Sowing and fertilizer application machine with characteristic of convenient adjustment control

A technology of adjusting control and fertilizer applicator, which is applied in the directions of sowing, fertilizer applicator, fertilizer distributor, etc., can solve the problems of inability to observe materials at any time, inconvenient adjustment and control, and small load bearing of the bracket, so as to achieve convenient adjustment and control, large bearing capacity, The effect of strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

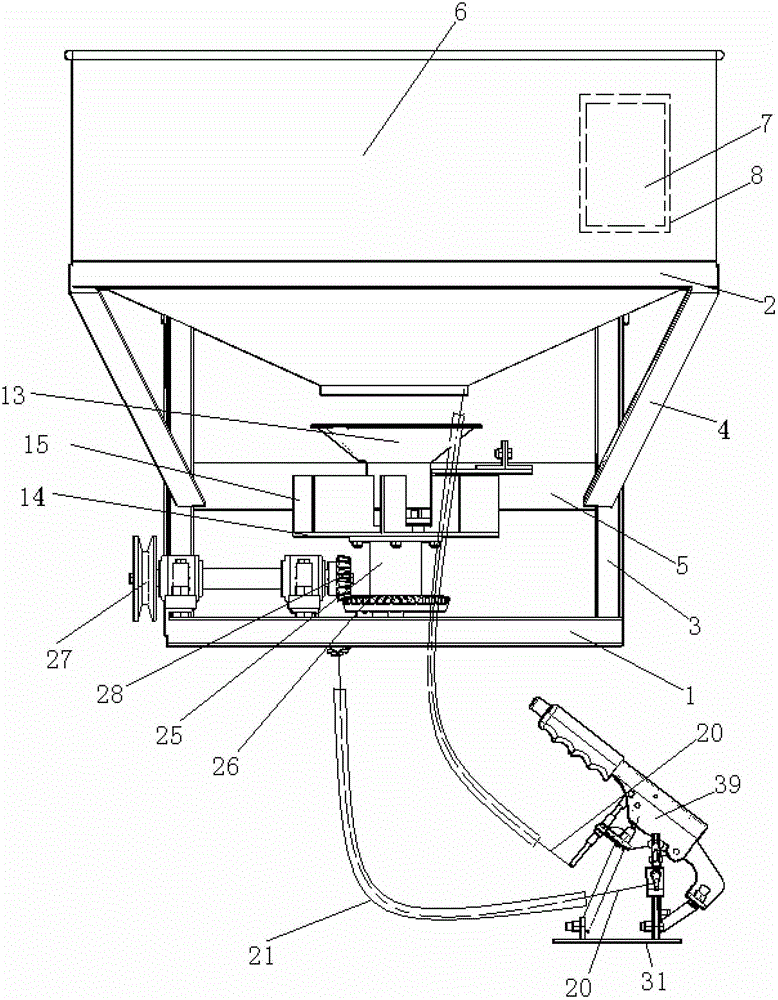

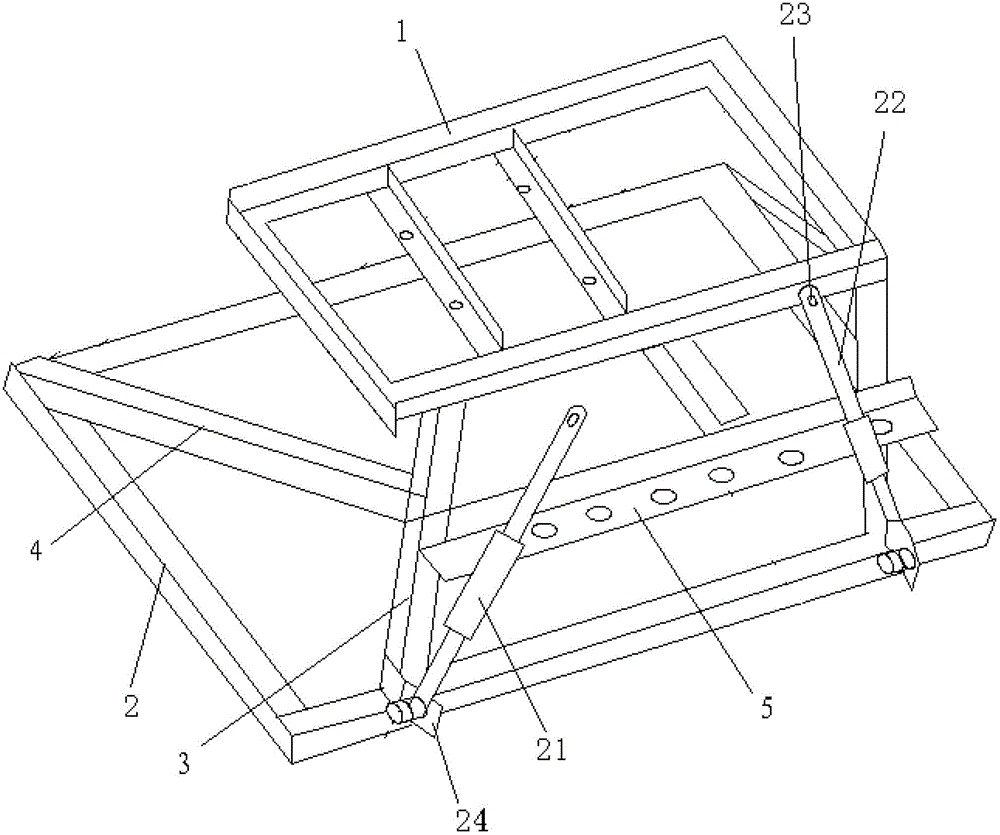

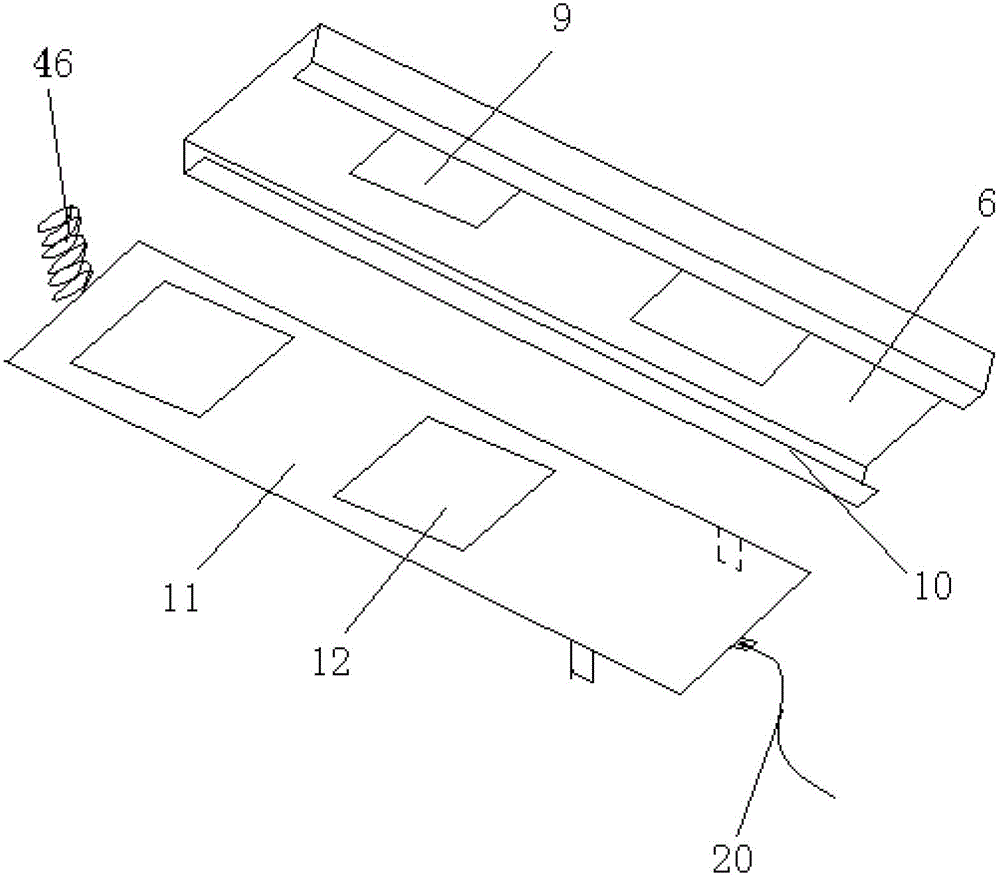

[0023] Referring to the accompanying drawings, a seeding and fertilizing machine that is conveniently adjusted and controlled includes a fixed frame, a charging box, a feeding station, a sowing turntable 14, a handle control mechanism, and a sowing rotation drive mechanism. The fixed frame includes a bottom frame 1 and a loading device The material box fixed frame 2, the bottom frame 1 and the charging box fixed frame 2 are fixed by the front column 3 and the rear tie rod 4, and the middle part of the front column 3 is provided with a fixed beam 5, and several installation holes are distributed on the fixed beam 5. The upper ends of the front pillars 3 are respectively hinged with adjustable pull rods; a charging box is installed on the fixed frame 2 of the charging box, and the charging box includes a box body 6, and the side of the box body 6 is provided with an observation port 7, and the observation port 7 is fixedly installed There is a transparent plastic plate 8 coordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com