Wind power sorting device

A wind separation and separation device technology, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of large space occupation, low separation efficiency, and excessive shape. Achieve the effects of low environmental pollution, high equipment integration, and power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

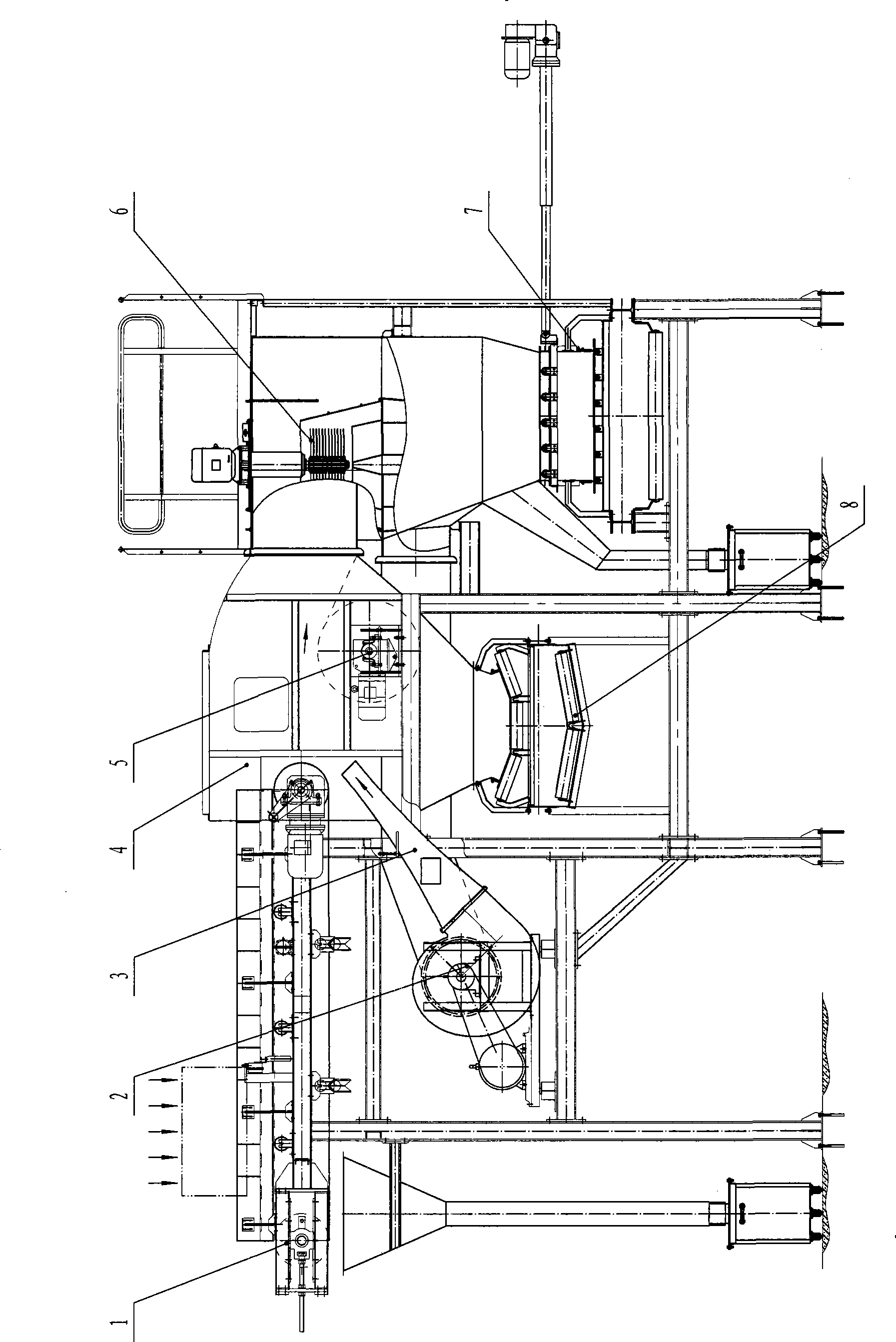

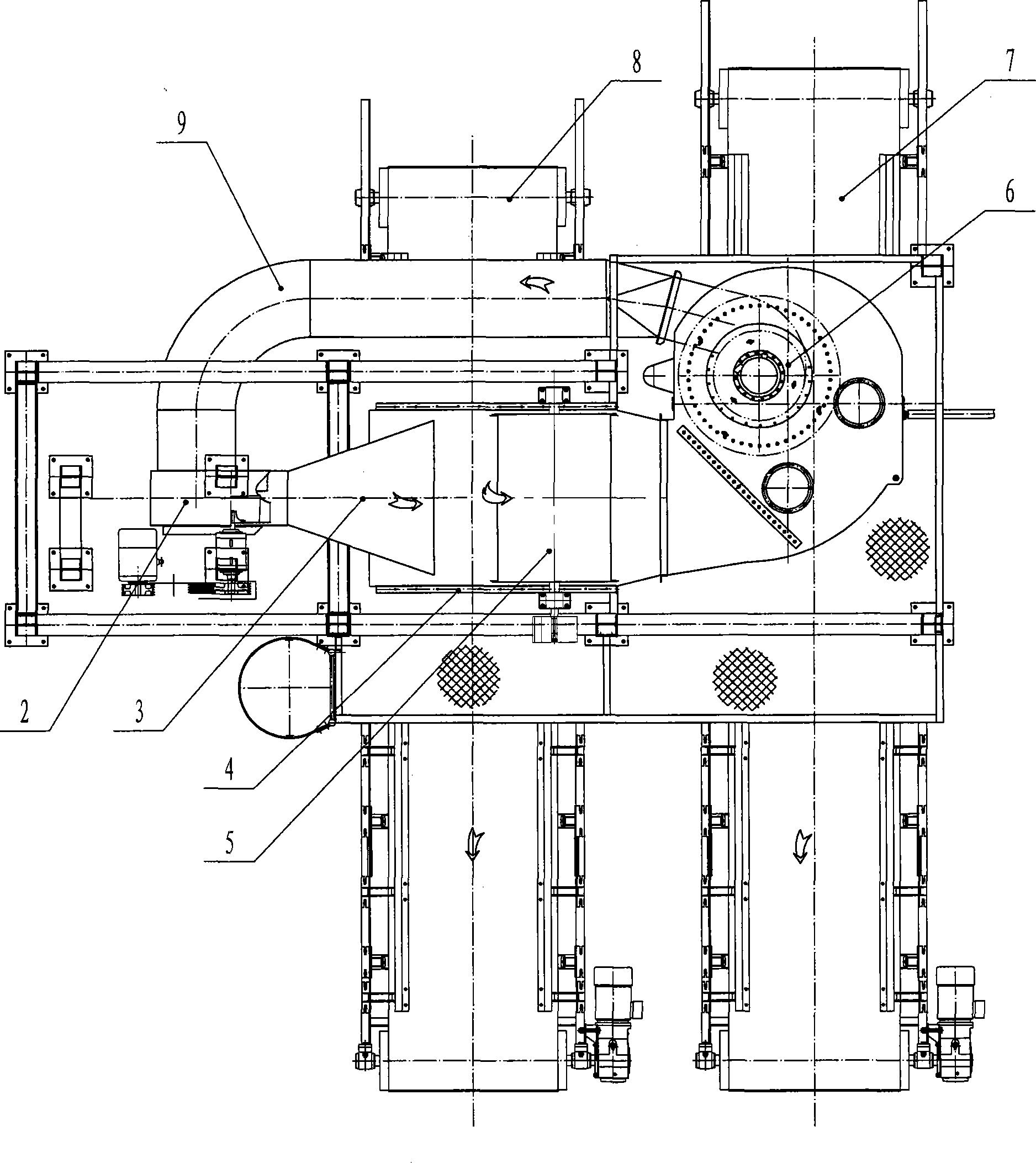

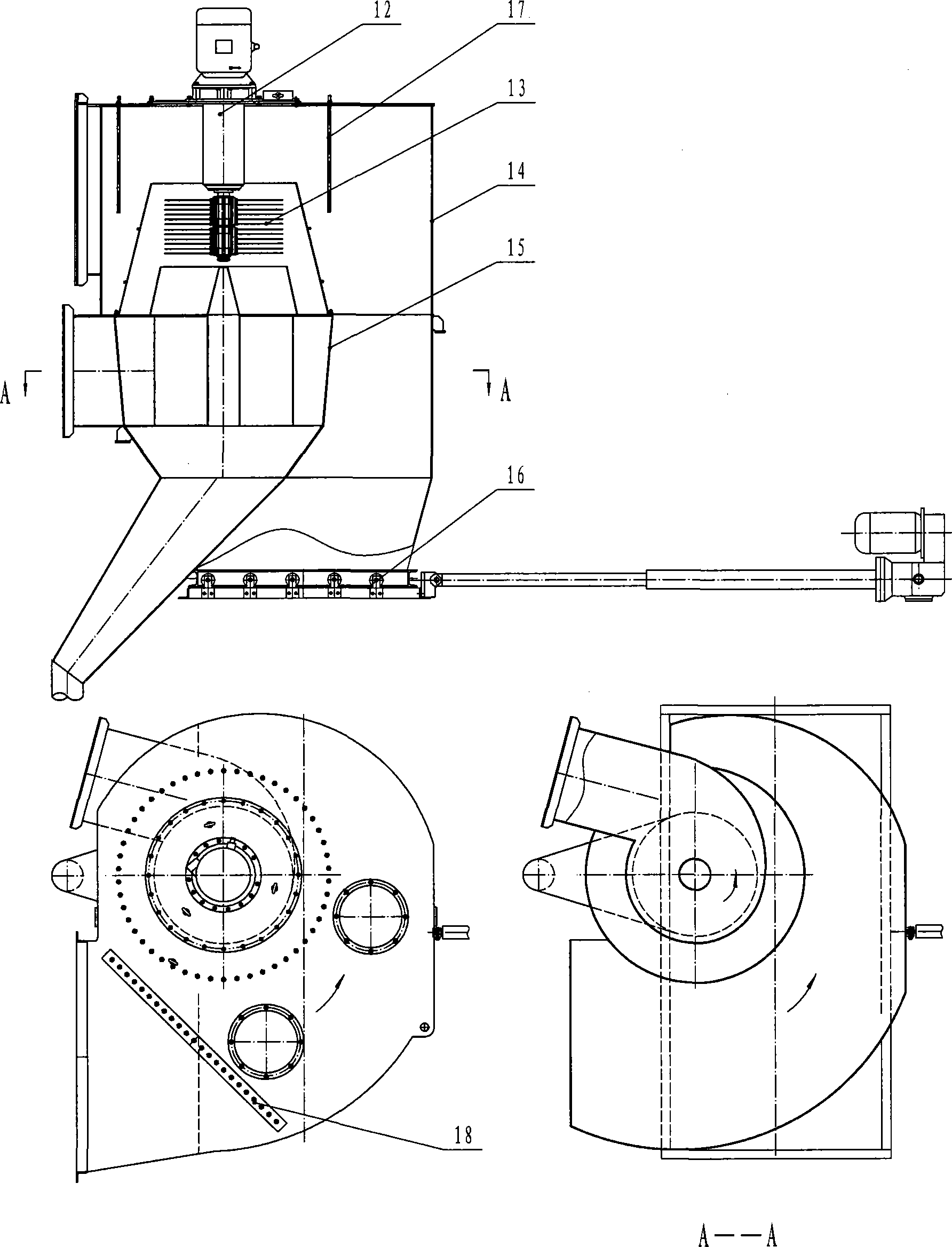

[0053] see figure 1 , 2, 3. This embodiment is a single-drum wind separation device designed according to the technical solution of the present invention. It includes a feed conveyor 1, a fan 2, an air distribution device 3, a winnowing room 4, a relay drum 5, a centrifugal sedimentation separator 6, a light material output conveyor 7, a heavy Material output belt conveyor 8, a group of return air duct 9, a set of bag filter. Centrifugal sedimentation separator 6 adopts electric push rod valve 16, and ring grate 17 and grid grate 18 are arranged on the top cover. These components are integrated on the same frame together with the maintenance platform. The scraper of the feeding conveyor 1 is placed near the tail roller, and connects the hopper and the slag truck under it. Below the centrifugal sedimentation separator 6, a slag car is also connected by bellows. A soft plastic strip is used at the position where the 4 blanking openings of the winnowing chamber are connected...

Embodiment 2

[0060] see Figure 4 , 5 , the present embodiment is a double-drum wind separation device designed according to the technical solution of the present invention. The difference from Embodiment 1 is that the winnowing chamber 4 is extended, and a secondary relay drum 10 and secondary heavy material output conveyor 11 are additionally arranged. The air distribution device 3 has increased a branch air pipe, and stretches into the winnowing room 4 between the two conveyors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com