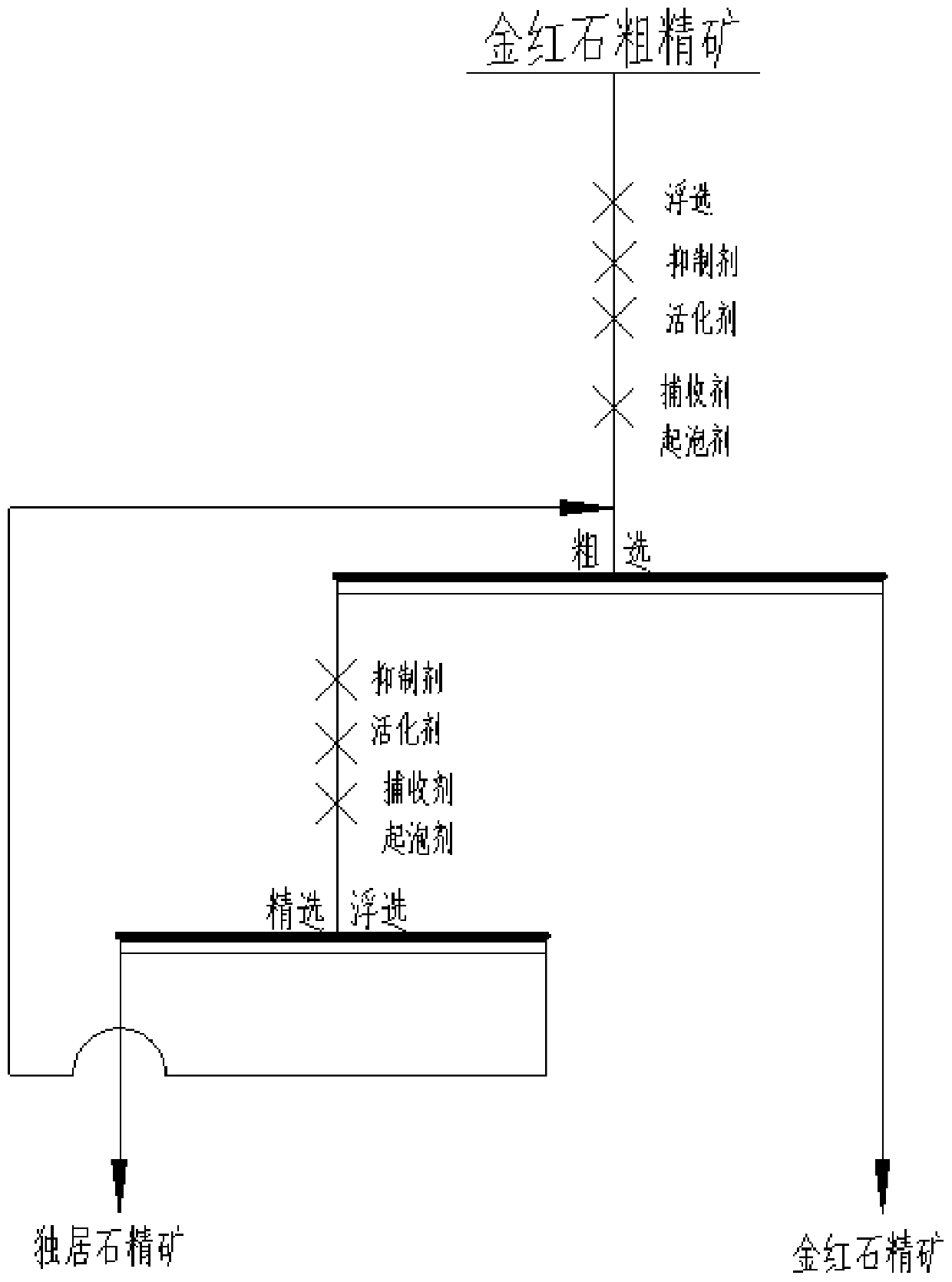

Method used

Image

Examples

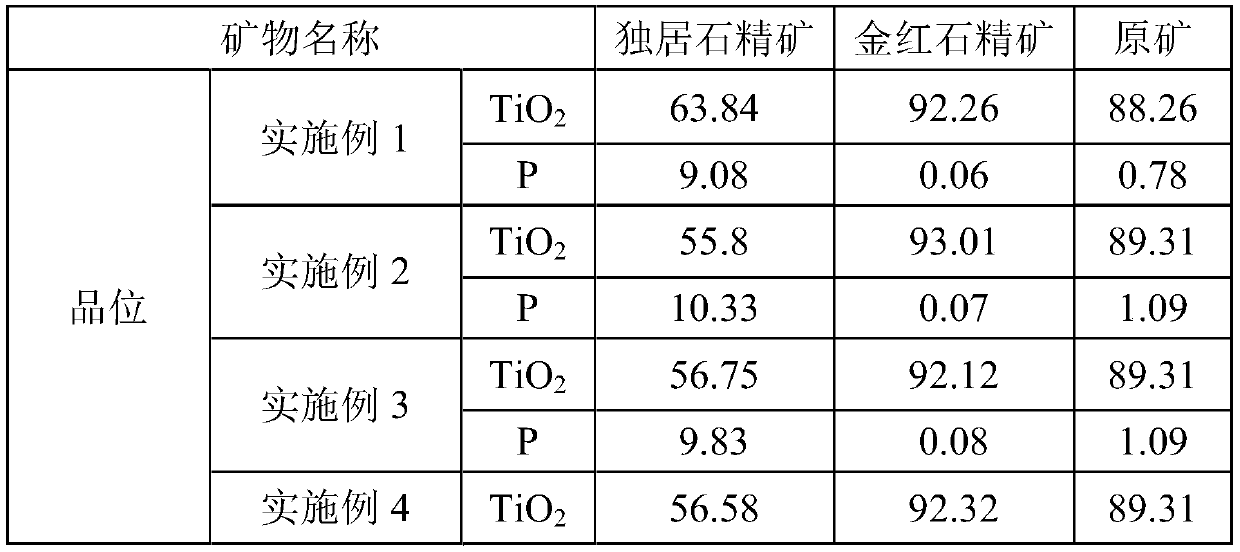

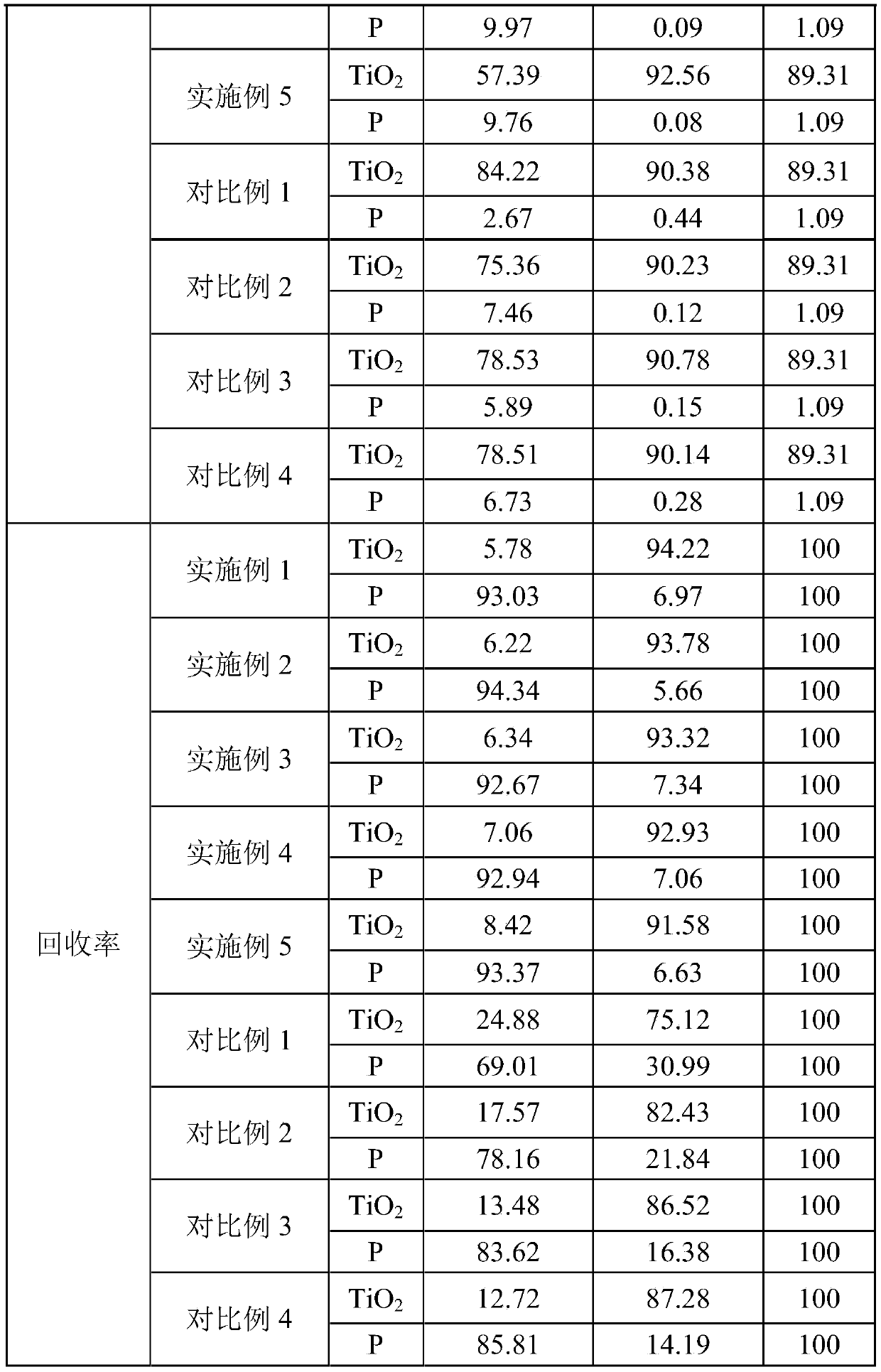

Embodiment 1

[0031] The raw material processed in this example is Mozambique rutile rough concentrate of Hainan Haituo Mining Co., Ltd., wherein the rough concentrate contains TiO 2 88.26%, including P 0.78%. Among them, rutile is the main component, and there are also some monazite, zircon and a small amount of garnet.

[0032] A kind of beneficiation process utilizing composite collector to separate monazite and rutile, comprising the following steps:

[0033] (1) Preparation of collector: by weight, 10 parts of tall oil, 25 parts of oxidized paraffin soap, 50 parts of palm oil, 15 parts of sodium fatty acid methyl ester sulfonate are mixed, microwave preactivation 8min, microwave power 10kg / kw, microwave frequency 2500MHz; after microwave activation, add 10 parts by weight of sodium hydroxide, and saponify at 100°C for 1.5h to obtain the target collector;

