Electronic fitting testing pneumatic press

An accessory and electronic technology, which is applied in the field of electronic product testing, can solve the problems of manual work, high human energy consumption, and slow detection speed, and achieve the effects of reducing mental stress, accurate sorting results, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described below in conjunction with accompanying drawing and embodiment:

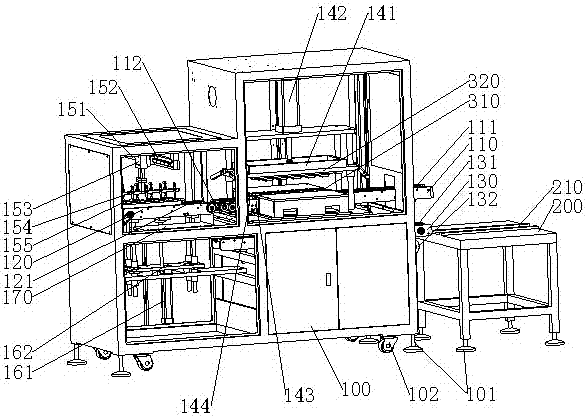

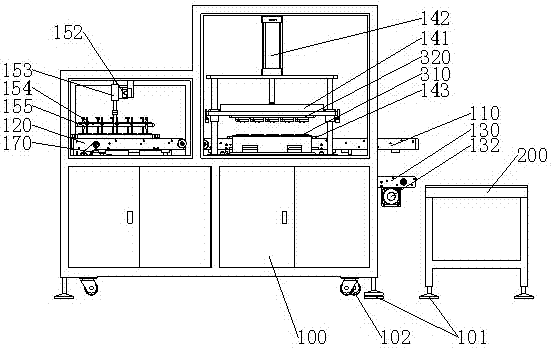

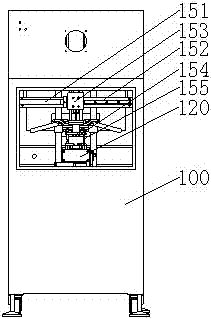

[0033] Such as Figure 1-3 As shown, a pneumatic press for testing electronic accessories includes a frame 100 and an operating table 200, and a transparent or translucent switch door is provided on the side of the frame 100.

[0034] Both the bottom of the frame 100 and the operating table 200 are provided with a base 101 , and the bottom of the frame 100 is also provided with rollers 102 . The rollers 102 can realize the moving of the entire frame 100 , and after the moving action is completed, the base 101 can support the entire frame 100 to prevent the frame 100 from sliding due to the action of the rollers 102 . The mutual cooperation effect of the two is better than that of the existing universal wheel, and the long-term use of the universal wheel may cause the stuck structure to wear out, and cannot play a good locking effect.

[0035] A controller and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com