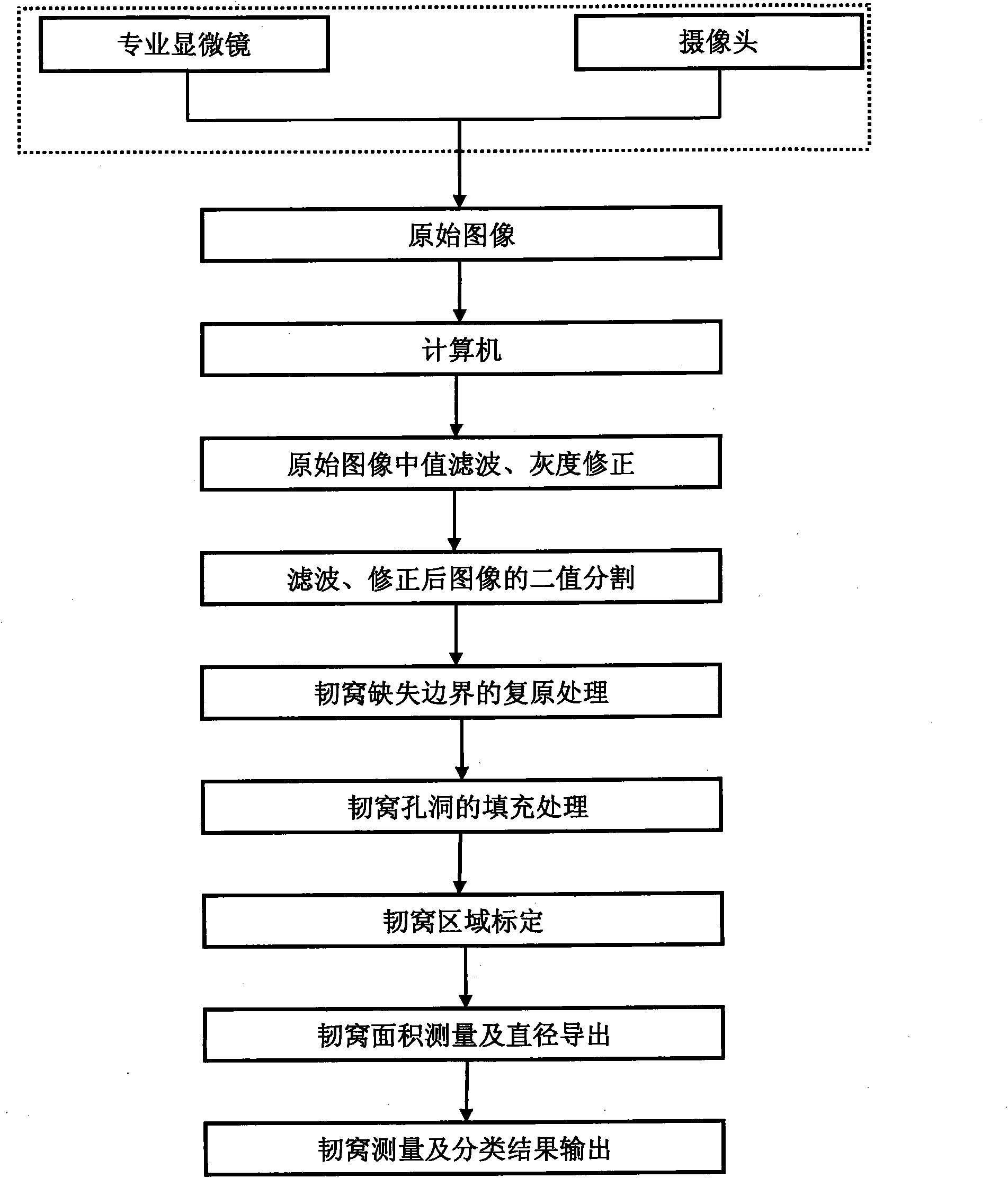

Method and device for automatically restoring, measuring and classifying steel dimple images

A classification method and automatic recovery technology, which can be used in measurement devices, image analysis, image enhancement, etc., and can solve problems such as low efficiency and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

