Ultralow carbon aluminum silicon killed steel and production method thereof

A technology for silicon-killed steel and its production method, which is applied in ultra-low-carbon aluminum-silicon-killed steel and its production field, can solve the problems of narrow superheat range of molten steel, affecting normal operation of continuous casting, difficulty in effective control, etc., and achieves low implementation difficulty , Easy to adjust, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment.

[0038] Refer to Table 1 for the steel composition examples of the present invention, and refer to Table 2 for the production process.

[0039]Molten iron and steel scrap are matched according to the proportion. After 300 tons of converter smelting, RH refining and deoxidation, alloying, and then continuous casting, a continuous casting slab with a thickness of 170-250mm and a width of 800-1400mm is finally obtained. See Table 2 for the control of equiaxed grain ratio in steel.

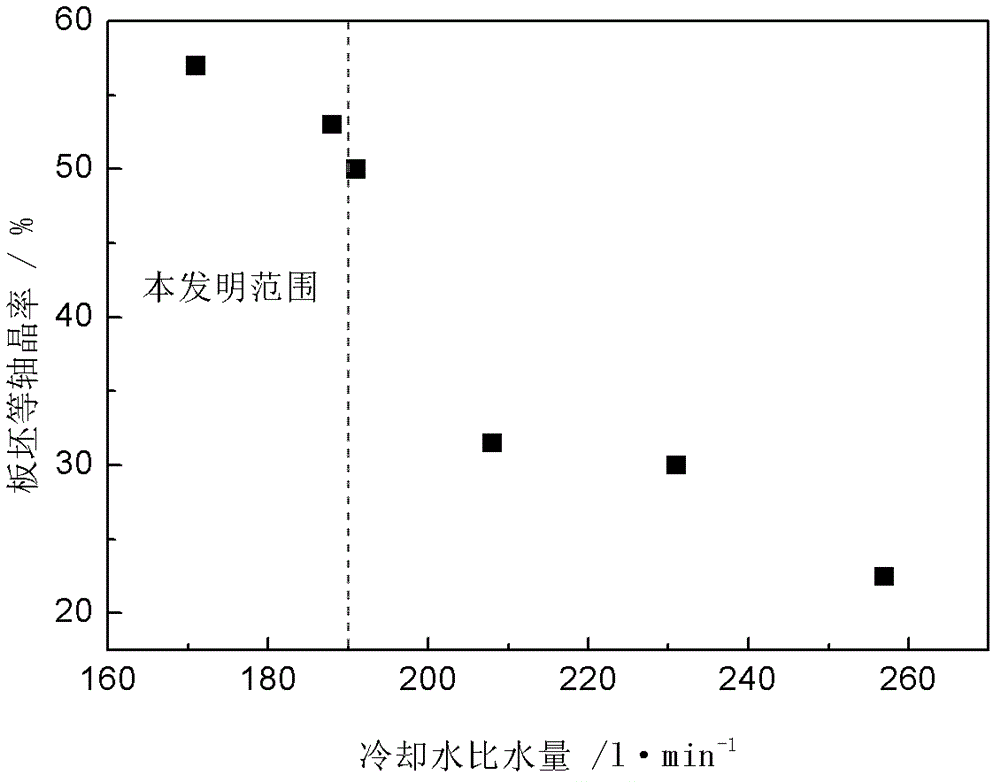

[0040] figure 1 It is the relationship between the ratio of continuous casting cooling water and the equiaxed crystal ratio of the slab. As shown in the figure, on the premise of not using electromagnetic stirring, the equiaxed grain rate in the slab is significantly increased by reducing the specific water volume of cooling water and strictly controlling it below 190l / min. In the embodiment, when the degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com