Feed and discharge processing method and feed and discharge processing device of flat-head machine and flat-head machine

A processing method and processing device technology, applied in metal processing, etc., to achieve the effects of improving processing efficiency, improving versatility, and avoiding material jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

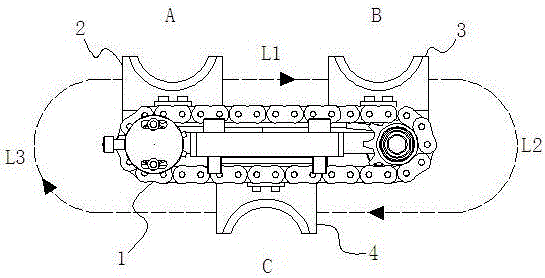

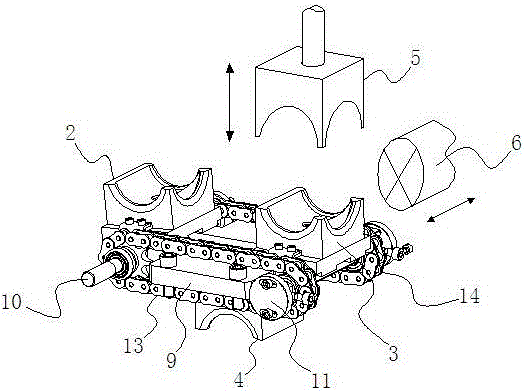

[0037] Embodiment 1: In this embodiment, the upper and lower material processing devices with three lower clamps are set to specify: as figure 1 and figure 2 Shown, a kind of loading and unloading processing method of flat head machine, described loading and unloading method is to arrange a belt transmission mechanism, three lower clamps are arranged on the transmission belt 1 of the belt transmission mechanism, and the transmission belt 1 top One end of the pipe fittings is set as the loading position A of the pipe fittings, the other end of the upper part of the transmission belt 1 is set as the processing position B of the pipe fittings, and the lower part of the transmission belt 1 is set as the unloading position C of the pipe fittings; Driven by the drive, each lower fixture circulates in turn from the loading position to the processing position to the unloading position and then to the loading position, so that the three steps of loading, processing and unloading of pi...

Embodiment 2

[0055] Embodiment 2: as Figure 9 As shown, compared with Embodiment 1, the difference is that an anti-jamming mechanism is provided on one side of the upper clamp 5, and the anti-jamming mechanism includes a connecting block 37, a compression spring 38 and a top block 39; the connecting block 37 is arranged on one side of the upper fixture 5, one end of the stage clip 38 is connected with the connection block 37, and the other end of the stage clip 38 is connected with the top block 39, when the upper fixture can cooperate with the lower fixture at the processing position, it will be positioned at the processing position. When the pipe fittings in the lower fixture at the position are clamped, the top block 39 is in contact with the pipe fittings, and the clip spring 38 is in a pressed state. During the flat end processing of pipe fittings, since the upper fixture needs to be pressed down to cooperate with the lower fixture to clamp the pipe fittings, after the upper fixture ...

Embodiment 3

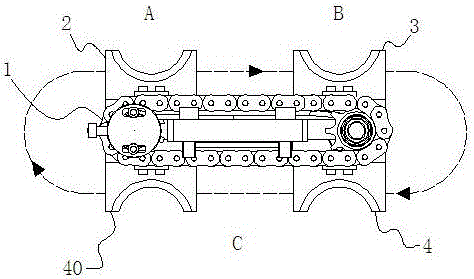

[0056] Embodiment 3: as Figure 10 As shown, compared with Embodiment 1, the difference is that there are four lower clamps arranged on the transmission belt, which are lower clamp one 2, lower clamp two 3, lower clamp three 4 and lower clamp four 40. Wherein, lower clamp one 2 is located at loading position A, lower clamp two 3 is located at processing position B, and lower clamp three 4 and lower clamp four 40 are both located at unloading position C.

[0057] To sum up, the present invention integrates the three steps of loading, processing and unloading of pipe fittings on the same transmission belt to complete simultaneously, that is, when the lower clamp located at the loading position performs loading of the pipe fittings, the clamp located at the processing position carries out For flat head processing, the pipe fittings at the unloading position are unloaded at the same time, which greatly shortens the processing time of pipe fittings and greatly improves the processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com