Method for preparing fatty acid starch ester and application

A fatty acid and starch ester technology, applied in the field of modified starch, can solve the problems of affecting product quality, local reaction, long reaction time, etc., and achieve the effects of good freeze-thaw stability, easy adjustment and control, and continuous reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

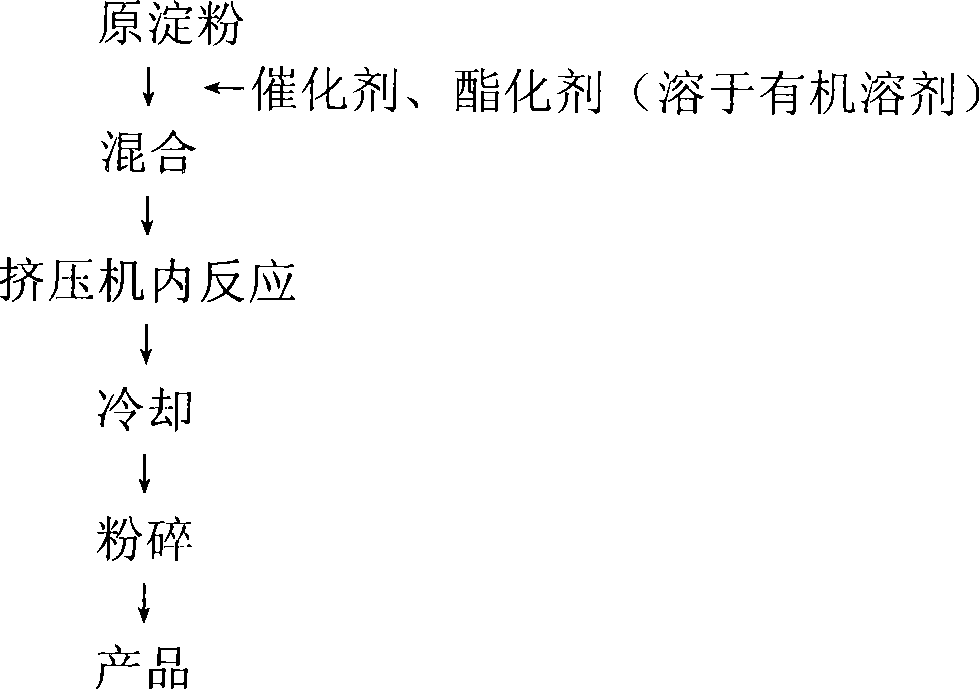

Method used

Image

Examples

Embodiment 1

[0032] A kind of extrusion method prepares the method for fatty acid starch ester, comprises the following steps successively: take by weighing 300g (dry basis) cornstarch, 60mL hot dehydrated alcohol dissolves 9g stearic acid, makes catalyst with 2mol / L hydrochloric acid, and addition is 1.0 mL, and then fully mixed with starch in a blender, evaporated ethanol at 50°C, and adjusted the water to 26%. The feeding speed of the extruder is 100g / min, the sleeve temperature of each section of the extruder (from the feed to the discharge end) is 30°C in the first section, 60°C in the second section, 90°C in the third section, and 120°C in the fourth section , the screw speed is 100r / min, cooled and pulverized to obtain the finished product. The type of screw extruder used is a twin-screw extruder, and it is a full-mesh type.

[0033] Compare as shown in table 1 with the prepared starch stearate and the starch stearate performance prepared by microwave method and high temperature me...

Embodiment 2

[0039] A kind of extrusion method prepares the method for starch stearate, comprises the following steps successively: take by weighing 300g (dry base) wheat starch, 60mL hot dehydrated alcohol dissolves 12g stearic acid, makes catalyzer with 2mol / L hydrochloric acid, addition 0.4mL, then fully mixed with starch in a blender, evaporated ethanol at 50°C, and adjusted the water to 20%. The feeding speed of the extruder is 125g / min, the sleeve temperature of each section of the extruder (from the feed to the discharge end) is 50°C in the first section, 80°C in the second section, 110°C in the third section, and 140°C in the fourth section , the screw speed is 120r / min, cooled and pulverized to obtain the finished product. The type of screw extruder used is a single screw extruder.

Embodiment 3

[0041] Use oleic acid as the esterification agent, rice starch as raw material, all the other formulas and operating conditions are the same as in Example 1 or Example 2, to obtain the finished starch oleate ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com