Non-oriented electrical steel plate without corrugated defect and its manufacturing method

A technology of oriented electrical steel sheets without corrugation, applied in the direction of inorganic materials such as magnetism, can solve the problems of high production costs, achieve the effects of easy adjustment, low implementation difficulty, and avoid precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

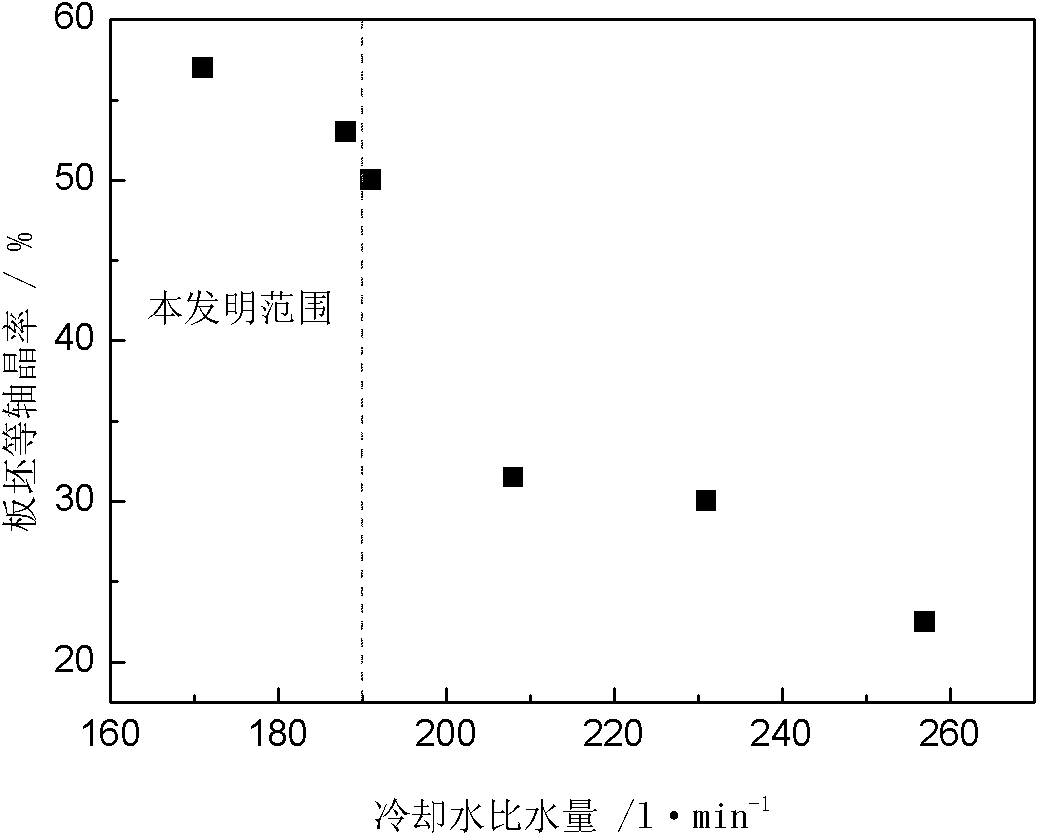

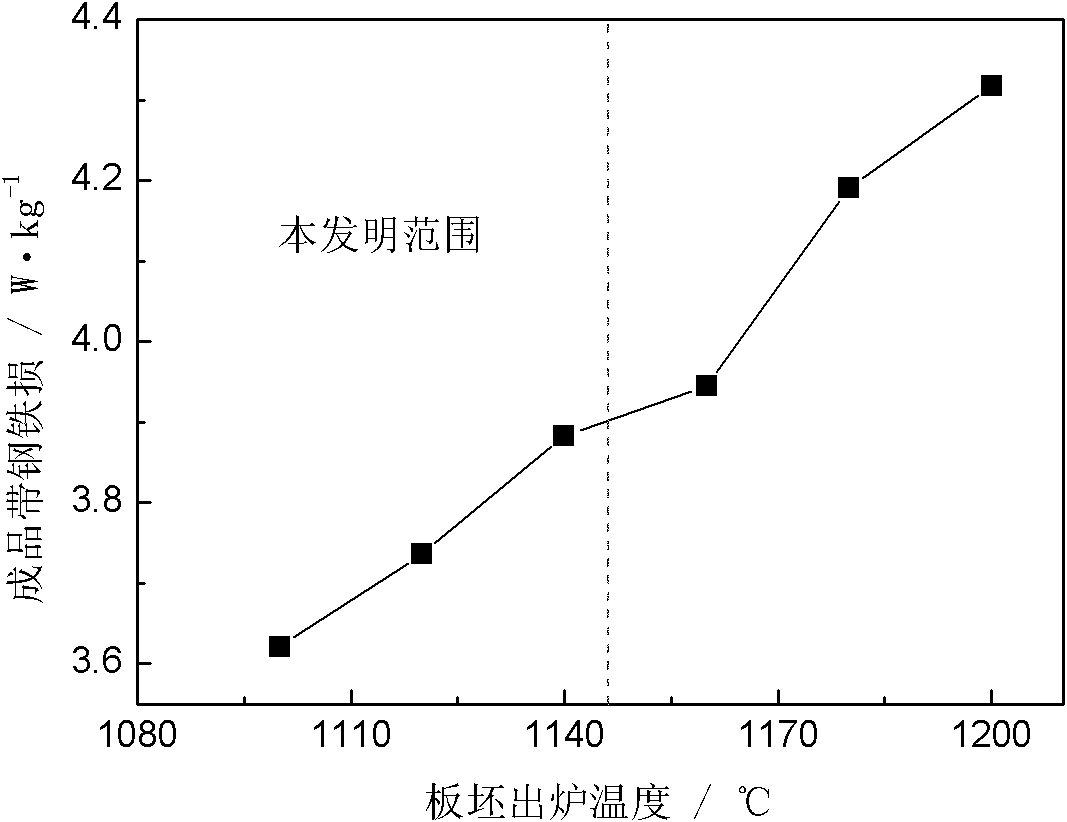

[0045] The chemical composition of molten steel in the continuous casting tundish is controlled as follows: C: 0.001%, Si: 1.22%, Mn: 0.25%, P: 0.02%, S: 0.003%, Al: 0.33%, N: 0.001%, O: 0.004% , the balance is Fe and unavoidable inclusions. The average superheated degree of molten steel is 34.6°C, the casting speed is 1.07m / min, the specific cooling water volume is 185l / min, the slab temperature drop rate is 11.6min / °C, the surface temperature of the slab at the exit of the casting machine is 710°C, and the equiaxed crystal ratio is 43%. In the heating furnace, the temperature difference at the watermark point is 22°C, the residence time in the soaking section of the slab is 46min, and it is rolled after being heated at 1125°C×3h. The hot-rolled plate is rolled into a 0.5mm thick strip steel by a cold rolling method, and then continuously annealed in a dry atmosphere. There are no corrugated defects on the surface of the finished strip steel, iron loss: 4.743W / kg, magnetic i...

