Cylinder on-line diameter measurement apparatus and measurement method thereof

A technology for diameter measurement and cylinders, which is applied in the field of cylinder diameter measurement devices, can solve problems such as inability to detect cylinders, and achieve the effects of improving measurement accuracy, reducing costs, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

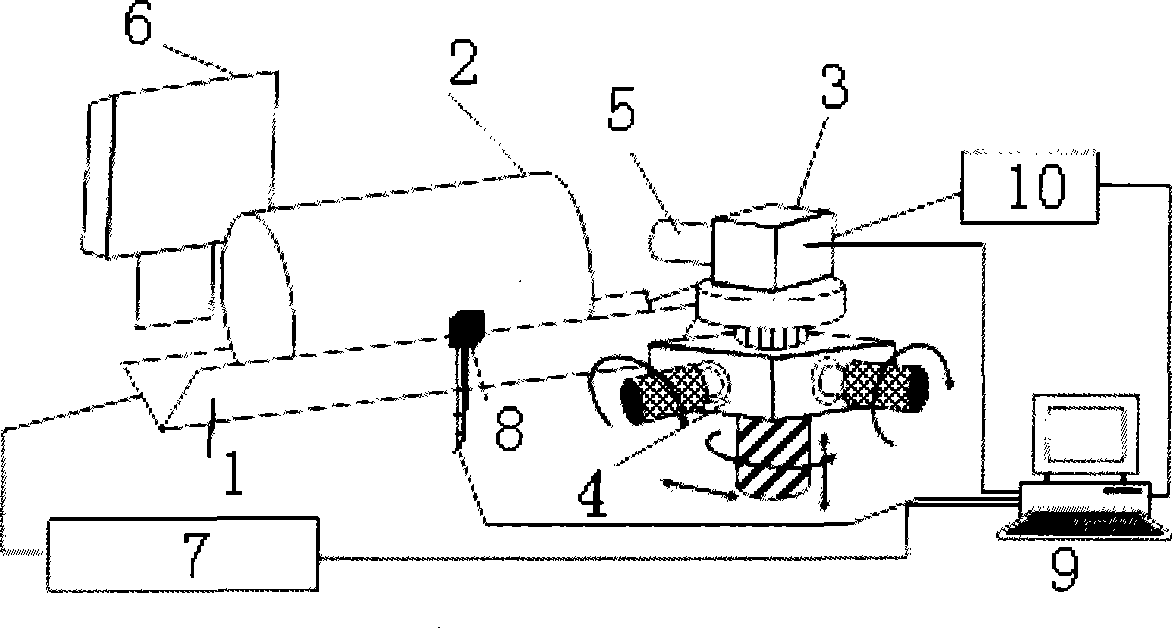

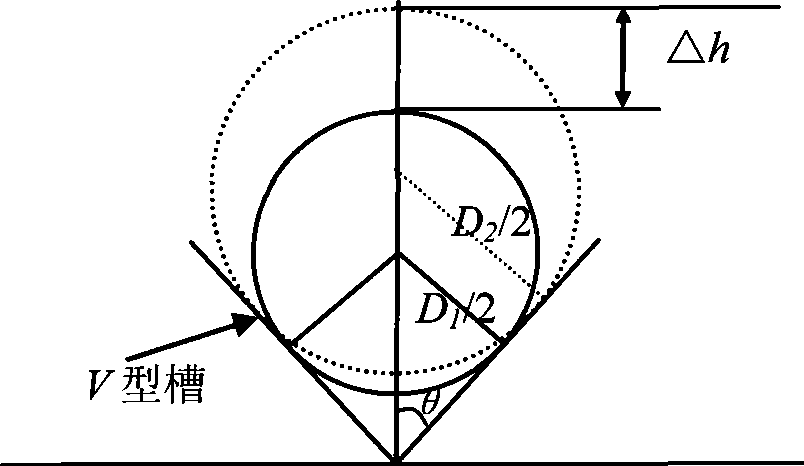

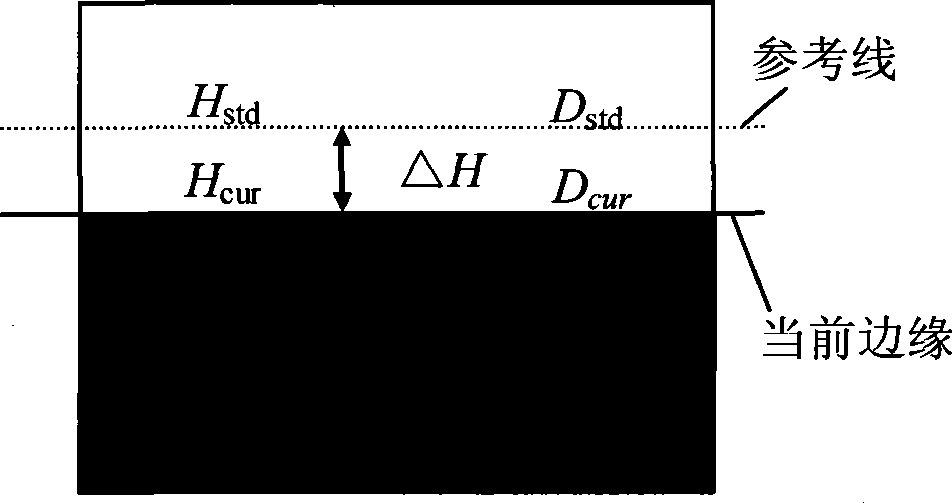

[0022] The structural representation of measuring device of the present invention is as figure 1 shown. The measured cylinder 2 is placed on the V-groove 1 conveyor belt with a smooth surface, and the motor drive 7 is controlled by the computer 9 to move at a constant speed; The image on the upper edge of the cylinder 2 is collected, stored in the computer 9 through a digital device such as a capture card, and waits for the next step to be processed. The imaging system is placed on the pan-tilt 4 with multiple degrees of freedom, and the position of the imaging system can be adjusted conveniently. A backlight 6 is installed on the opposite side of the imaging system to transmit uniform high-brightness light, which can enhance the edge information of the cylinder 2, and obtain the position of the CCD image sensor where the edge of the cylinder 2 is located by simple image processing; because the V-shaped groove 1 is used, the cylinder 2 The imaging position of the edge on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com