Pipeline geometric size measuring machine

A technology of geometric dimensions and measuring machines, applied in the field of measuring equipment, can solve problems such as restricting failure modes, inability to locate accurately, and research on damage mechanisms, and achieve the effects of convenient operation, improved positioning accuracy, and high work reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

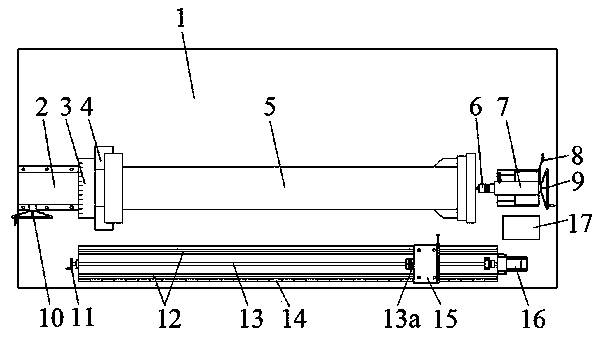

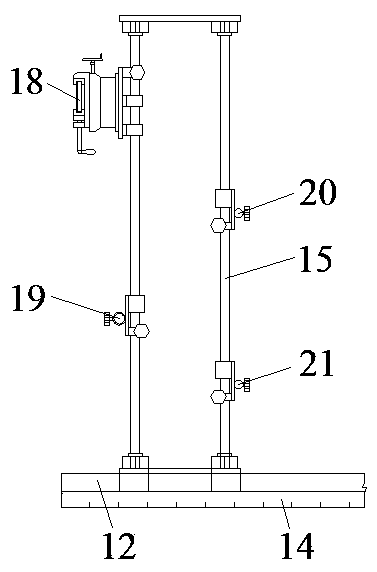

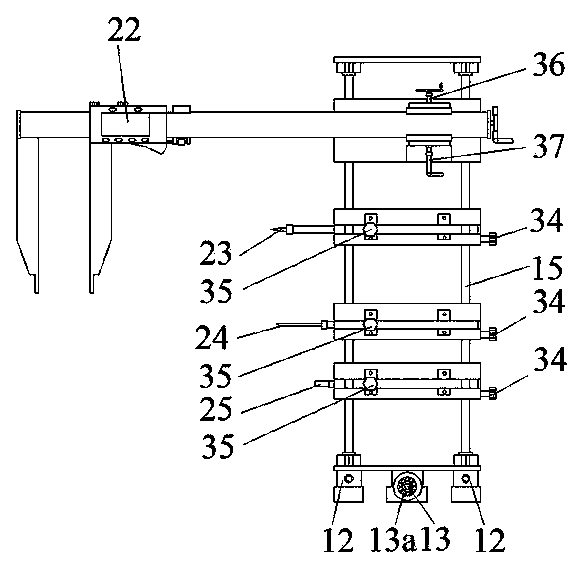

[0015] figure 1 , 2 , 3 shows the layout of a measuring machine for pipe geometry. In the figure, the measuring machine for pipeline geometric dimensions includes a pipeline clamping device, a measuring device and a control box 17 arranged on an operating platform 1. The pipeline clamping device adopts a headstock mechanism and a tailstock mechanism to support the pipe to be measured 5, and the headstock mechanism It includes the spindle box 2, the circumferential scale 3, the chuck 4 and the spindle driving handwheel 10. The spindle driving handwheel 10 drives the spindle with the chuck 4 to rotate through the reduction gear set in the spindle box 2. The tailstock mechanism includes the top 6 , tailstock 7, top locking device 8 and tailstock handwheel 9, the tailstock handwheel 9 drives the top 6 to move axially through the threaded transmission mechanism. The measuring device is arranged on one side of the pipe clamping device. Two guide rails 12 parallel to the axis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com