Embodiment 2

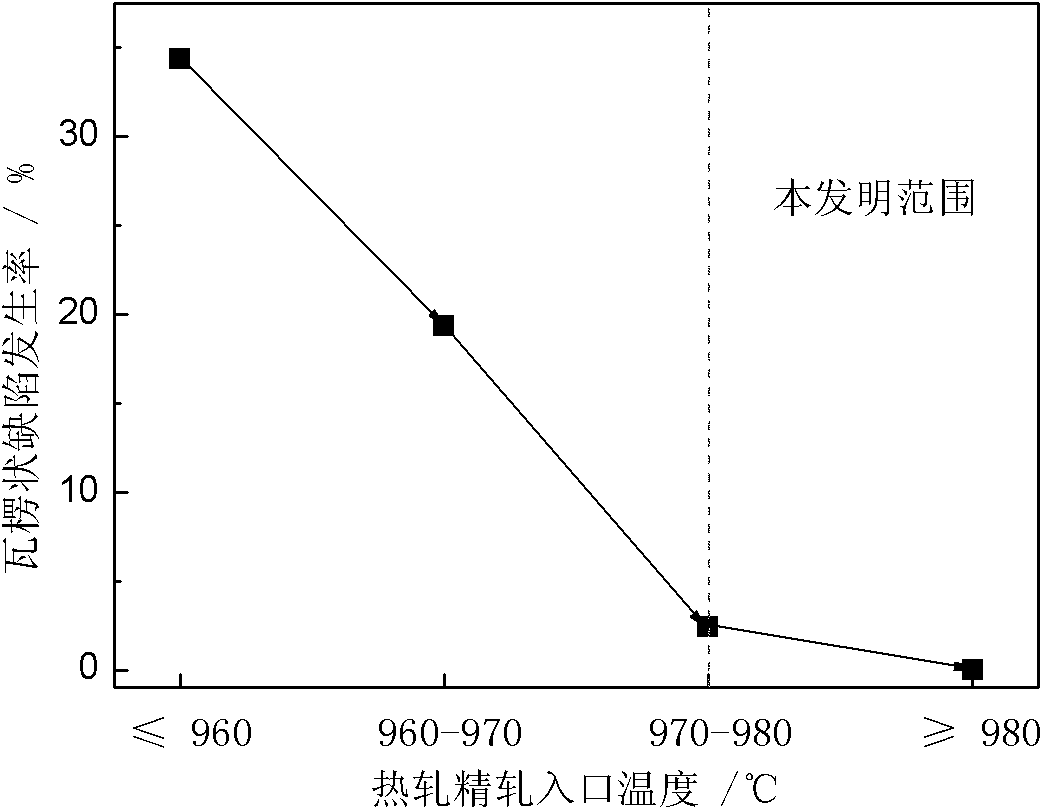

[0047] The chemical composition of molten steel in the continuous casting tundish is controlled as follows: C: 0.002%, Si: 1.42%, Mn: 0.30%, P: 0.06%, S: 0.002%, Al: 0.25%, N: 0.002%, O: 0.002% , the balance is Fe and unavoidable inclusions. The average superheated degree of molten steel is 31.4°C, the casting speed is 1.04m / min, the specific cooling water volume is 175l / min, the slab temperature drop rate is 9.6min / °C, the surface temperature of the slab at the exit of the casting machine is 680°C, and the equiaxed crystal ratio is 57%. In the heating furnace, the watermark point temperature difference is 22°C, the slab soaking section residence time is 48min, and rolled after being heated at 1135°C×3h, the finish rolling entrance temperature is 973°C, the final rolling temperature is 853°C, and the coiling temperature is 563°C. The hot-rolled plate is rolled into a 0.5mm thick strip steel by a cold rolling method, and then continuously annealed in a dry atmosphere. There ar...

Embodiment 3

[0049] The chemical composition of molten steel in the continuous casting tundish is controlled as follows: C: 0.002%, Si: 1.49%, Mn: 0.49%, P: 0.02%, S: 0.003%, Al: 0.59%, N: 0.001%, O: 0.002% , the balance is Fe and unavoidable inclusions. The average superheated degree of molten steel is 28.7°C, the casting speed is 0.99m / min, the specific cooling water volume is 189l / min, the slab temperature drop rate is 8.7min / °C, the surface temperature of the slab at the exit of the casting machine is 660°C, and the equiaxed crystal ratio is 63%. In the heating furnace, the temperature difference at the watermark point is 24°C, the residence time in the soaking section of the slab is 53min, and it is rolled after being heated at 1102°C×3h. The hot-rolled plate is rolled into a 0.5mm thick strip steel by a cold rolling method, and then continuously annealed in a dry atmosphere. There are no corrugated defects on the surface of the finished strip steel, iron loss: 3.559W / kg, magnetic in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com