Processing box

A technology for processing boxes and shells, which is applied in the field of processing boxes and can solve problems such as jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

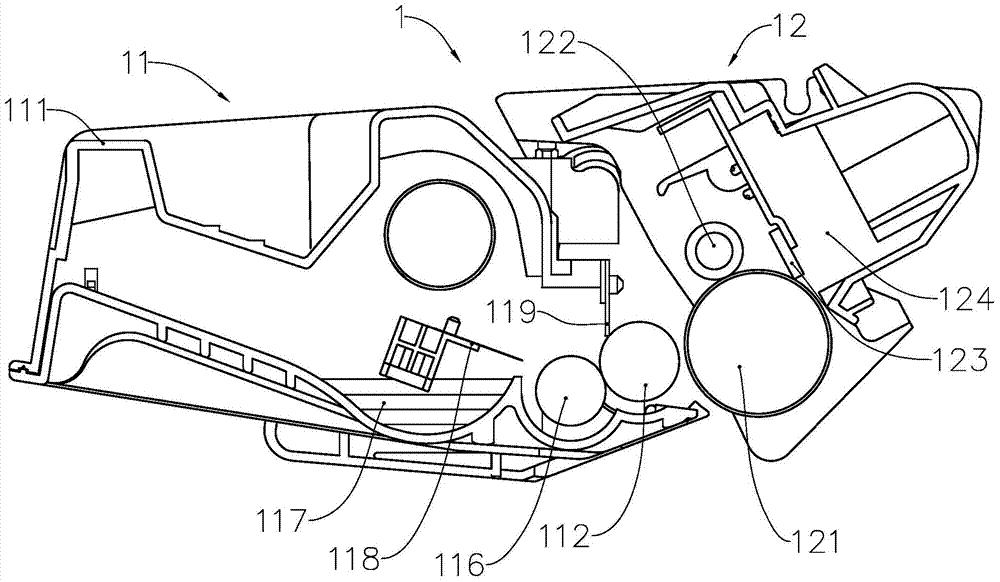

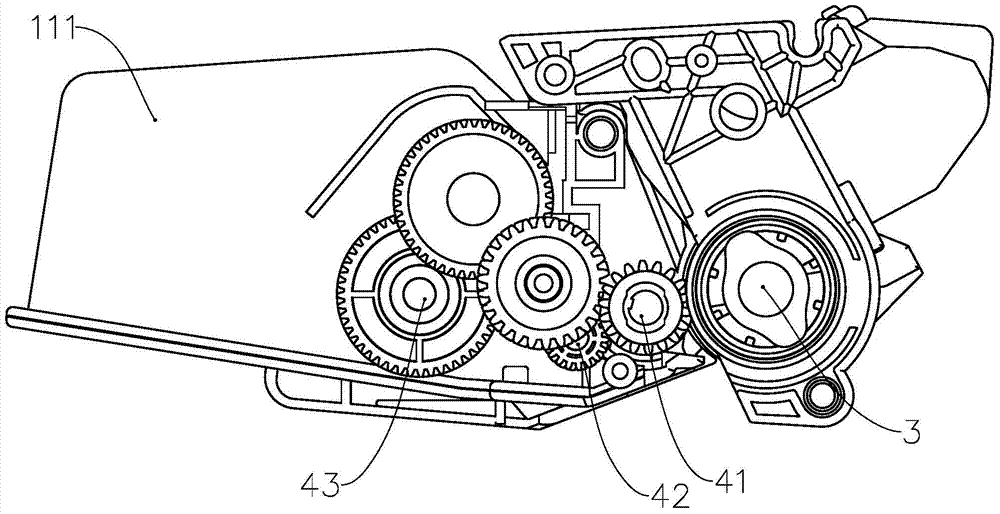

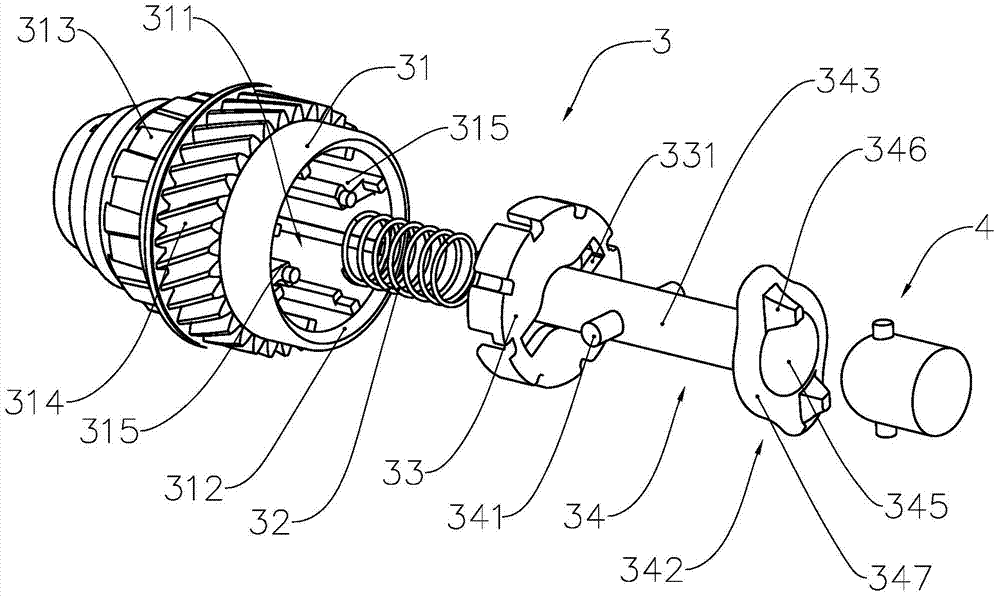

[0048] refer to Figure 5 , Figure 5 is a structural diagram of the process cartridge of this embodiment. The process box 5 comprises a developing unit 51 and a drum unit 52. On the same side of the developing unit 51 and the drum unit 52, a gear protection cover 53 is arranged. A gear transmission system is installed in the gear protection cover 53. At the end of the photosensitive drum of the drum unit 52 The driving assembly 7 is arranged on the upper part, and the driving assembly 7 receives the external driving force and transmits the driving force to the gear transmission system inside the gear protection cover 53 . The developing unit 51 includes a housing, which surrounds a cavity containing consumables such as carbon powder or developer, and a touch device 6 is installed on the outer side of the housing where the developing unit 51 is located on the same side as the drive assembly 7, The touch device 6 is disposed inside the gear protection cover 53 , and a part of...

no. 2 example

[0055] On the basis of the first embodiment of the process cartridge, the developing unit can also be provided with a chute on the outer wall on the same side as the driving assembly, and the chute can be extended along the installation direction or perpendicular to the installation direction. The first end of the chute is arranged at a position far away from the driving assembly, or at a position far away from any gear in the gear transmission system connected with the first gear part. And the second end of the chute is arranged at a position close to the driving assembly, or at a position close to any gear in the gear transmission system connected with the first gear part. When the processing box is in normal working condition, by setting the fixed shaft with the gear member on the first end of the chute, the touch control device will not affect the normal operation of the processing box in the normal working state of the processing box. . When the process box is pulled out...

no. 3 example

[0059] On the basis of the first embodiment of the process box, the touch device can also be installed and fixed on the end face of any gear in the gear transmission system. By setting a part of the operation part of the touch device to be exposed outside the gear protection cover, it can The purpose of the present invention can also be achieved by adjusting the exposed operating portion so that the driving force receiving member rotates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com