A method for manufacturing optical fiber prefabricated core rods based on the maintenance and correction control of the outer diameter of the base tube

A prefabricated core and base tube technology, applied in the direction of manufacturing tools, glass manufacturing equipment, etc., can solve the problem of not completely solving the problem of the axial non-uniformity of the outer diameter of the glass tube, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

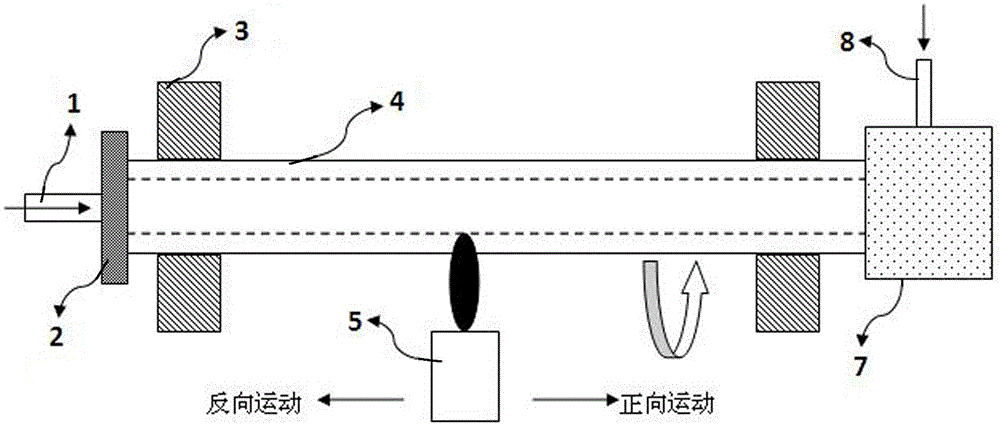

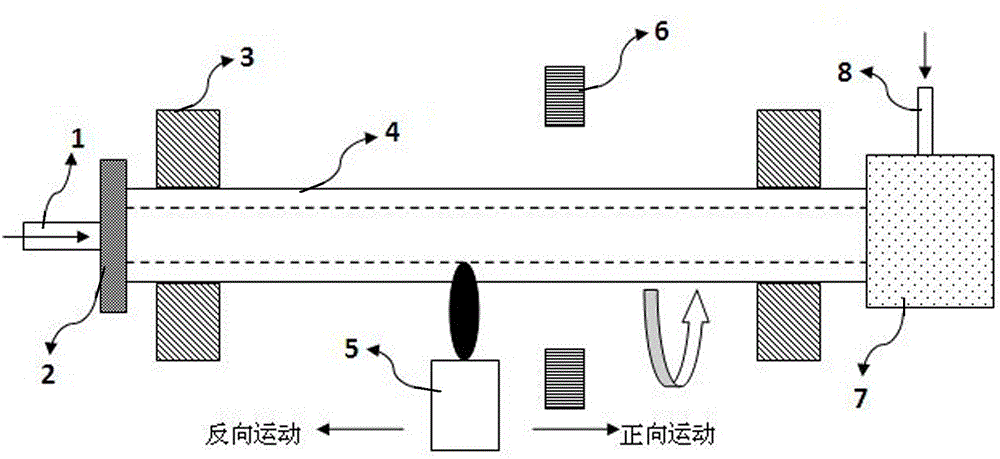

Method used

Image

Examples

Embodiment

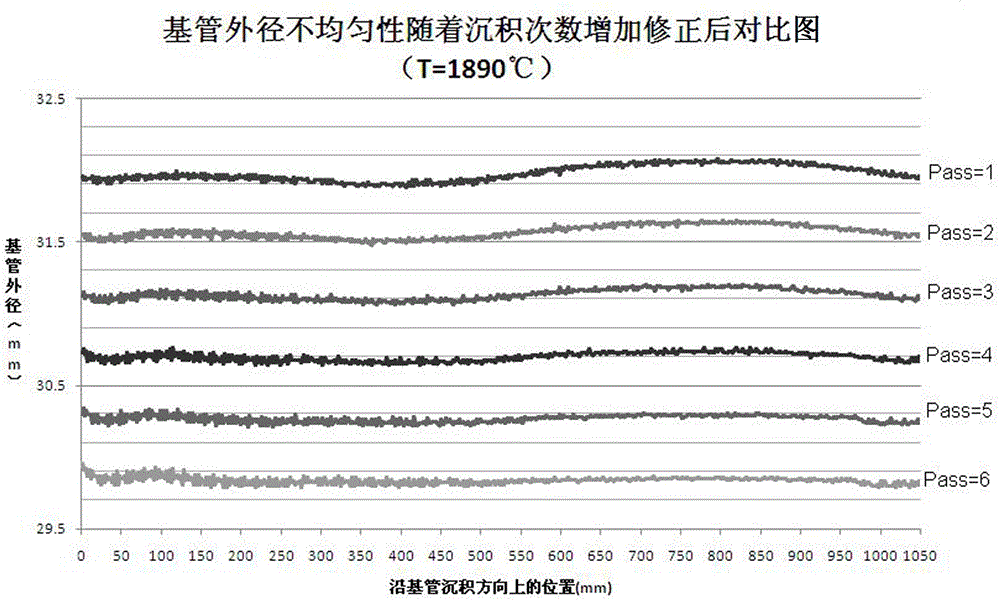

[0090] A Heraeus F320-08 quartz substrate tube 4 was selected as the deposition substrate tube, with an outer diameter of 31.7mm, an inner diameter of 26.3mm, and a length of 1200mm, and the quartz substrate tube was placed on the chuck 3 of a chemical vapor deposition (MCVD) lathe.

[0091] A mixed gas composed of oxygen, SF6 and chlorine is passed into the quartz substrate tube 4 . During the forward movement, it reacts with the inner wall of the quartz substrate tube 4 under the action of the oxyhydrogen flame at a temperature of 1850° C. for flame polishing and corrosion, and the oxyhydrogen flame torch 5 goes back and forth once. Simultaneously, the outer diameter measuring instrument 6 moves together with the oxyhydrogen torch 5 at a forward moving speed of 145 mm / min, and the measuring point of the outer diameter measuring instrument 6 is 45 mm from the center of the oxyhydrogen torch 5 . The outer diameter setting value is 31.7mm. The actual outer diameter data of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com