Holographic detection system for steel wire rope

A detection system, steel wire rope technology, applied in the direction of measuring devices, optical testing flaws/defects, elevators, etc., can solve the problems affecting the quality of steel wire rope detection, low detection efficiency, high labor intensity, etc., to improve the degree of refinement and detection accuracy , Avoid false detection and missed detection, and the effect of high damage detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

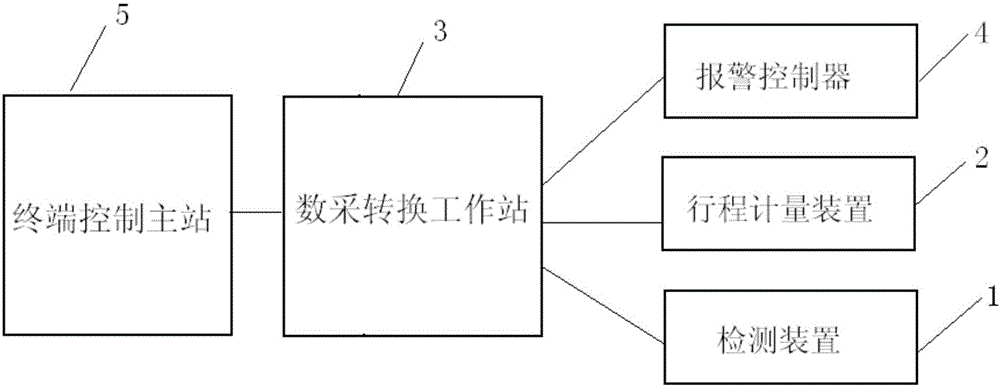

[0046] see figure 1 , a steel wire rope holographic detection system provided by an embodiment of the present invention includes a detection device 1, a stroke measurement device 2, a data acquisition conversion workstation 3, an alarm controller 4, and a terminal control master station 5; the data acquisition conversion workstation 3 is connected with the Terminal control master station 5 (i.e. implement central data analysis and feedback control), detection device 1, stroke measurement device 2, alarm controller 4 communication interface connection and wire electrical connection; see figure 1 The schematic diagram of the data acquisition and conversion workstation 3 is connected with the detection device 1, the stroke measurement device 2, and the alarm controller 4 respectively, that is, to realize signal transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com