Suspended type gas locking discharge valve

A discharge valve and air lock technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of granular materials stuck in the feed port, poor sealing performance of the discharge valve, damage to impellers and bearings, etc. Achieve the effect of improving pneumatic conveying capacity, short feeding interval time, and good load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

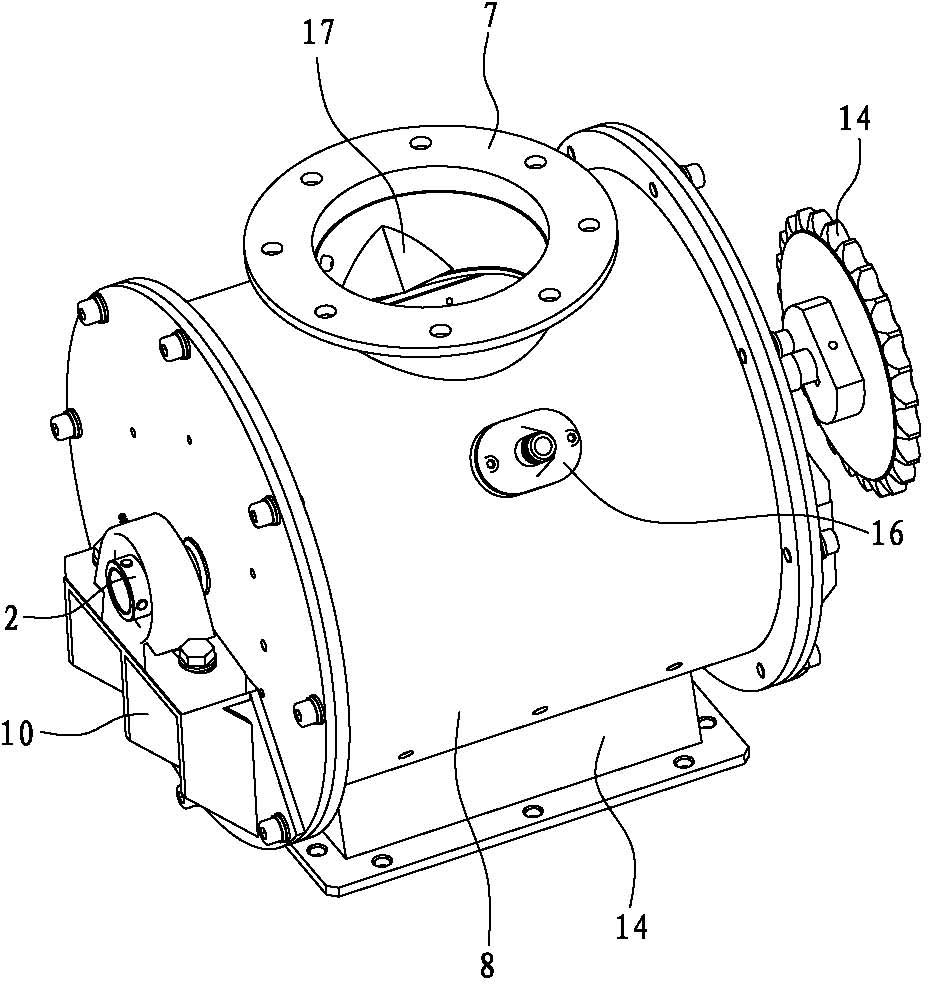

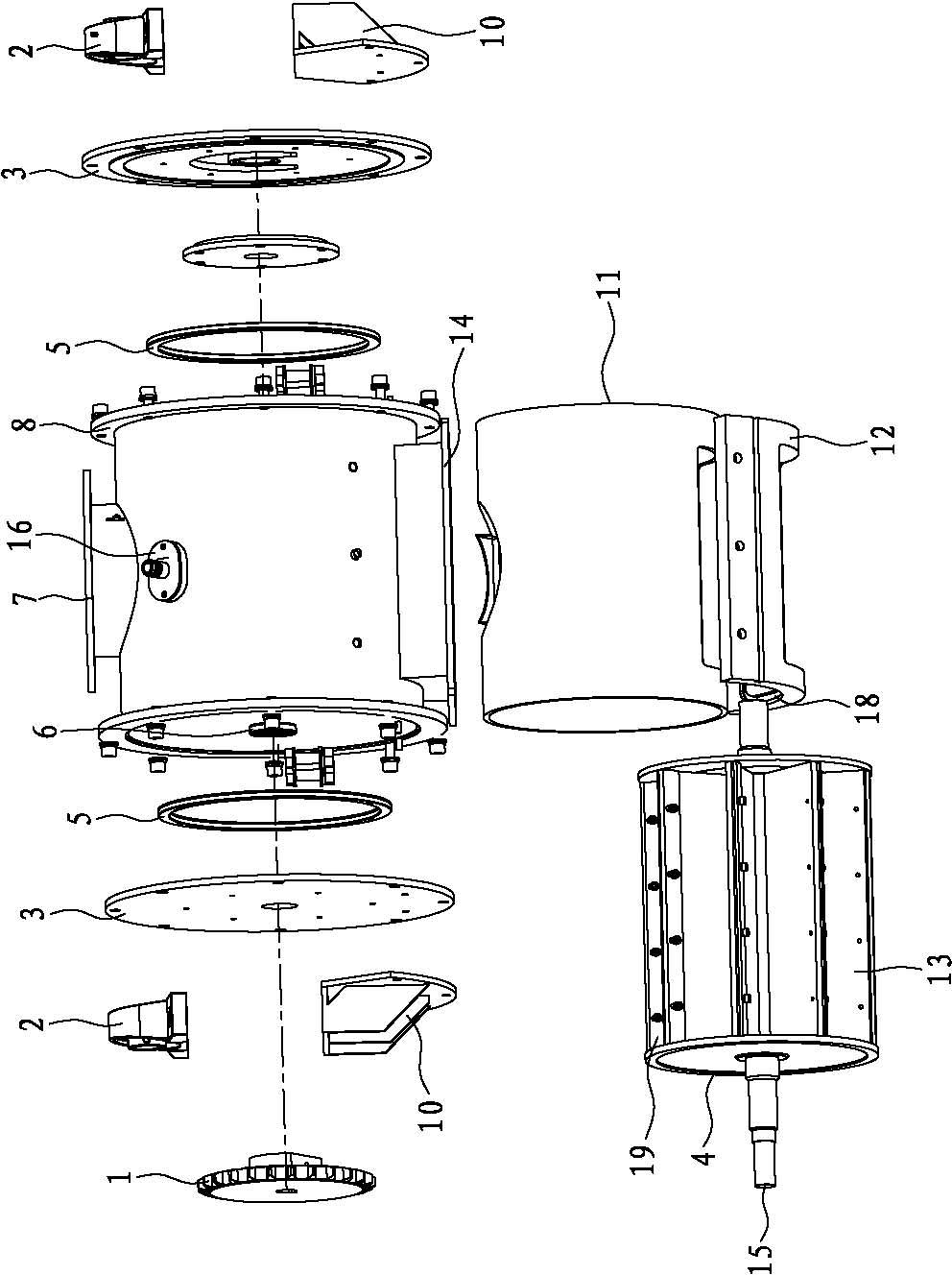

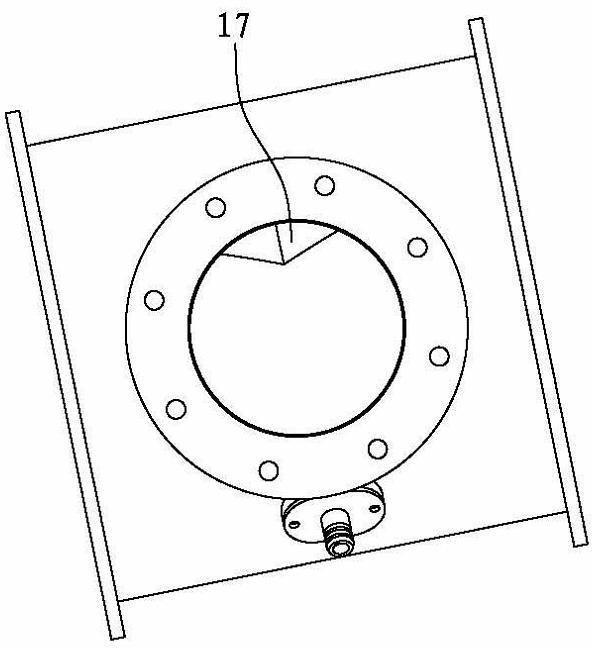

[0041] A suspended rotary unloading valve, comprising an outer shell 8, an inner shell 11, an impeller 13, a bearing seat 10, a rotating shaft 15, a transmission assembly 1, an end cover 3, an outlet of the unloading valve 14, an air guide port 16, and a triangular anti-seize structure 17 ;

[0042] The outer shell 8 and the inner shell 11 which are coaxially nested are both horizontally arranged cylindrical shells. The upper end of the outer wall of the outer shell 8 is provided with a feed port 7 to connect with the hopper. The feed port has an anti-jamming structure 17; There is a discharge valve outlet 14, which extends to the outside of the outer shell 8; the inner shell 11 is axially fixed on the outer shell 8 through the arc-shaped support pad 12 fixed on the inner bottom of the outer shell 8 and through the end cover 3; the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com