Method and device for measuring dynamic impact load of wheel-side motor bearing

A wheel-side motor and impact load technology, which is used in measuring devices, testing of mechanical components, and testing of machine/structural components, etc., can solve the problem of inability to effectively simulate road vibration of motors, and achieve real and reliable vibration input, operability The effect of strong and reliable vibration excitation source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

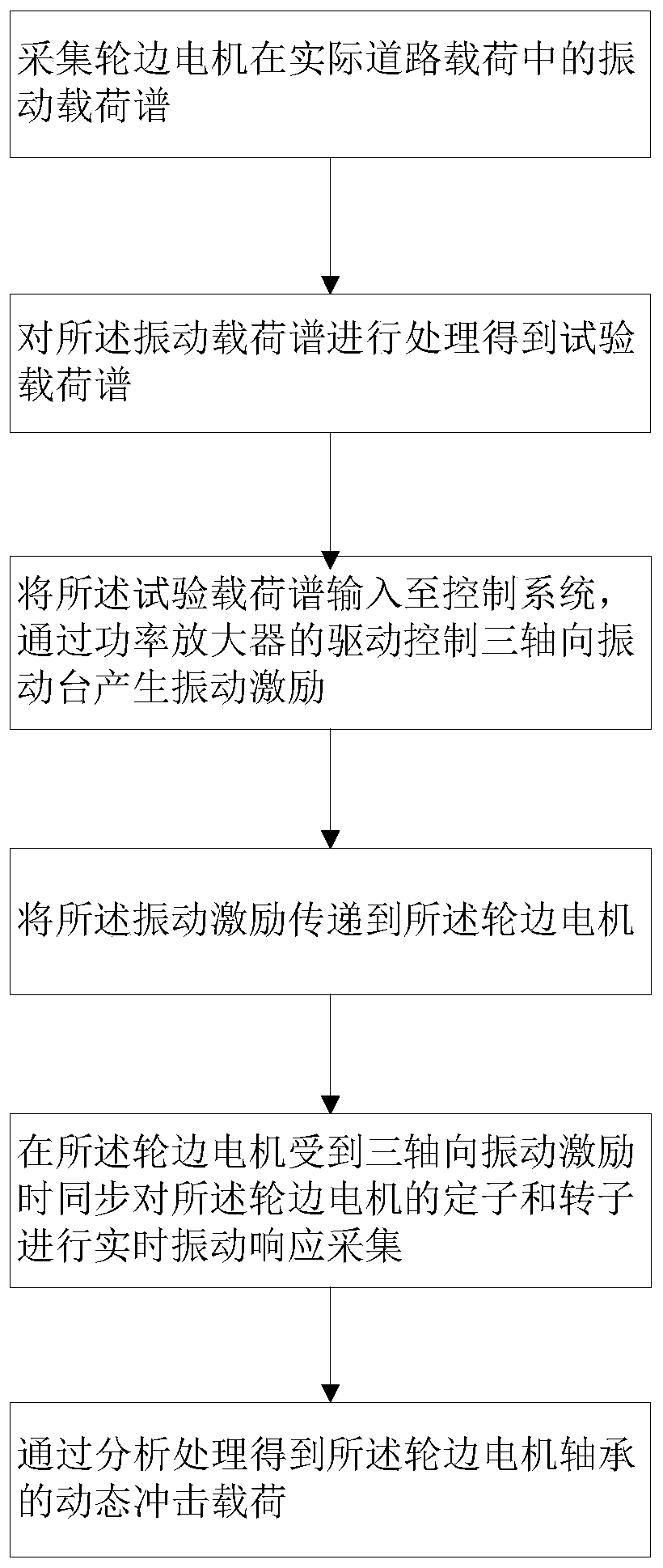

[0023] Such as figure 1 As shown, the present embodiment provides a method for measuring the dynamic impact load of the wheel motor bearing, which includes the following steps: Step S1: collecting the vibration load spectrum of the wheel motor under the actual road load, and performing the vibration load spectrum on the vibration load spectrum Process to obtain the test load spectrum; Step S2: input the test load spectrum to the control system, fix the wheel motor on the three-axis vibration table, use the test load spectrum to drive the three-axis through the power amplifier The vibration table simultaneously produces a triaxial vibration load consistent with the actual road vibration environment; Step S3: collect the vibration responses of the stator and rotor of the wheel motor in real time, and analyze and process to obtain the dynamic impact load of the motor bearing.