[0034] (2) Rough separation: take rutile coarse concentrate raw material, add collector 250g / t prepared in step (1), inhibitor w...

Embodiment 2

[0037] The raw material processed in this example is a rutile rough concentrate in Australia of Fujian Wensheng Mining Co., Ltd., wherein the rough concentrate contains TiO 2 89.31%, including P1.09%. Among them, rutile is the main component, and there are also some monazite, zircon and a small amount of garnet.

[0038] A kind of beneficiation process utilizing composite collector to separate monazite and rutile, comprising the following steps:

[0039] (1) Preparation of collector: by weight, 10 parts of tall oil, 25 parts of oxidized paraffin soap, 50 parts of palm oil, 15 parts of sodium fatty acid methyl ester sulfonate are mixed, microwave preactivation 8min, microwave power 10kg / kw, microwave frequency 2500MHz; after microwave activation, add 10 parts by weight of sodium hydroxide, and saponify at 100°C for 1.5h to obtain the target collector;

[0040] (2) Rough separation: take rutile coarse concentrate raw material, add collector 300g / t prepared in step (1), inhibit...

Embodiment 3

[0043] A kind of beneficiation process utilizing composite collector to separate monazite and rutile, comprising the following steps:

[0044](2) roughing: get the rutile coarse concentrate raw material consistent with embodiment 2, add collector 200g / t that embodiment 1 makes, suppressor water glass 600g / t, activator copper sulfate 100g / t, start Foam agent No. 2 oil 40g / t, conduct the first flotation, the flotation concentration is 40-50%, and the flotation time is 20min, to obtain monazite coarse concentrate and tailings;

[0045] (3) Concentration: the monazite rough concentrate that step (2) obtains, add the collector 120g / t that step (1) makes, inhibitor water glass 400g / t, activator copper sulfate 80g / t, Foaming agent No. 2 oil 25g / t, carry out the second flotation, the flotation concentration is 35-45%, the flotation time is 8min, filter and dry to obtain monazite concentrate and rutile tailings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com