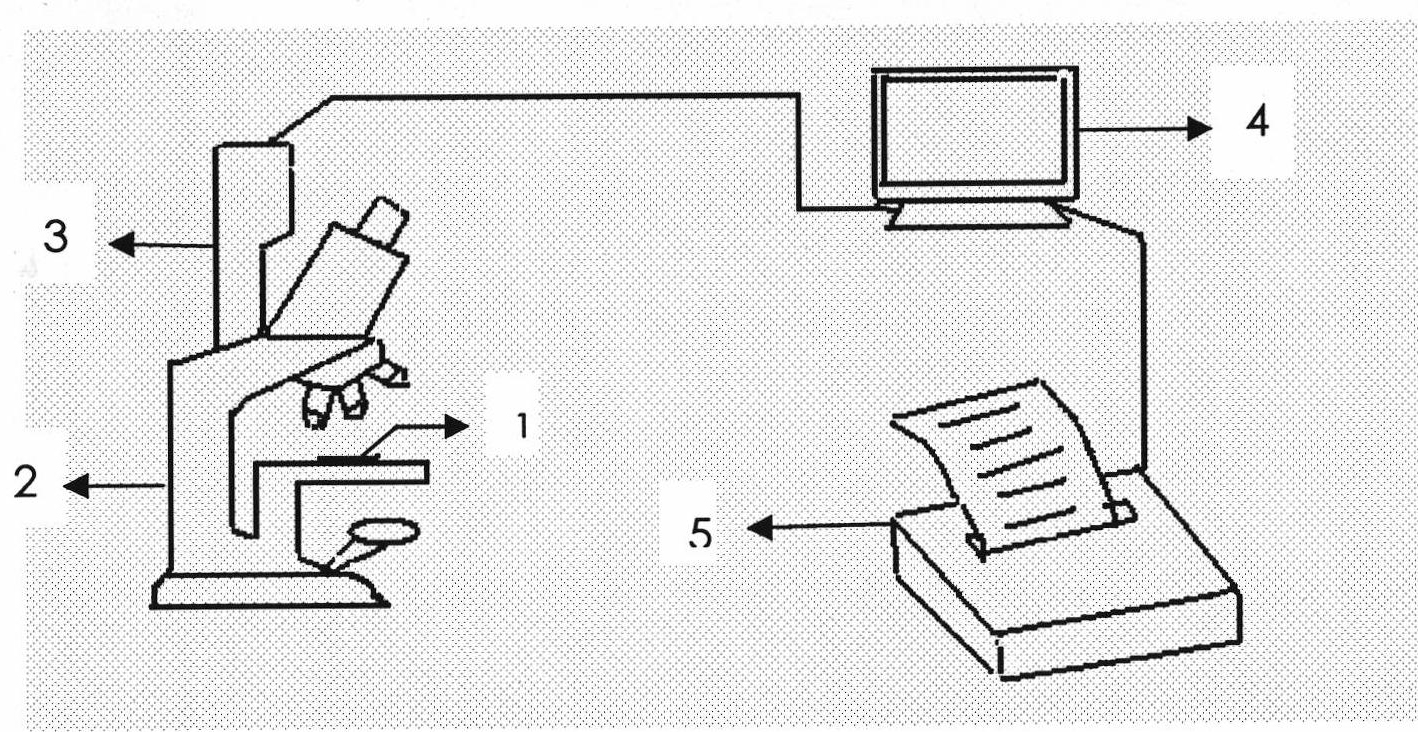

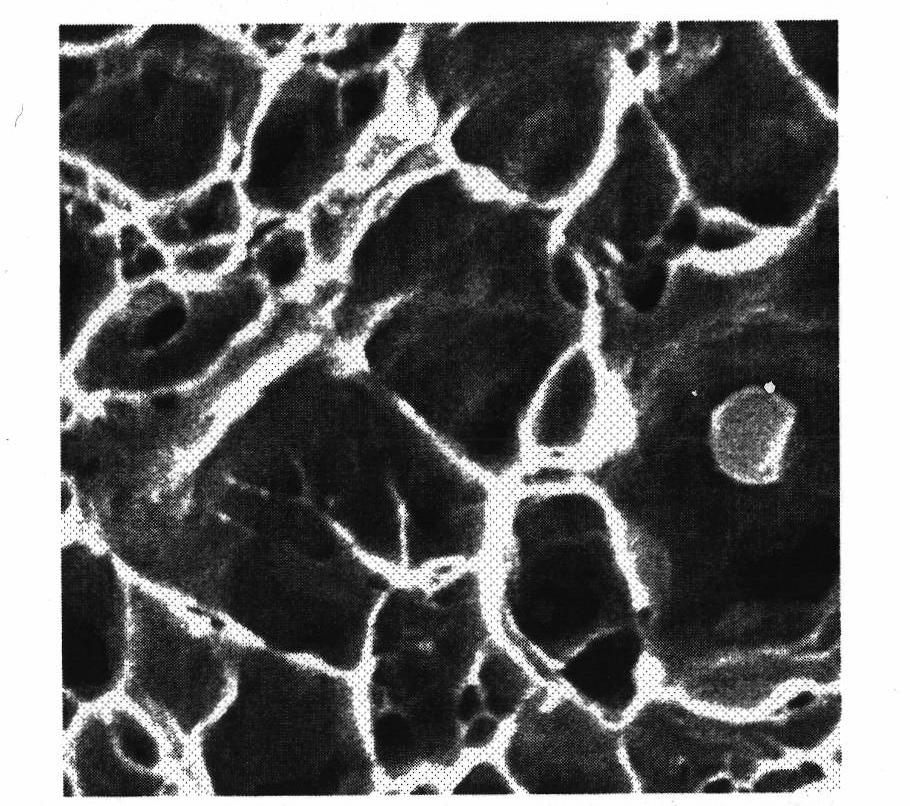

[0079] Use the image acquisition system to obtain the original image of steel dimples. The hardware of the image acquisition system is as follows: figure 2 Shown: 1--steel sample, 2--professional microscope, 3--camera (with image acquisition card included), 4--computer, 5--printer. The specific steps of image acquisition are to use a professional microscope to adjust the image to a suitable focal length, take a picture and store it in the image acquisition card when the image is clearest (such as image 3 shown), and then the subsequent image preprocessing can be performed.

[0080] In the preprocessing, the target image is firstly denoised by using the median filter to remove isolated noise points such as pulse noise and salt and pepper noise in the image, and to prevent blurred edges. The effect of the median filter is as follows: Figure 4 shown. In order to further process the original image into a clear image with a lot of useful information, it is also necessary to pe...

Embodiment 2

[0133] Such as Figure 12 The original image shown is the dimple image of ultra-fine grain steel. The dimples are extremely dense and small in size. It is very difficult to measure and analyze the dimples by manual mode, and it is also difficult to obtain accurate measurement classification. result. The processing process of the present invention is as follows: firstly carry out median filtering, grayscale histogram correction and adaptive fuzzy threshold binary segmentation to the target image, and the processing effect is as follows: Figure 13 As shown; and then the binary image is processed for missing boundary restoration and hole filling, and the processing effect is as follows Figure 14 As shown; after the area calibration of each dimple, measure the dimple area and find its diameter, and output the dimple measurement and classification results, as shown in Figure 15 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com