Device for manufacturing prefabricated optical fiber core rod based on base pipe outer diameter maintaining and correcting control and method for manufacturing prefabricated optical fiber core rod by device

A prefabricated core and base tube technology, applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problem of not completely solving the axial non-uniformity of the outer diameter of the glass tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

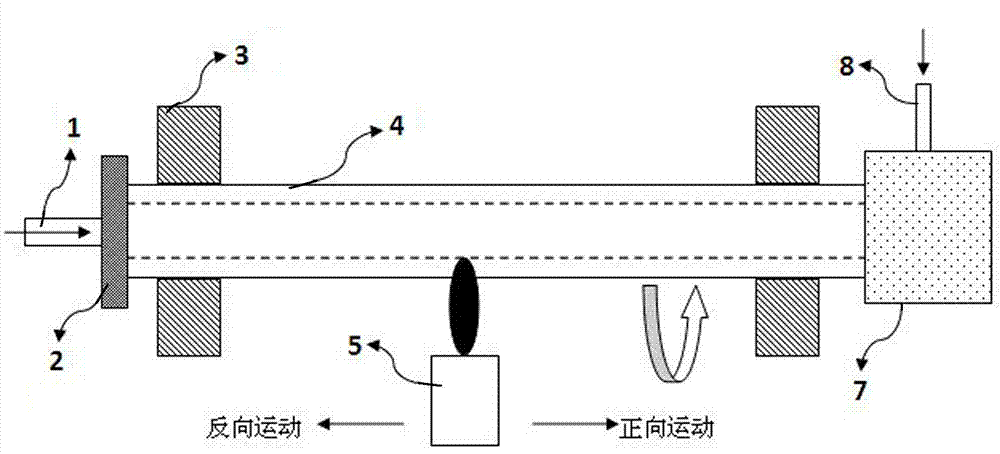

[0090] Heraeus F320-08 quartz base tube 4 was selected as the deposition base tube, with an outer diameter of 31.7 mm, an inner diameter of 26.3 mm and a length of 1200 mm, and the quartz base tube was placed on a chemical vapor deposition (MCVD) lathe chuck 3 .

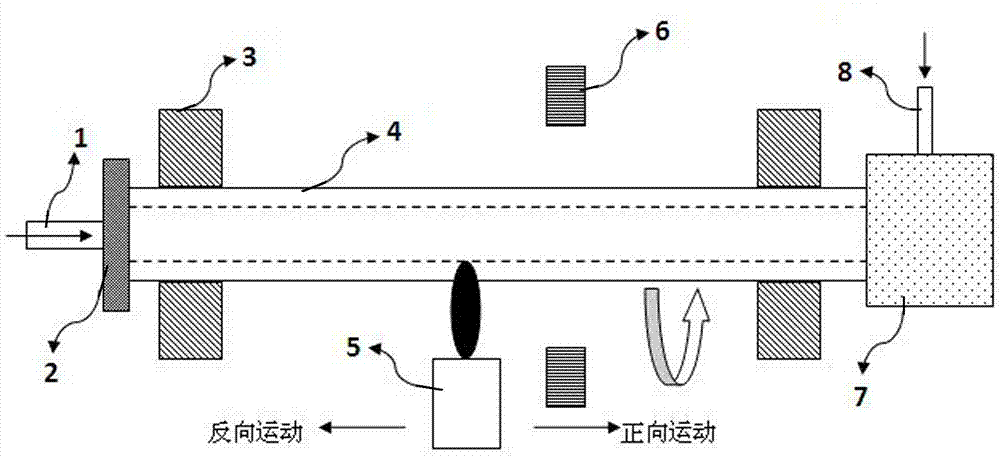

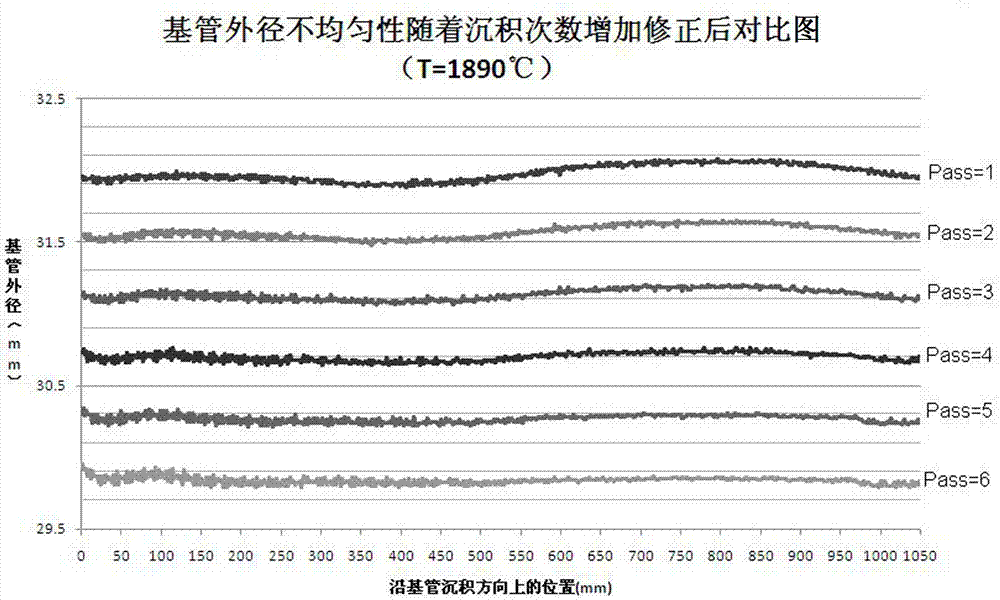

[0091] The mixed gas composed of oxygen, SF6 and chlorine gas is passed into the quartz base tube 4 . In the forward movement, it reacts with the inner wall of the quartz base tube 4 under the action of the oxyhydrogen flame, the temperature is 1850°C, flame polishing and corrosion are carried out, and the oxyhydrogen flame torch 5 goes back and forth once. At the same time, the outer diameter measuring instrument 6 moves together with the oxyhydrogen flame torch 5, and the forward moving speed is 145 mm / min. The measuring point of the outer diameter measuring instrument 6 is 45 mm away from the center of the oxyhydrogen flame torch 5. The outer diameter is set to 31.7mm. The actual outer diameter data of the qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com