[0024] The method for measuring the dynamic impact load of the wheel motor bearing in this embodiment, ...

Embodiment 2

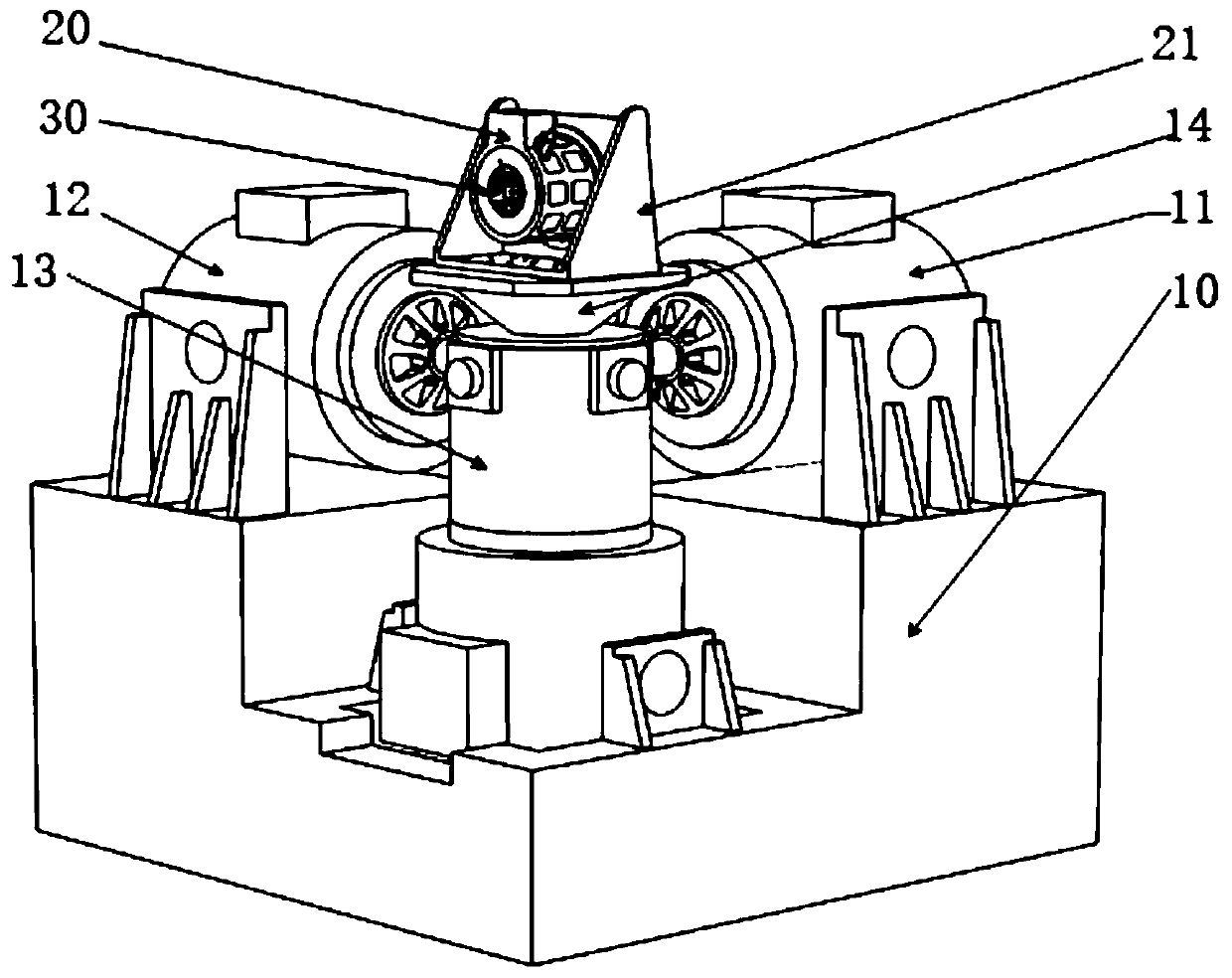

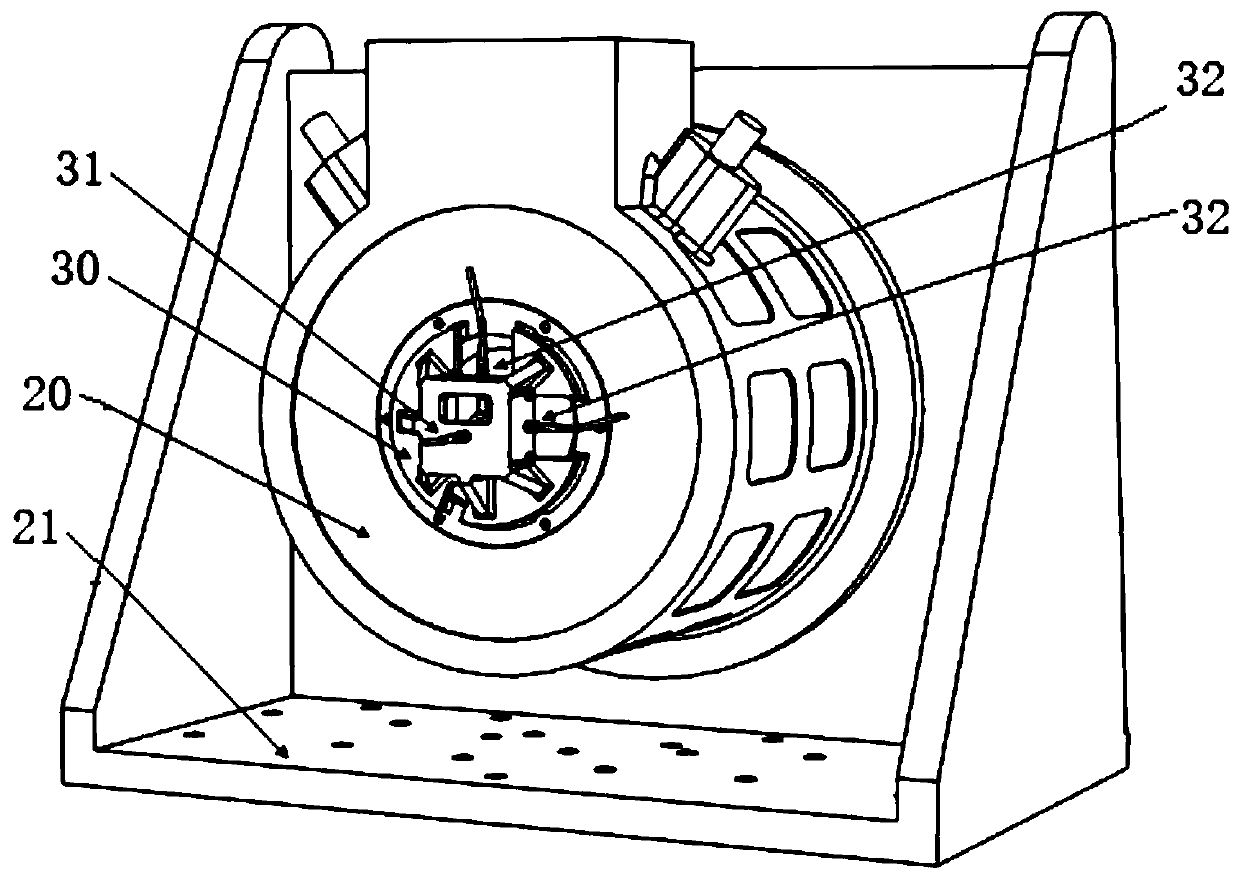

[0030] Such as figure 2 with image 3As shown, the present embodiment provides a measuring device for the dynamic impact load of the wheel motor bearing, including a first acquisition and processing system for collecting the vibration load spectrum of the wheel motor in the actual road load, and for the vibration load The spectrum is processed to obtain the test load spectrum; the control system, the control system is connected to the first acquisition and processing system, and the test load spectrum is input to the control system, the control system is connected to the power amplifier, and the power The amplifier is connected to the three-axis vibration table, and the test load spectrum is used to drive the three-axis vibration table 10 through the power amplifier to generate three axial excitation forces at the same time, and the wheel motor 20 is placed on the On the three-axis vibrating table 10; the second collection and processing system, the second collection and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com