Vetical cracking tower for cracking used tyre and recovering industrial carbon black and fuel oil

A technology for waste tires and fuel oil, which is applied in the petroleum industry, fibrous fillers, and the preparation of liquid hydrocarbon mixtures. It can solve the problems of difficult to adopt segmental heating, high inlet flue gas temperature, and lower heat transfer coefficient, etc., and achieve Guaranteed quality and safety, stable operation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

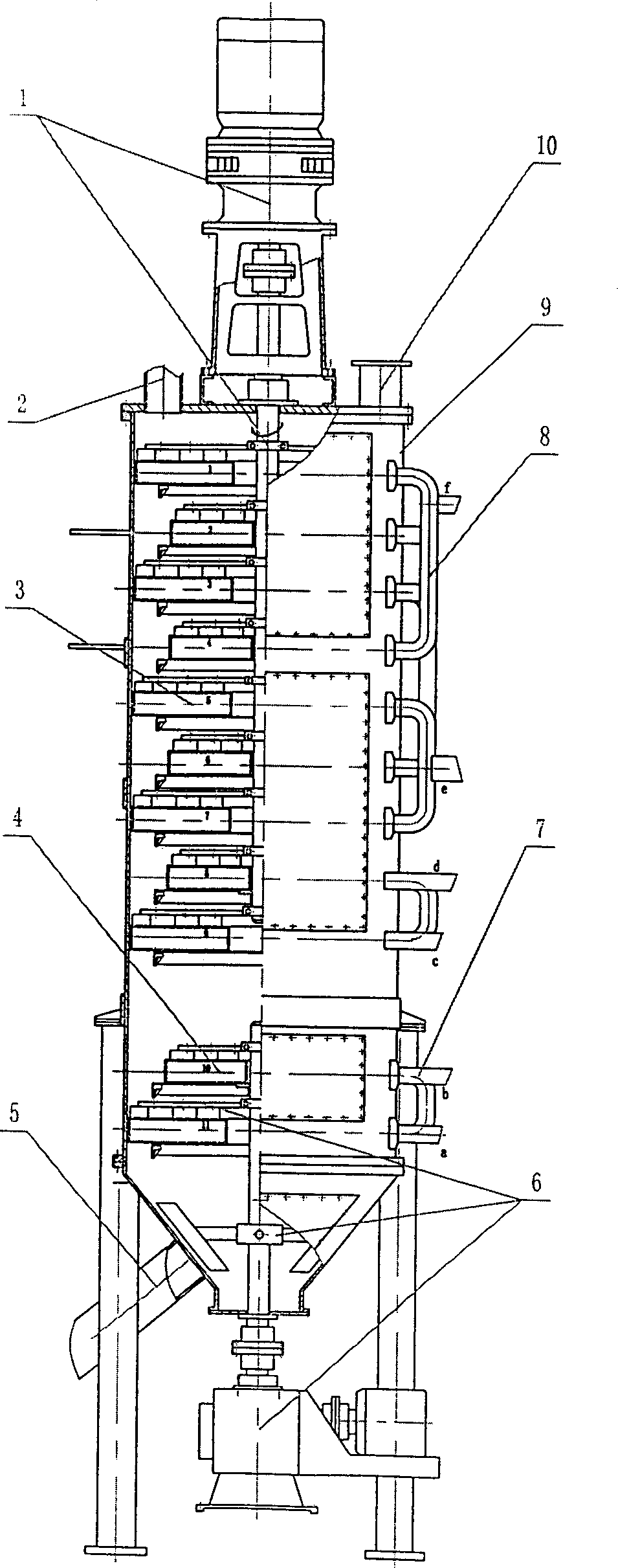

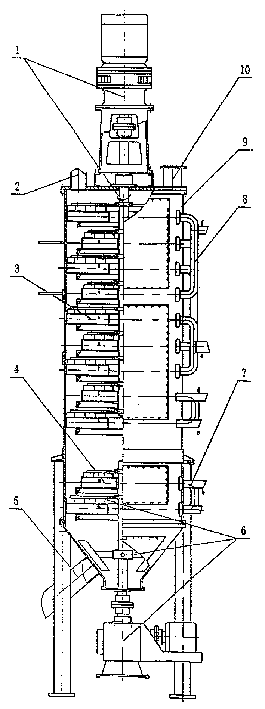

[0012] The vertical pyrolysis tower used for pyrolysis of waste tires to recover industrial carbon black and fuel oil has a closed vertical tower body 9, and an upper scraping and stirring device 1, a tire feed port 10 and a pyrolysis gas outlet 2 are arranged on the upper end of the tower body. The upper hollow heating disc 3 and the lower hollow cooling disc 4 are arranged in sequence in the body, and are respectively connected with the flue gas distribution system 8 outside the tower body and the cooling water inlet and outlet header 7, and the lower scraping material is arranged under the tower body Stirring device 6 and carbon black outlet 5 at the bottom of the tower.

[0013] The hollow heating disk 3 on the upper part of the tower is a hollow heating disk arranged statically and alternately in size, wherein the center of the large disk has a large hole, the outer edge and the tower wall are provided with a small gap, the center of the small disk has a small hole, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com